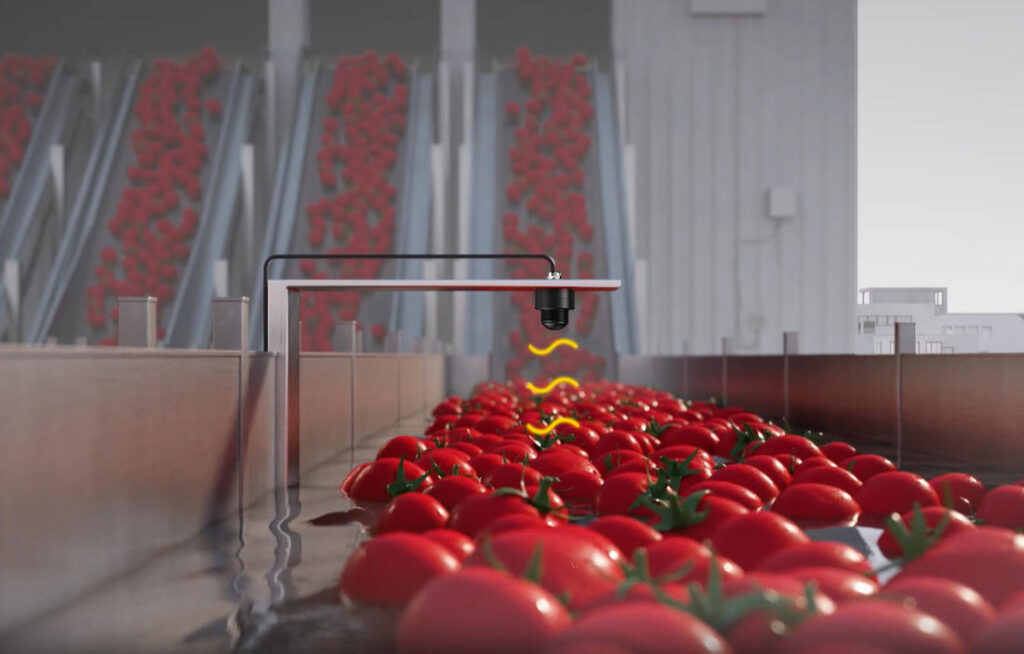

Application Case of Jiwei MINI Radar Level Meter in Tomato Washing Process

1. Process Background and Measurement Requirements

The Jiwei MINI Radar Level Meter ensures continuous and reliable liquid level monitoring in tomato washing tanks, a crucial step in the processing line before crushing, peeling, and pulping. Fresh tomatoes are typically transported in bulk by trucks and unloaded directly into large washing tanks, where a continuous water inflow creates a stable flow, conveying tomatoes to subsequent cleaning and sorting equipment.

The core goal of this process is not only to clean the tomatoes but also to maintain a continuous and stable flow under high production conditions, avoiding compression or accumulation. This places strict requirements on tank liquid level control: if the level is too low, tomatoes cannot be lifted and conveyed effectively; if too high, overflow may occur, and tomatoes may float unevenly, affecting sorting and washing quality.

Therefore, continuous, stable, and reliable level measurement of the washing tank is a fundamental prerequisite for ensuring smooth operation of the entire production line.

2. On-Site Conditions and Measurement Challenges

The tomato washing tank is not a static liquid environment. Key characteristics include:

- Continuous water flow: Inflow and outflow occur simultaneously, causing dynamic liquid surface changes.

- High-pressure air bubbling: Air bubbling is used to enhance cleaning, producing bubbles and foam on the surface.

- Mixed objects: Tomatoes, stems, floating debris, and stones or mud are present in the tank.

- High hygiene and maintenance requirements: Direct contact with the medium must be minimized; equipment should be easy to clean and low-maintenance.

3. Solution: Jiwei MINI Radar Level Meter

To address these challenges, the Jiwei MINI Radar Level Meter was selected and installed above the washing tank for continuous measurement.

Using millimeter-wave radar, the sensor emits high-frequency electromagnetic waves and calculates the distance to the liquid surface based on the returned signal, providing stable level data. The sensor is fully isolated from the medium, unaffected by tomato movement, bubbles, or water quality changes.

The compact design of the MINI series makes it suitable for installation above food processing equipment, in pipelines, or other limited spaces, easily integrating into existing washing lines without major modifications.

4. Installation and Commissioning

It is mounted on the tank’s top beam, pointing vertically at the tank center. This ensures the radar receives echoes primarily from the stable liquid area, avoiding false echoes caused by obstructions or angled installations, and provides a clear signal for processing.

The meter features a narrow 6° beam angle, concentrating radar energy and defining the measurement area. In narrow tanks with complex internal structures and uneven material distribution, the narrow beam effectively avoids sidewalls, support beams, and localized tomato accumulation, reducing false readings. Even during low liquid levels or sudden influxes of tomatoes, the meter reliably detects the real surface, ensuring continuous measurement.

During commissioning, only basic parameters need setting. The radar is insensitive to dielectric constant variations, making it suitable for water with tomatoes, bubbles, and foam, significantly shortening setup time and facilitating rapid line commissioning.

The MINI Radar Level Meter supports remote parameter optimization and software upgrades. If washing intensity, production rhythm, or tank structure changes after commissioning, engineers can remotely adjust key measurement parameters to maintain stable output under varying conditions. This improves adaptability to complex conditions without affecting production, reduces repeated on-site adjustments, and ensures long-term stable operation.

5. Operational Performance

In continuous production:

- Liquid level signals remain stable under turbulence and bubbling conditions.

- Sudden influxes of tomatoes are promptly captured.

- Foam coverage does not significantly affect readings.

Stable level data is used to adjust inflow valves and conveyor speed, ensuring even tomato distribution, preventing accumulation, and avoiding temporary shortages.

6. Customer Benefits

Safer Production:

Non-contact measurement isolates the instrument from the tank medium, avoiding hygiene risks and eliminating mechanical failures due to tangling, jamming, or wear. Accurate level signals prevent unplanned downtime, ensuring continuous, stable production.

More Stable Cleaning:

Continuous monitoring maintains optimal liquid levels for tomato lifting and distribution. High-pressure air cleaning becomes consistent, improving overall cleaning stability.

Reduced Maintenance Costs:

No moving parts in the measurement process, strong adaptability to water quality, bubbles, and debris, stable long-term performance, reducing inspections and maintenance frequency.

User-Friendly Operation:

Compact design fits above existing equipment, simple commissioning, low operational skill requirements, suitable for multi-point and batch deployment in food processing lines.

7. Application Summary

In tomato washing and conveying, liquid level measurement is crucial to cleaning quality, transport efficiency, and production stability. Measurement accuracy depends not only on hardware but also on signal processing, parameter settings, and adaptability.

The Jiwei MINI Radar Level Meter, with reliable hardware and mature software algorithms, effectively handles turbulence, bubbles, and material disturbances. Optimized echo recognition and filtering strategies ensure accurate level readings. Combined with remote parameter adjustment and software upgrade support, it provides a highly adaptable, sustainable liquid level measurement solution for the food processing industry.