Ring-11 Ultra-high Temperature Fork Level Switch

Shenzhen Jiwei Automations Ltd. developed the Ring-11 Ultra-High Temperature Tuning Fork Level Switch with advanced cooling, enabling stable operation above 280°C and up to 400°C. This innovation fills a domestic gap and provides a reliable alternative to imported high-temperature level measurement devices.

In response to the extremely demanding process conditions exceeding 280°C, Shenzhen Jiwei Automations Ltd. has successfully pioneered the development of the Ring-11 Ultra-High Temperature Tuning Fork Level Switch equipped with advanced water and air cooling technologies, building upon the foundation of the original Ring-11 model. This groundbreaking product is capable of maintaining long-term stable operation in harsh environments with temperatures soaring up to 400°C, effectively filling a critical domestic technological void in ultra-high temperature level measurement and control. It stands as a powerful solution poised to supplant imported counterparts in key industrial applications.

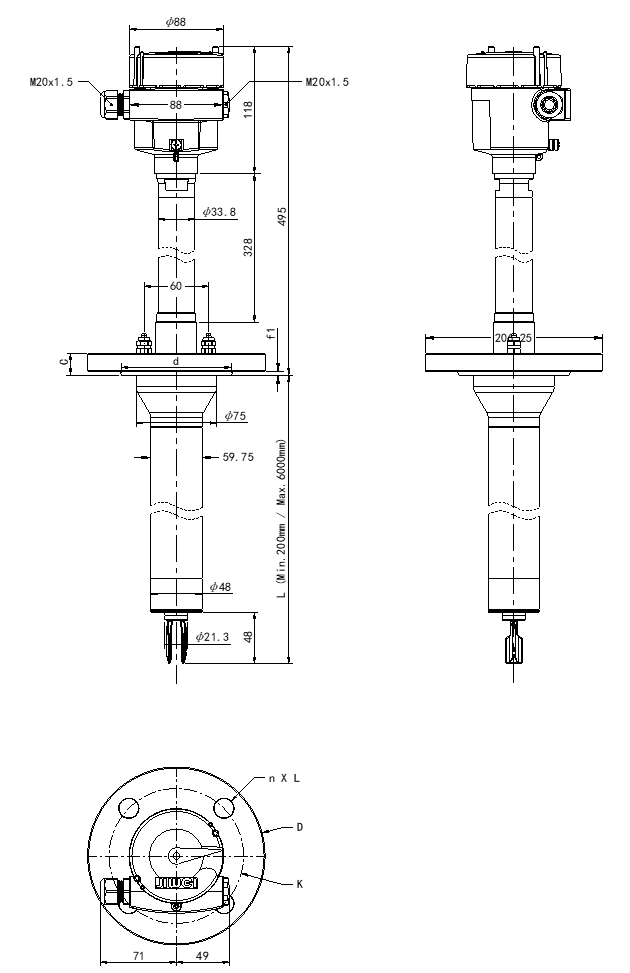

The operating principle of the Jiwei Ring-11 Ultra-High Temperature Tuning Fork Level Switch is identical to that of the conventional Ring-11. Building upon the original high-temperature design, this product innovatively incorporates an additional cooling sleeve structure to ensure reliable measurement under ultra-high temperature conditions.

One end of the cooling sleeve is welded and fixed to the process flange, with inlet and outlet ports for cooling medium (gas or water). The other end connects to the vibrating probe. Cooling medium is delivered through a capillary copper tube directly to the tuning fork vibration area, effectively reducing the probe temperature.

This design keeps the operating temperature of the piezoelectric ceramic element and wiring within permissible limits, guaranteeing long-term, stable, and reliable level measurement even at temperatures up to 400°C.

● Ultra-high temperature resistance, up to 400°C: Innovative water/air cooling design effectively protects internal components, ensuring long-term stable operation in extreme temperatures and breaking industry limits.

● Compact design for tight spaces: With a fork length of only 40mm, ideal for installation in pipelines and confined areas, enhancing on-site adaptability.

● Supports low-density liquids: Precisely tuned to measure liquids with densities as low as 0.5 g/cm³, meeting diverse light liquid level control needs.

● Excellent anti-interference performance: Effectively resists foam, bubbles, viscous materials, and vibration to ensure stable and reliable signals.

● Multiple output options for strong system compatibility: Relay, two-wire, NAMUR, and transistor outputs for easy integration into various industrial control systems.

● Certified by multiple authorities: Holds SIL2/3 functional safety certification (verified on CNCA website), CE, 3C, EAC and explosion-proof (intrinsic safety and flameproof) approvals for safe use under harsh conditions.

● Meets food and pharmaceutical standards: Compliant with HACCP, 3A, and other hygiene regulations, suitable for industries requiring high cleanliness.

● Frequency variation detection principle for high stability: Uses frequency shift to determine level status, ensuring reliable operation with low maintenance in continuous monitoring applications.

| Applicable liquid | Density | ≥0.5g/cm³ |

| Viscosity | 0.1~10000mPa.s① | |

| Flow velocity | Max. 6m/s | |

| Probe data | Surface finish | Ra<0.5μm② |

| Vibration frequency | ~1200Hz | |

| Fork length | 40mm | |

| Accuracy | Measurement error | ±1mm |

| Delay | 2mm | |

| Repeatability | 0.1mm | |

| Switching delay | When immersed | 0.5s |

| When laid bare | 1s | |

| Power supply③ | Relay | 20~253V AC/20~72V DC |

| Two-wire | 10~36V DC | |

| NAMUR | 8.2V DC | |

| Transistor | 6~48V DC | |

| Max. power consumption | 8VA(AC);1.5W(DC) | |

| Output | Relay | 5A/253V AC/24V DC |

| Two-wire | 8mA/16mA,Alarm<2.3mA | |

| NAMUR | ≤1mA or ≥2.1mA, Fault ≤1mA | |

| Transistor | NPN/PNP | |

| Installation conditions④ | Process pressure | -1~64bar |

| Process temperature | Regular temperature: -50~150℃ | |

| High temperature: -50~280℃ | ||

| Ultra-high temperature: -50~400℃⑤ | ||

| Ambient temperature | -40~70℃ | |

| Storage and transport temperature | -40~80℃ | |

| Overvoltage protection | Relay | Category III, class I |

| Two-wire | Category III, class II | |

| Certificates and approvals | SIL Qualification⑥ | SIL2 (HFT=0) / SIL3 (HFT=1) |

| Explosion-Proof | Intrinsic Safety: Ex ia IIC T1…T6 Ga | |

| Flameproof Enclosure: Ex db IIC T6…T1 Gb | ||

| Gas/Dust Explosion-proof: Ex db IIC T6…T1 Gb + Ex tb ⅢC T440℃…T80℃ Db | ||

| CE | LVD and EMC Certificates | |

| Ingress Protection | IP66/IP67 | |

| Materials | Housing | Aluminum alloy, stainless steel |

| Ground terminal | 316L | |

| Thread connection | 316L | |

| Flange connection | 316L, 316L coated Enamel, ECTFE, PFA | |

| Fork | 316L, 316L coated Enamel, ECTFE, PFA | |

| Process seal | Klingersil C-4400 |

Note:

① Assume the medium density equals to 1.

② Applicable: for Hygienic Ring-11 only.

③ The voltage of explosion-proof models can be executed according to the technical requirements on the Explosion-proof Certificate.

④ The relationship between the process temperature, medium temperature and ambient temperature of explosion-proof models can be executed according to the technical requirements on the Explosion-proof Certificate.

⑤ Designed with water cooling for ultra-high temperature applications.

⑥ Comply with international standard IEC61508 (national standard GB/T20438).

● Petrochemical Industry

For liquid level monitoring in high-temp tanks, cracking units, and reactors. Ring-11 operates reliably at 400°C, ensuring safe control of high-temp, high-pressure, volatile liquids.

● Chemical & Fine Chemicals

Suitable for acidic, corrosive, or high-boiling liquids like organic solvents. Cooling design ensures continuous, reliable signals under prolonged heat.

● Thermal Power & Energy

Used in heat transfer oil tanks, condensate tanks, and boiler feedwater systems to optimize energy efficiency and prevent dry-run or overflow.

● Environmental & Waste Incineration

Stable level monitoring for high-temp leachate collection and waste heat boiler cooling water systems, enhancing safety.

● Metallurgy & Steel

Works in casting cooling water, high-temp lubricants, and dust removal tanks, maintaining accuracy amid heat and electromagnetic interference.

● Building Materials & Cement

Applied in preheater washing, kiln tail drainage, and high-temp additive tanks, delivering stable control above 300°C.

● New Energy

Used in lithium battery electrolyte tanks and solvent recovery systems, ensuring safe control of flammable high-temp liquids.