Design Temperature vs. Process Temperature:Which One to Follow?

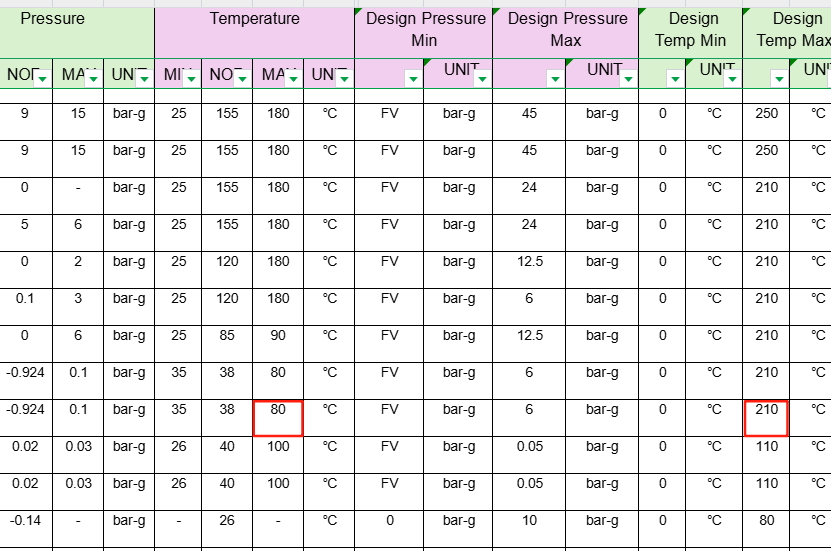

In industrial equipment selection and procurement, design temperature (Design Temperature) and process temperature (Process Temperature / Operating Temperature) are often confused.

Although this question seems simple, it involves multiple aspects including engineering design principles, material science, long-term equipment reliability, and industrial safety. Understanding these concepts helps engineers, procurement teams, and suppliers align their expectations and avoid risks in equipment selection and operation.

1. Difference Between Design Temperature and Process Temperature

1.1 Design Temperature (Design Temperature)

Design temperature is the maximum or minimum temperature that equipment is specified to safely withstand during the design stage. It is not merely a theoretical value but a core basis for engineering design. Design temperature is generally higher than the actual operating temperature and includes a safety margin to ensure the equipment can operate safely under extreme conditions.

Design temperature directly affects several critical factors:

- Material Selection: Temperature impacts metal strength, elastic modulus, and corrosion resistance. High temperatures may cause expansion, softening, or accelerated aging. Ignoring design temperature can severely compromise long-term reliability.

- Seals and Connections: High temperature affects the physical properties of seals, influencing sealing reliability. Design temperature guides material selection and structural design to prevent leakage or structural damage.

- Structure and Thickness Calculations: Design temperature determines wall thickness, flange connections, and pressure-bearing capacity. Engineering standards require maintaining safety margins even under extreme temperatures.

- Electronic Components and Sensor Layout: Temperature variations can affect the stability of internal electronics. Design temperature ensures components remain stable and functional at high temperatures.

In short, design temperature establishes the baseline for safe operation throughout the equipment’s lifecycle.

1.2 Process Temperature (Process / Operating Temperature)

Process temperature is the actual temperature of the medium under normal operating conditions. It is important for operational monitoring and process control but cannot serve as the basis for structural safety or equipment selection.

Although process temperature reflects daily operations, it may vary briefly due to:

- Instantaneous thermal shocks during startup or shutdown

- High-temperature steam during cleaning, sterilization, or disinfection

- Accidental inflow of high-temperature media due to heat exchanger or valve failures

Relying solely on process temperature for equipment selection may cause the device to exceed its limits during such events, resulting in seal failure, probe deformation, sensor drift, or electronic damage.

Thus, process temperature serves as an operational reference, while design temperature is the safety baseline.

2. High-Temperature Effects on Equipment Performance and Safety

Even if the site temperature is only 80°C, high-temperature design remains essential. The main impacts of high temperature on industrial level switches include:

- Probe Vibration Characteristics: Elevated temperatures can alter the elastic modulus and vibration frequency of probes, affecting measurement accuracy. Devices selected according to design temperature maintain stable vibration and reliable detection under extreme conditions.

- Seal Aging and Failure Risk: High temperatures accelerate seal degradation, leading to leakage or probe-tank interface failure. Design-temperature-based material and structural selection ensures long-term operational safety.

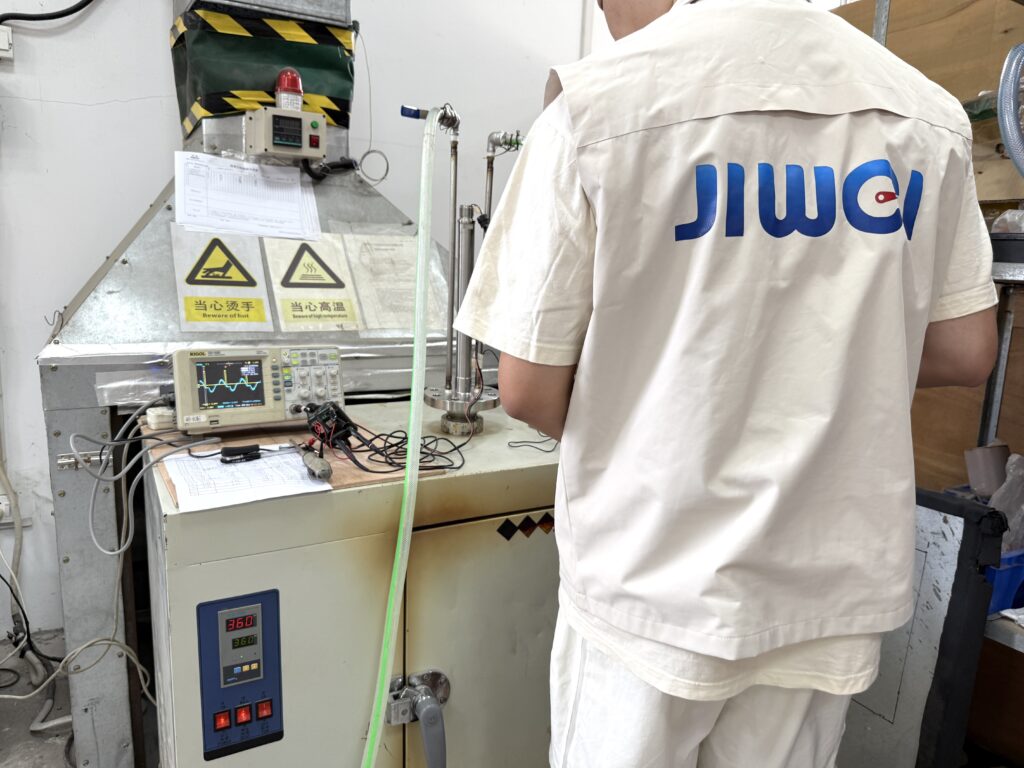

- Electronic Component Stability: Excessive heat can cause circuit drift or failure, potentially leading to instrument shutdown or false alarms. Jiwei Ring-11 tuning fork level switches are designed with sufficient thermal tolerance for internal electronics and feature insulation and heat-dissipation structures to ensure long-term stability. Their high-temperature models can withstand up to 400°C, achieving international-leading performance. Even under extreme heat, measurement accuracy and reliability are maintained, providing robust support for industrial processes under challenging conditions.

- Long-Term Reliability and Maintenance: High-temperature design not only handles transient heat but also extends equipment lifespan, reduces maintenance frequency, and minimizes failure risks, ensuring continuous production.

Through scientifically determined design temperatures, equipment maintains reliability and safety even under occasional high-temperature events, which is critical for industrial safety management and uninterrupted operations.

3. Supplier Responsibilities and Recommendations

- Base equipment selection and quotation on design temperature to ensure safety under extreme conditions.

- Clearly specify design temperature, design pressure, and reference standards in quotations for client clarity and review.

- Proactively confirm client-provided parameters; if only process temperature is available, consult engineering design documents or technical specifications.

- Offer selection options for different design temperatures, helping clients understand the necessity and risk differences of high-temperature designs.

4. Conclusion

Even if the maximum process temperature is only 80°C, design temperature serves as the safety baseline for industrial equipment selection, while process temperature is only a reference for operation. For instruments such as Jiwei Ring-11 tuning fork level switches, high-temperature conditions affect probe integrity, seal reliability, and electronic component stability, making it essential to select devices based on design temperature. Correct selection prevents years of downtime, rework, and accident risks, whereas saving costs by ignoring design temperature may result in catastrophic equipment failure under abnormal conditions.