Reliable Level Monitoring of Calcium Sulfate Silos with Jiwei Vibrating Rod Level Switch in Xinjiang

1. Project Background

Vibrating rod level switch ensures precise and reliable level monitoring in calcium sulfate silo production and storage of calcium sulfate at a chemical plant in Xinjiang. Calcium sulfate is a high-density, easily compacted, and sticky powder, and the silos are exposed to high dust, humidity, temperature fluctuations, and local pressure variations—conditions that challenge traditional level measurement devices.

The plant operates multiple silos with capacities exceeding 50 tons. Continuous feeding is required for production, packaging, and transport. Challenges included:

- Traditional devices failure: Float switches often stick, and guided wave radar devices produce false or drifting signals in dusty, sticky conditions.

- Frequent manual inspections: High dust levels pose health and explosion risks, making inspections labor-intensive and dangerous.

- Production risks: Unstable level monitoring can lead to overfilling, uneven feeding, or downtime, impacting production continuity and safety.

To address these challenges, the plant required a high-reliability, low-maintenance, continuous level measurement solution capable of handling high dust, humidity, and variable particle size while monitoring high, middle, and low levels automatically.

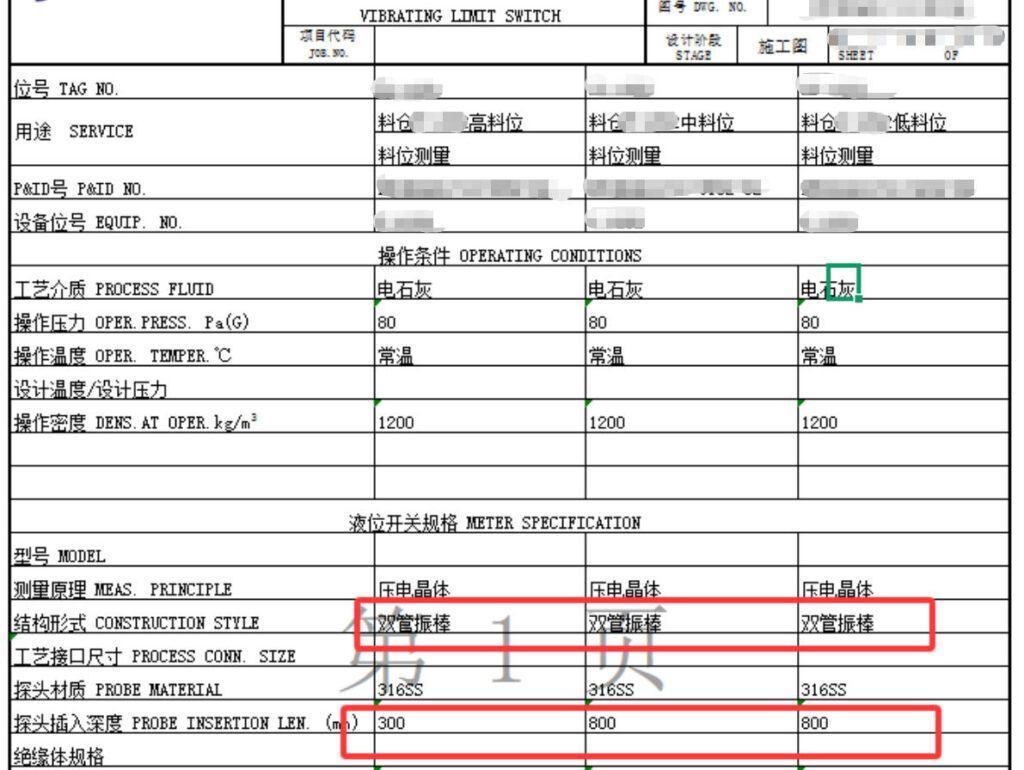

During technical evaluation, the customer specifically requested dual-rod vibrating level switches. Compared to single-rod designs, dual rods provide better vibration stability and anti-adhesion performance. This ensures accurate detection even under powder accumulation, vibration, or uneven settling, preventing false alarms at high, middle, or low levels.

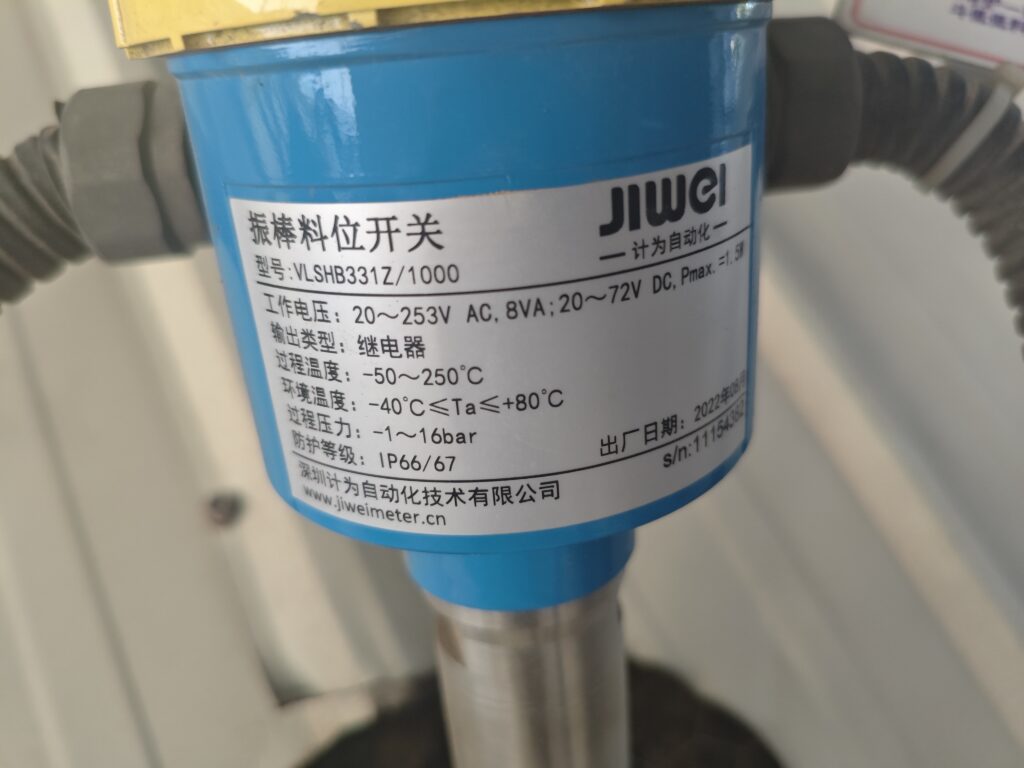

After evaluation, the plant selected Jiwei vibrating rod level switches to monitor high, middle, and low levels in the silos, achieving continuous, stable, and low-maintenance operation. Jiwei, a leading Chinese level switch manufacturer with multiple national patents, offered a robust solution suitable for the harsh powder environment.

2. Technical Selection Reasons

2.1 Dual-Rod Structure for Anti-Adhesion and Dust Resistance

Jiwei vibrating rod level switches use a dual-rod structure driven by piezoelectric crystals. When powder covers the rods, vibration stops, triggering a switch signal. This design effectively avoids float sticking and signal drift in dense powder and high humidity environments.

2.2 Corrosion-Resistant Stainless Steel

Probes and rods are made of 316L stainless steel, resistant to chemical corrosion and mechanical wear. FKM/PTFE dual seals ensure long-term reliability under high dust, humidity, and temperature variations.

2.3 Protection and Explosion Resistance

The device offers IP66/IP67 protection, handling dust accumulation and high-pressure cleaning, while meeting both gas and dust explosion protection standards:

- Flameproof (Ex db): Ex db IIC T1…T6 Gb / Ex tb IIIC T80℃…T440℃ Db

- Intrinsic Safety (Ex ia): Ex ia II CT1…T6 Ga / Ex ia IIIC T₂₀₀100℃…T₂₀₀450℃ Da

This dual protection ensures safe operation in high-dust silos and environments with potential combustible gas.

2.4 Flexible Interfaces and Installation

Jiwei switches support multiple standard interfaces for flexible installation, including Chinese standard , ANSI/ASME (US), JIS (Japan), and DIN/EN (Europe). This allows high, middle, and low level monitoring with alarms or pump protection signals, adapting to different silo designs and industrial standards.

2.5 High Reliability and Low Maintenance

With a simple structure and patented dual-rod design, Jiwei vibrating switches have 5–8 years longer service life than typical alternatives. Minimal maintenance is needed, reducing downtime and labor costs.

3. Installation Environment and Solution

3.1 Installation Positions

- High level: Top of silo, preventing overflow and protecting feed equipment.

- Middle level: Sidewall, controlling feed pump and ensuring automated production.

- Low level: Bottom, preventing pump dry running and ensuring continuous feeding.

Positions were verified through CFD simulation and field experience to avoid dust accumulation and turbulence.

3.2 Interface and Sealing

Sealing uses FKM/PTFE dual seals. Pre-installation checks and low-pressure leak tests ensure long-term reliability under powder and moisture exposure.

3.3 Electrical Connection and Output

Output: SPDT dry contacts, 24V DC 5A, integrated with PLC/DCS for automated alarms, pump control, and interlocks. Signals were tested for stability, confirming reliable operation.

4. Conclusion

Jiwei vibrating rod level switches in Xinjiang calcium sulfate silos demonstrate exceptional performance in complex powder environments. Dual-rod design with 316L stainless steel and durable seals ensures stable level signals, avoiding adhesion, clogging, and false triggers.

IP66/IP67 protection and dual explosion-proof design (Ex db / Ex ia) guarantee safe operation in high dust and complex environments, achieving long-term, low-maintenance monitoring.

Real-time level monitoring combined with alarm and interlock functions improves production continuity and safety. Multi-standard interfaces (China, US, Japan, Europe) allow flexible installation.

This case proves that Jiwei vibrating rod level switches provide a reliable, low-maintenance, and highly adaptable solution for continuous powder level measurement in calcium sulfate silos, supporting intelligent, visual, and safe silo management.