Reactor Level Control Case Study | Jiwei Ring-11 Vibrating Fork Level Switch in Complex Reaction Conditions

1. Project Background

In fine chemicals and new materials production, reactors are not only the core vessels for reactions but also critical nodes for production safety and process stability. Level control may seem basic, yet it directly affects feeding sequence, reaction pacing, high-level interlocks, and emergency handling.

This case comes from a new materials production facility at Daya Bay Petrochemical Industrial Zone, Huizhou, Guangdong Province, China. The plant has pilot-to-production scale reactors, each with an effective volume of 3–5 m³, primarily handling polymerization and modification reactions in organic solvent systems.

As production scaled up, the reactor operation pace increased, exposing the limitations of relying on manual experience combined with level instruments of insufficient stability. The plant sought reliable point-level detection to ensure stable feeding and interlock logic, rather than merely “reference-only” measurements.

2. Process Medium and Operating Conditions

The reactor contains a multi-component reaction system rather than a single, stable liquid. The main solvents include esters and ketones, with functional powders and catalysts gradually added during feeding and reaction; some solids dissolve or undergo structural changes during the process.

Physically, the medium changes significantly over time: density fluctuates with formulation and reaction progress, viscosity increases with heating and polymerization, and gas evolution introduces bubbles and disturbances.

The reactor operates under atmospheric to slight positive pressure, with temperatures fluctuating between 60–120 °C. Stirring is continuous, subjecting the liquid to shearing and turbulence. These factors make level detection a high-interference, uncertain environment, far from ideal laboratory conditions.

3. Challenges with Previous Level Detection

Prior to the Ring-11 deployment, various level detection solutions were tested. Float switches worked initially but became coated or stuck when powders were present, causing misoperations under stirring.

Capacitive level switches performed normally at commissioning but were highly sensitive to dielectric changes. As the medium composition varied, the equivalent capacitance shifted, and setpoints no longer corresponded to fixed liquid levels, failing to provide consistent detection throughout the reaction.

Low-end vibrating fork switches also failed under strong agitation and bubble interference due to inadequate vibration tolerance and signal discrimination, resulting in unstable alarms.

These issues forced repeated manual intervention in automatic feeding and high-level interlocks. Instruments, although installed, could not reliably support safety or process control, leading operators to lose trust in the level signals.

4. Selection Challenges

The main challenge was not a single parameter but the overall adaptability of the level switch. The instrument needed to provide clear, stable point-level judgments under varying medium composition, density fluctuations, and stirring disturbances.

Detection principles should not rely on parameters sensitive to process changes (e.g., dielectric constant), and must tolerate temporary bubbles, surface waves, and splashes. Long-term exposure to organic solvents and reaction byproducts also demanded corrosion resistance and structural reliability.

Many conventional solutions that were sensitive or required frequent recalibration were excluded during the engineering evaluation.

5. Jiwei Ring-11 Vibrating Fork Level Switch Solution

After evaluation, the project selected Jiwei Ring-11 vibrating fork level switches, top-mounted via flange, with probes inserted at depths corresponding to key liquid level points for detection and interlock control.

5.1 Principle and Adaptability

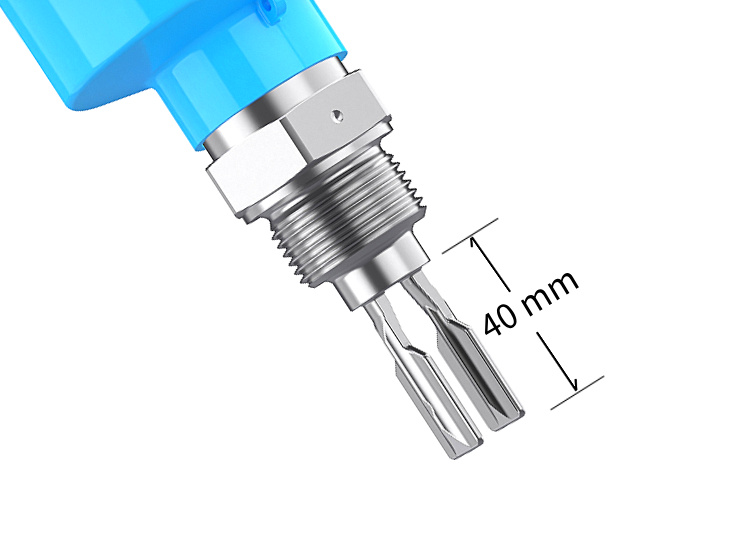

The Ring-11 uses a piezoelectric element to drive fork vibration and detect signals. In air, the fork resonates stably; when covered by liquid, damping reduces vibration frequency and amplitude. The change is captured by the piezoelectric sensor and processed by internal circuitry to output a stable switch signal, reliably indicating “material present / absent.”

Because the detection relies on mechanical vibration rather than dielectric or conductivity properties, it adapts naturally to changing medium composition and concentration, making it suitable for multi-component, organic solvent, and dynamic reaction conditions.

5.2 Anti-Disturbance Performance

The fork has high mechanical strength, enduring liquid impacts from stirring without damage. Its vibration frequency is distinct from environmental mechanical vibrations, allowing accurate level detection. It can discriminate against short-term bubbles and splashes without false triggering.

Even under high-shear stirring and gas evolution, the Ring-11 maintained stable switch status, ensuring reliable level detection and process safety.

5.3 Materials and Corrosion Protection

For organic solvent systems, contact materials include:

- 316L stainless steel

- Corrosion-resistant coatings on critical contact parts

- Hastelloy

These materials withstand esters, ketones, and byproducts, preventing mechanical failure or signal anomalies due to corrosion.

5.4 Installation and Maintenance

The instrument is top-flange mounted, with probes vertical into the reactor, avoiding direct impact from the main stirrer. Installation is simple, requiring no on-site calibration, and allows rapid commissioning. Post-installation, the switch maintains long-term reliability with minimal maintenance, suitable for continuous production and high automation.

6. Operation and Feedback

After commissioning, the Ring-11 handled critical level detection and interlocks. It triggered high-level interlocks to prevent overfeeding or overflow and provided reliable signals at lower limits for feeding or process stage transitions, maintaining operation rhythm.

Operators reported a significant reduction in false alarms and regained confidence in automatic interlocks. Reactors ran continuously and consistently to set process pacing, achieving a transformation from “level is reference-only” to “level can be fully entrusted to the instrument.” This improved operational efficiency and reduced safety risks from manual intervention, demonstrating tangible, credible results.

7. Engineering Summary

The challenge in reactor level detection lies not in instrument parameters but in:

- Understanding real operating conditions

- Matching principles with medium properties

- Designing for long-term stable operation

The Jiwei Ring-11 vibrating fork level switch proved reliable and adaptable under complex media, strong agitation, and varying physical conditions, meeting the key point-level control requirements of the reactor. For chemical users aiming to enhance process safety and automation, such stable, principle-based level switches are highly recommended over instruments relying on parameter marketing.