Case Study: Jiwei Level switch Solve High-Temperature, High-Pressure and Highly Adhesive Media Level Detection in Fine Chemical Waste Treatment

Summary

This case study describes the automation and safety upgrade carried out at the core “three-waste” treatment center of Odom Fine Chemicals. The project adopted Jiwei’s Ring-11 vibrating level switch(for liquid only) and Tube-11 vibrating rod level switch to solve two critical challenges: high-temperature, high-pressure limit monitoring of flammable recovered solvents, and low-level detection of highly viscous wet sludge. The solution significantly enhanced system safety, operational stability, and environmental compliance.

I. Project Background

During production, the Odom plant generates large quantities of waste liquid containing flammable organic solvents and high-moisture chemical sludge. The core objective of the treatment center is to achieve solvent recycling and sludge reduction and harmless disposal.

1. Challenges of the Waste Solvent Recovery Station (Overflow Protection Required)

Waste solvents are recovered through distillation towers and stored in multiple large-capacity tanks. These solvents have the following characteristics:

- Highly flammable, classified as hazardous chemicals requiring strict explosion-proof measures

- High temperature and pressure, typically around 80 °C and 0.5 MPa

- Complex media properties, including batch-to-batch variations in density, viscosity, and dielectric constant

Such conditions demand a highly reliable high-level interlock system. When the liquid exceeds the safe limit, the inlet valve must shut off immediately, and emergency depressurization must start. However, traditional float switches have short lifespans under high temperature and pressure and are prone to jamming, making them unsuitable for safety-critical duties.

2. Challenges of the Sludge Drying Silo (Low-Level Alarm Required)

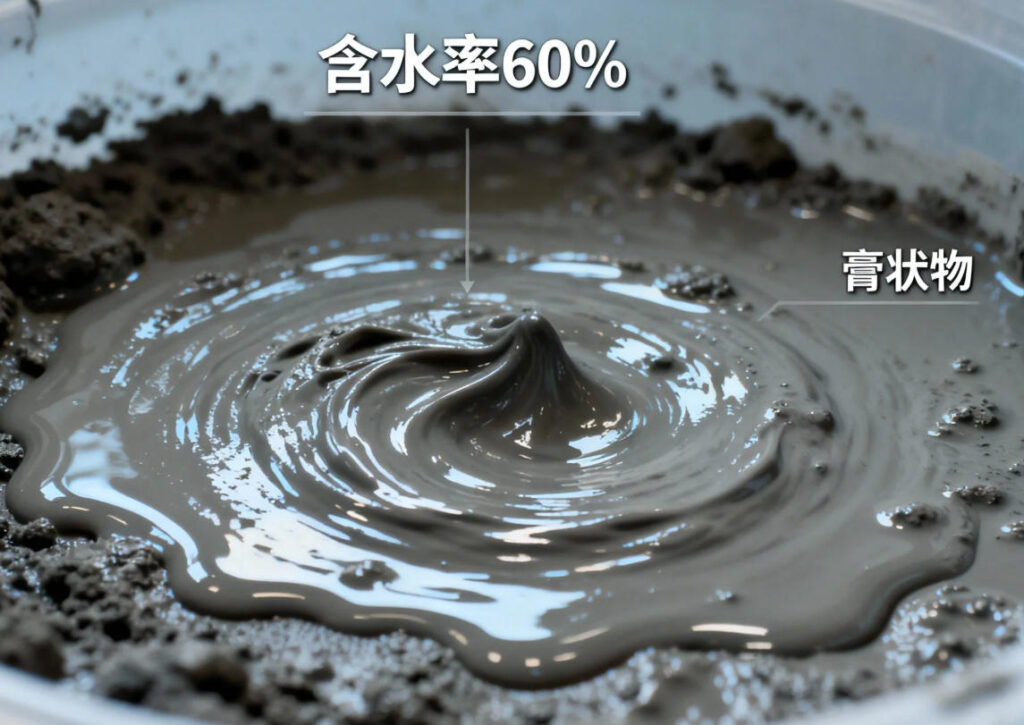

After solvent recovery, residues and precipitates are pumped into the sludge drying silo. The sludge exhibits:

- Water content up to 60%

- Strong adhesiveness, bridging tendency, and corrosiveness

The drying silo requires accurate low-level monitoring to prevent the screw conveyor from running dry and to ensure continuous feed to the dryer. Previously, capacitive switches frequently caused false alarms or failures due to heavy sludge buildup, resulting in significant maintenance workload.

II. Jiwei’s Solution

After rigorous evaluation and on-site testing, the plant selected Jiwei’s professional level switches to address both measurement challenges.

1. High-Temperature, High-Pressure Limit Protection for Solvent Tanks

(Selected Product: Jiwei Ring-11 Vibrating Level Switch)

The Ring-11 vibrating level switch was selected for its high-temperature and high-pressure capability and full explosion-proof certification. The probe (500 mm insertion length) is made of corrosion-resistant 316L stainless steel.

Operating principle:

The Ring-11 detects changes in probe vibration amplitude. When the liquid covers the probe, vibration amplitude drops sharply, triggering the output signal. This physical principle ensures highly reliable detection that is completely unaffected by dielectric constant, density, pressure, or bubbles, making it ideal for harsh solvent conditions and a superior alternative to float switches.

Safety interlock integration:

The Ring-11 provides DPDT dual-relay output directly connected to the Safety Instrumented System (SIS):

- One contact drives local audible/visual alarm

- The other triggers the SIS to shut down the upstream pump within milliseconds

This dual-layer protection ensures 100% overflow safety.

2. Low-Level Detection in the Sludge Drying Silo

(Selected Product: Jiwei Tube-11 Vibrating Rod Level Switch)

The Tube-11 vibrating rod switch features a polished probe, Jiwei’s patented dual-rod structure, and high sensitivity suitable for viscous materials. With an IP67 rating, it withstands moisture and corrosive environments.

Operating principle:

The Tube-11 uses a unique nested dual-tube design. The inner and outer tubes are tuned to the same resonant frequency. When driven by piezoelectric elements, the tubes vibrate in resonance. When viscous sludge contacts the outer tube, the resonance is disrupted and the vibration amplitude decreases. The intelligent circuit detects the change and outputs a switching signal.

This design provides:

- Excellent anti-adhesion performance

- High detection sensitivity

- Reliable operation even with severe sludge buildup

Bridging prevention:

Installed above the discharge outlet, the Tube-11 detects actual flowing material. It avoids false “material present” signals caused by bridging, a common failure mode with capacitive sensors.

With the Tube-11 in place, the maintenance interval for the sludge level switch increased from weekly to quarterly, greatly reducing labor requirements and improving the reliability of the treatment process.

III. Implementation and Benefits

1. Implementation Details

Both level switches use DN50 flange connections to ensure secure and easy installation. During commissioning, Jiwei engineers fine-tuned the Ring-11 sensitivity according to the solvent tank’s dynamic surface fluctuations, enhancing interlock reliability.

2. Economic and Safety Benefits

• Zero safety incidents

After adopting the Ring-11 for high-level interlock protection, the plant achieved zero overflow incidents in high-temperature, high-pressure solvent tanks and passed inspection by the local safety authority.

• Reduced maintenance costs

The Tube-11’s anti-adhesion design extended the cleaning cycle from weekly to quarterly, reducing annual labor costs and freeing up manpower for critical equipment maintenance.

• Improved operational efficiency

Reliable low-level detection prevents screw conveyors from running dry, reduces screw wear, and ensures stable feed to the drying furnace, maintaining environmental compliance and continuous plant operation.

IV. Conclusion

Jiwei’s Ring-11 vibrating level switch and Tube-11 vibrating rod level switch, based on physical principles unaffected by variations in medium properties, successfully solved two extreme measurement challenges common in fine chemical industries: high-temperature, high-pressure flammable liquids and highly adhesive paste-like solids. The project delivered a highly reliable, low-maintenance automated control system, elevating the safety and operational efficiency of the “three-waste” treatment center to an industry-leading level.

Jiwei level switches are an excellent alternative to VEGA for customers seeking reliable performance, fast delivery, and strong adaptability to complex process conditions. With robust designs, patented anti-buildup technology, and proven stability in applications involving high temperature, high pressure, and strongly adhesive media, Jiwei switches deliver consistent performance while maintaining a competitive cost advantage. They integrate easily into existing control systems, making them a practical and dependable replacement for VEGA in both new installations and retrofit projects.