Solving Radar Level Meter Signal Fluctuations in Complex Industrial Conditions

Causes of Radar Level Meter Signal Fluctuations

Radar level meters, known for non-contact measurement, high accuracy, and corrosion resistance, have become the preferred choice for liquid level monitoring in oil & gas, chemical, food, and metallurgical industries. However, complex industrial conditions often lead to signal fluctuations, affecting control reliability and alarm accuracy.

In industrial environments, radar signal fluctuations are commonly caused by multiple factors:

- Liquid surface disturbances: Pumps, agitators, and bubbles can create temporary waves, causing short-term measurement deviations.

- Steam interference: Rising steam from high-temperature liquids produces false echoes, reducing measurement accuracy.

- Foam layers: In food or chemical slurries, foam or emulsified surfaces scatter radar waves, causing unstable signal amplitudes.

- Dust interference: High dust concentrations in metallurgical, grain, or chemical silos scatter radar waves, generating false signals.

- Complex container structures: Internal protrusions, support beams, or piping attachments can create secondary reflections, interfering with accurate measurement.

- Dielectric constant variations: Changes in liquid temperature, concentration, or composition affect dielectric properties, leading to fluctuating radar echo strength.

Signal fluctuations can compromise real-time level control, trigger false alarms, or even cause equipment shutdowns, making solutions essential in industrial applications.

Engineering Solutions

High-Frequency Radar and Antenna Optimization

- High-frequency radar: 80 GHz FMCW radar, with short wavelength and narrow beam angle, focuses on the main echo and minimizes reflections from walls or agitators.

- Antenna design: Directional and focused antennas improve main echo detection while reducing noise interference.

- Beam focusing: Adjusting the beam toward the liquid center reduces sidewall or accessory reflections.

Intelligent Echo Recognition and Algorithm Processing

- Main echo identification: Signal amplitude, peak position, and historical data help determine the main echo.

- Digital filtering: Smooths continuous sampling data to reduce short-term liquid surface fluctuations.

- Outlier removal: Eliminates echoes caused by steam, foam, or dust for stable readings.

- Dynamic thresholding: Adjusts recognition thresholds according to different media and conditions for improved measurement reliability.

Installation Optimization

- Avoid installing antennas directly facing agitators, protrusions, or supports.

- Position antennas along the liquid centerline to reduce wall reflections.

- Use reflection suppressors or tilt antennas in long vessels or silos.

Multi-Point Sampling and Data Fusion

- Multi-point sampling combined with averaging algorithms minimizes the effect of transient surface disturbances.

- Historical data fusion and outlier removal improve continuous measurement accuracy and reduce false alarms.

Temperature and Medium Adaptation

- Temperature compensation algorithms correct deviations caused by dielectric changes.

- High-dielectric liquids such as syrups or dairy products adjust radar echo recognition automatically, ensuring stable measurements.

Advantages of Jiwei JWrada® Radar Level Meters

Jiwei JWrada® radar level meters are designed for complex industrial conditions and offer multiple technical advantages:

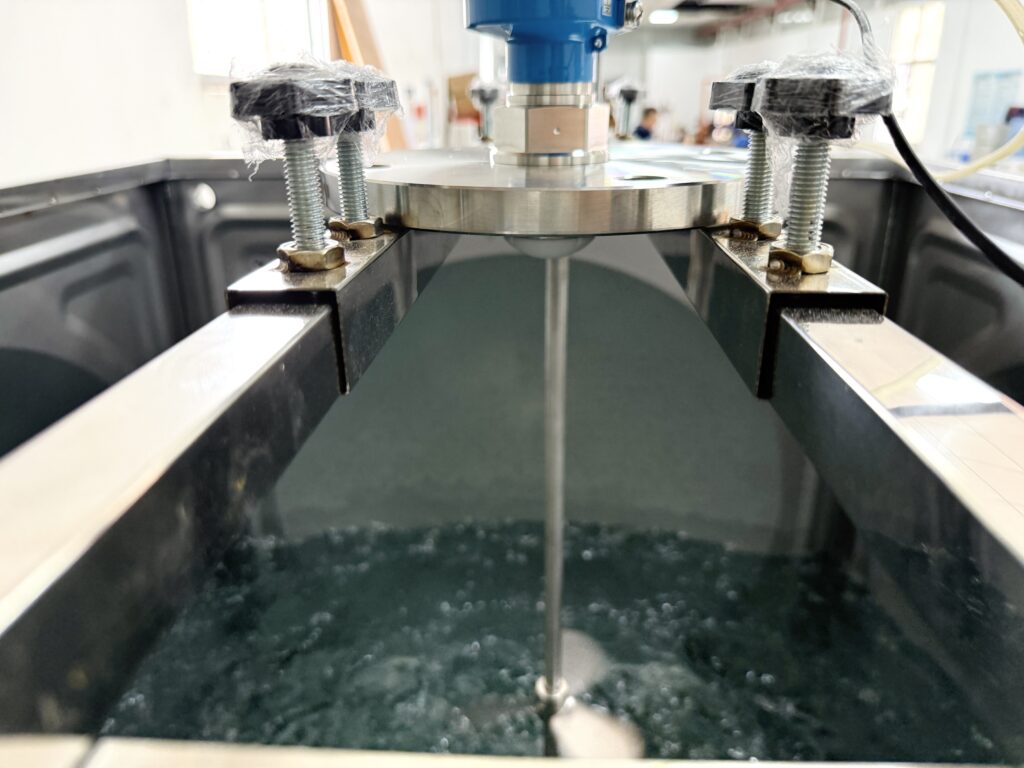

- Strong anti-agitation capability: Reliable measurements even under high-flow or stirred liquids, ensuring continuous monitoring.

- Steam and foam immunity: Accurate measurements under high-temperature steam or foam, preventing false alarms.

- Corrosion resistance: 316L stainless steel and special coatings suitable for acidic or alkaline media.

- Dust interference resistance: Stable echo detection in dusty silos and pipelines.

- High-temperature and high-pressure adaptability: Operating from -40°C to +400°C, suitable for steam tanks and metallurgical silos.

- Intelligent algorithms: Built-in echo analysis, dynamic filtering, and outlier removal provide smooth, reliable data output.

Typical Applications

Food Processing

- Scenario: Chocolate, beverage, and dairy production lines.

- Products: Ring-11 tuning fork switches + JWrada® radar level meters.

- Advantages: Compatible with CIP/SIP cleaning; continuous measurement under foam or slurry agitation; precise high/low level control and safety alarms.

Oil & Gas

- Scenario: Pipelines and storage tanks.

- Products: Ring-11 tuning fork switches + JWrada® radar level meters.

- Advantages: Replaces imported VEGA products; explosion-proof and corrosion-resistant; operating range -40°C to +220°C; ensures continuous pipeline monitoring and overflow alarms, safeguarding energy transport.

Metallurgy

- Scenario: High-temperature dusty silos and melting environments.

- Products: Tube-11 vibrating rod switches + JWrada® radar level meters.

- Advantages: Dual-probe design supports high temperature and dusty conditions; SIL2/SIL3 safety applications; stable level monitoring reduces downtime and maintenance costs.

Engineering Best Practices

- Condition assessment: Consider liquid type, temperature range, dust concentration, and steam presence when selecting the radar model and antenna type.

- Installation optimization: Avoid agitators, protrusions, and other sources of secondary reflection; adjust antenna orientation and height according to vessel design.

- Echo calibration and algorithm optimization: Adjust peak recognition, filtering, and echo processing logic to minimize fluctuations and enhance signal reliability.

- Maintenance: Keep sensors clean and free of residue or corrosion for long-term stability.

- Data monitoring: Use JWrada® intelligent algorithms and historical data to detect potential anomalies and provide early warnings, enabling smart management under complex conditions.

Conclusion

Radar level meter signal fluctuations are common in industrial environments due to liquid disturbances, steam, foam, dust, vessel structure, and dielectric changes. By combining high-frequency radar, antenna optimization, intelligent echo analysis, data fusion, and proper installation, fluctuations can be effectively minimized.

Jiwei JWrada® radar level meters leverage proprietary algorithms, anti-interference design, corrosion and dust resistance, and high-temperature tolerance to deliver stable and reliable level measurement under stirring, steam, corrosive, and dusty conditions. Widely applied across oil & gas, food, and metallurgy sectors, JWrada® provides safe, efficient, and accurate solutions for complex industrial liquid level measurement.