Smart Tank Level Measurement: Jiwei’s Intelligent Solutions

In modern industrial production, storage tanks are more than simple containers—they are critical nodes connecting raw material storage, process control, and final product output. From chemical liquids, battery electrolytes, and alcohol fermentation liquids to powders and granular materials, accurate, reliable, and sustainable level measurement is essential to ensure production continuity, safety, and efficiency. In the era of smart manufacturing, Smart Tank Level Measurement is no longer just a matter of sensor accuracy; it is a systematic engineering solution that encompasses measurement principles, interference immunity, signal communication, process safety, and long-term consistency.

Shenzhen Jiwei Automations Ltd. has long been focused on level measurement, offering radar level meters, vibrating rod level switches, rotary paddle level switches, tuning fork liquid level switches, and magnetic float level indicators. With rich engineering experience, Jiwei ensures stable, long-term, and traceable monitoring in complex operating conditions. This article introduces the core aspects of smart tank level measurement from an engineering perspective and highlights how Jiwei products achieve reliable and stable measurement in practice.

1. Level Measurement is Moving Towards Intelligence

Traditional level measurement focused primarily on single-point accuracy or instrument specifications. However, in smart factories, tank monitoring faces new requirements:

Stability over single-point accuracy

Process fluctuations, electromagnetic interference, and temperature changes often have a greater impact than the nominal accuracy of instruments.

Interference immunity as a key metric

Industries such as chemical plants, battery workshops, and food production lines feature numerous VFDs and motor starts that generate EMI/EMC interference.

Long-term consistency

Instruments may operate continuously for tens of thousands of hours, requiring minimal drift, low degradation, and durable structures.

Intelligent diagnostic capabilities

Including echo quality assessment, status monitoring, self-diagnostic outputs, and standardized communication protocols (Modbus, HART).

Complex media adaptability

Multiphase interfaces, foam, agitation, vapor, dust, high viscosity, and low dielectric constant all present measurement challenges.

Jiwei’s diverse level products are designed around these systematic requirements, providing more than simply “detecting the liquid level.”

2. Jiwei Radar Level Meters: Core of Smart Tank Measurement

Radar level meters are the mainstream solution for liquid measurement. Jiwei radar level meters use 80 GHz high-frequency FMCW technology, offering focused beam control and high echo signal-to-noise ratios, ensuring stable operation even in narrow tanks, stirred tanks, or steam and condensation environments.

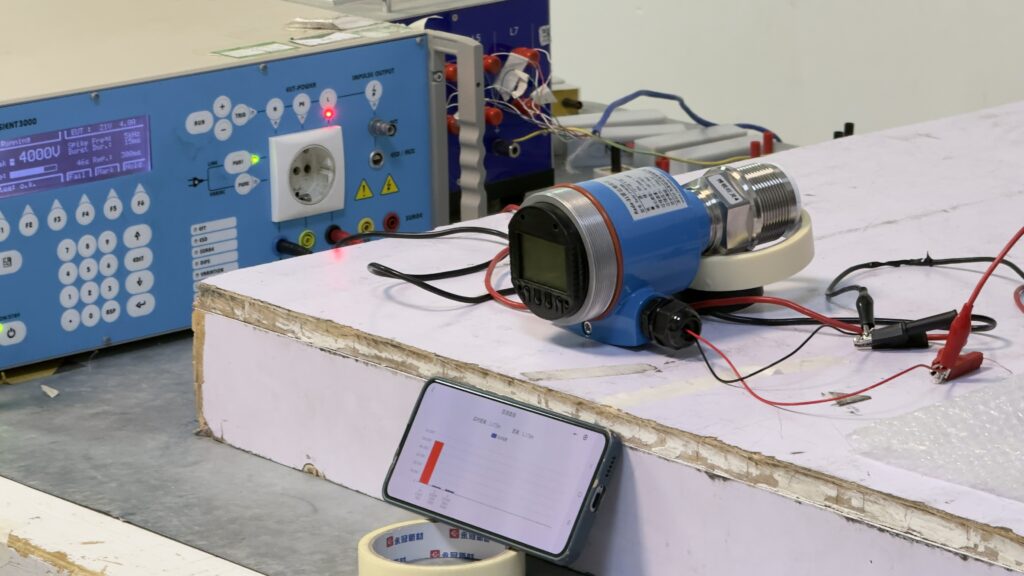

EMC design ensures measurement stability

Radar level measurement relies on receiving extremely weak echo signals, making instrument reliability highly dependent on EMC (electromagnetic compatibility) design. Jiwei radar meters undergo systematic EMC verification before leaving the factory to ensure long-term stable operation in complex electromagnetic environments. Tests cover radiation immunity, conduction immunity, electrostatic discharge (ESD), electrical fast transients (EFT), power surges, and RF field injection, simulating various interference sources that may occur on site.

The EMC evaluation assesses not only the whole device’s immunity but also power filtering, antenna shielding, grounding, and front-end RF chain interference margin. This full-chain EMC optimization ensures radar echo signals are accurately detected in high-interference environments, maintaining continuous and stable level measurement. Engineering experience shows that high-level EMC design is more critical than nominal specifications for on-site reliability, making it the core factor for long-term radar performance.

Complex process adaptability

Jiwei radar level meters have proven reliable in a variety of challenging applications across multiple industries:

- High-temperature tanks – withstanding thermal stress on electronics and antenna materials while maintaining stable echo acquisition.

- Fermentation tanks with foam and agitation – advanced signal processing suppresses paddle and foam interference for continuous, accurate measurement.

- Low dielectric constant liquids (electrolytes, alcohols) – optimized antenna design and front-end circuitry ensure stable echoes in weak-signal media.

- Strong EMI environments in battery workshops – robust EMC design resists noise from VFDs and motor starts, maintaining continuous and reliable output.

- Powder silos – horn antenna options allow accurate detection of material surfaces even in high dust concentrations or complex shapes.

- Corrosive media – PTFE-coated antennas provide excellent chemical resistance while maintaining non-contact measurement, reducing maintenance and operational risk.

With non-contact measurement, corrosion resistance, and maintenance-free operation, Jiwei radar is the preferred solution in chemical, battery materials, new energy, and food processing industries, enhancing reliability and reducing operational costs and safety risks.

Intelligent features

Jiwei PRO and MINI series radar meters support:

- Real-time echo curve diagnostics to monitor liquid level trends.

- False level identification to eliminate errors from foam, debris, or transient disturbances.

- Valve and agitator interference suppression to stabilize readings during process operations.

- Standard communication protocols (Modbus, 4–20 mA, HART) for integration with PLC or DCS systems.

- Automatic focusing, filtering, and measurement optimization algorithms to enhance echo recognition in complex media.

- Jiwei SmartControl® Bluetooth app, allowing mobile access to real-time level data, echo curves, alarms, and device health for convenient remote monitoring and operation.

These capabilities enable engineers to monitor tanks precisely, implement intelligent control and early warning, simplify maintenance, and improve process safety and operational efficiency.

3. Solid Material Silos: Level Switches Remain Essential

Although radar is suitable for most liquids and some solids, powders and granular materials still require level switches.

Spin-11 Rotary Paddle Level Switch

- Suitable for powders and granular materials.

- High-torque motor, resistant to dust impact.

- Sealed bearing design ensures durability.

- Ideal for carbon black, flour, feed, sand, etc.

- Mechanical actuation ensures reliable high/low level control.

Tube-11 Vibrating Rod Level Switch

- Suitable for light powders, low-density powders, suspended solids, and free-flowing materials.

- Designed for large silos and high-temperature processes (up to 400°C).

- Resistant to mechanical vibration and material buildup.

- Applicable in feed, mining, and chemical industries.

Ring-11 Tuning Fork Liquid Level Switch

- High reliability, low maintenance.

- Suitable for high/low liquid level detection in foamy or mixed liquids.

- Applicable to emulsions, oils, caustics, process water, long tanks up to 6 meters, marine tanks, LNG/LPG storage.

- Certified with SIL, 3C, EAC, CE, EX, etc.

- Excellent immunity to bubble-induced false triggering, widely used in food, brewery, chemical plants, and marine sewage tanks.

4. Smart Tank System Safety: Beyond Measurement

The core goal of smart tank level monitoring is to ensure system-level safety and production efficiency. Jiwei level switches play a key role in overflow, dry-run, and material loss prevention. Measurement failures can lead to chemical leaks, agitator dry-running, pump cavitation, high-temperature equipment hazards, or dust-related safety issues. Reliable level switches are thus not just instruments—they are critical components of production safety.

Data visualization and system integration

Integration with upper-level systems via Modbus or HART enables:

- Historical trend tracking

- Remote diagnostics

- Tank network monitoring

- Inventory forecasting

- Process optimization

These functions meet the real-world requirements of smart factories for precise tank monitoring and process control.

Reducing total lifecycle cost

Reliable level measurement minimizes downtime, false alarms, manual inspection, and material loss, improving production efficiency and long-term cost savings. Experience shows these savings far exceed the price difference of individual instruments, reflecting the true value of systematic smart tank monitoring.

5. Conclusion: Engineering Stability as Core Value

Smart tank level measurement is not about high data specifications but whether devices can operate reliably, stably, and fault-free in complex, interference-rich industrial environments.

Jiwei’s value lies in both hardware excellence and systematic engineering with intelligent software optimization, including:

- Maintainable, diagnosable, and traceable smart capabilities, combined with proprietary algorithms to optimize measurement accuracy and interference suppression.

- Wide operating adaptability, from -60°C to 450°C, with industry-specific customization options.

- Complete EMC design, ensuring radar and level switches remain stable in complex industrial environments.

- Deep understanding of various media, enabling precise measurement of liquids, slurries, and powders.

- Extensive industrial experience, ensuring suitability across chemical, battery materials, food processing, and new energy sectors.

- Structural reliability and long-term consistency, supporting long-term operation with minimal drift and low maintenance.

Through hardware-software synergy, Jiwei provides not just level measurement instruments but a complete, dependable smart tank monitoring solution. Smart tank level measurement is a systematic engineering endeavor, and Jiwei continues to deliver professional products and engineering expertise to ensure reliable level monitoring for chemical, energy, food, battery, and environmental protection industries.