Vibrating Level Switch Coatings: Enamel, ECTFE, PFA Selection & Engineering Guide

(Shenzhen Jiwei Automations Ltd · Technical Article)

In industrial sites, the types of media that come into direct contact with level switches are extremely diverse, ranging from common water and oils to strong acids and bases, high-salinity solutions, and high-temperature media. Each type of medium can cause different degrees of corrosion, wear, swelling, or deposition on the probe surface. To ensure reliable operation and stable measurement over the long term, the corrosion-resistant treatment of wetted materials becomes a core aspect of level switch design.

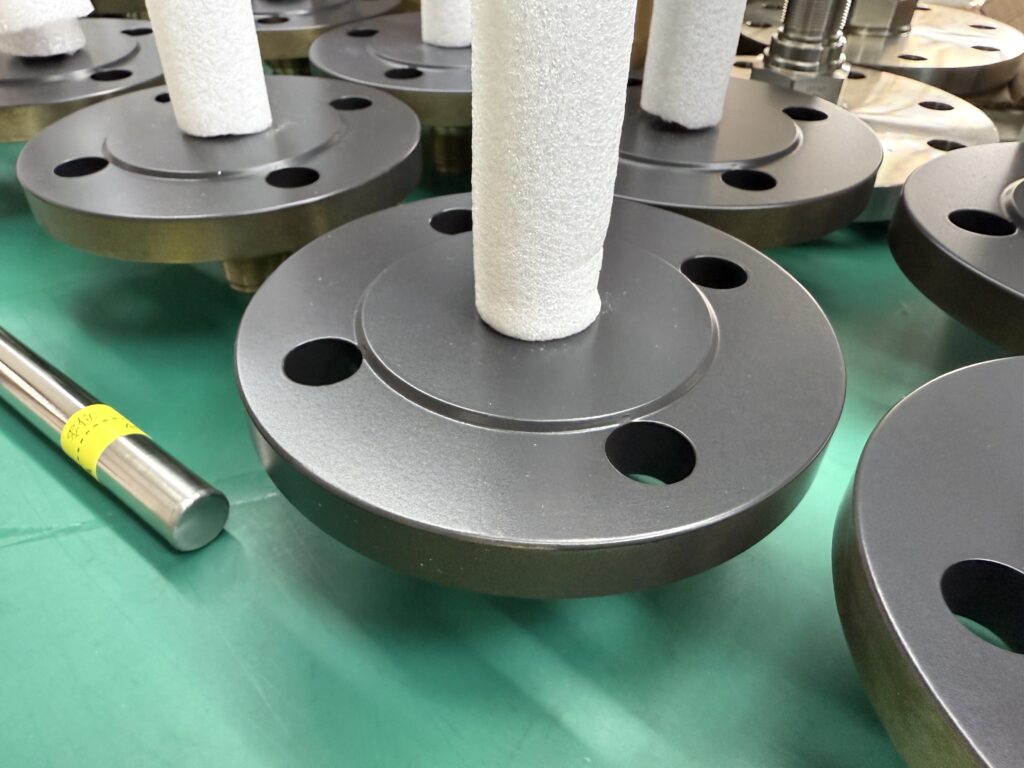

Shenzhen Jiwei Automations Ltd provides three typical protective coatings for vibrating level switches (represented by the Ring-11 series) according to different working conditions: Enamel, ECTFE, and PFA. These coatings differ in composition and structure, resulting in significant differences in corrosion resistance, temperature tolerance, mechanical strength, and manufacturing complexity, allowing adaptation to a wide range of field requirements.

This article presents a systematic engineering perspective on the material characteristics, sintering temperature, corrosion resistance, temperature range, and recommended usage of these three coatings under specific working conditions.

1. Enamel Coating: Traditional High-Corrosion Protection via High-Temperature Sintering

Enamel coating is applied on the metal surface using inorganic glaze and then sintered at temperatures above 800°C, forming a continuous, dense, glass-like protective layer. It is one of the most mature and stable industrial corrosion protection processes, especially suitable for severe acidic environments. Thanks to its high hardness and glassy structure, enamel remains inert under high temperature and strong corrosion for long periods, but its brittleness makes it more suitable for stable environments rather than applications with frequent mechanical impacts.

Characteristics and Performance

- Dense glass-like structure, non-adsorptive and impermeable

- Excellent resistance to strong acids such as sulfuric and hydrochloric acid

- High hardness and wear resistance

- Anti-aging, does not powder or degrade over time

Engineering Advantages

- Stable and reliable in high-temperature, highly corrosive environments

- Long service life

- Suitable for systems requiring minimal contamination risk

Engineering Limitations

- Brittle, not suitable for impact or vibration-prone conditions

- High-temperature sintering requires precise control, increasing manufacturing cost

- Not suitable for small or complex-shaped components

Recommended Applications

- Strong acidic media (H₂SO₄, HCl, etc.)

- High-temperature and stable corrosive environments

- Systems with strict cleanliness requirements, such as food and pharmaceuticals

2. ECTFE Coating: Balanced Performance and Cost-Effective Fluoropolymer

ECTFE is a copolymer of ethylene and chlorotrifluoroethylene within the Teflon family. With excellent corrosion resistance, good mechanical properties, and moderate processing temperatures, it has become the most common “general-purpose” protective coating in industrial instrumentation. Compared with enamel, ECTFE is more flexible and less likely to crack under minor impact, while being more cost-effective than PFA, making it an ideal engineering choice for many chemical plants.

Characteristics and Performance

- Sintering temperature around 250–270°C, stable processing

- Good resistance to acids, bases, salt spray, and humidity

- High mechanical strength, crack-resistant

- Suitable for most corrosion environments from room temperature to medium temperature

Engineering Advantages

- Balanced performance, compatible with a wide range of media

- Lower cost, suitable for large-scale use

- Impact-resistant and less prone to cracking than enamel

- Mature process with controllable delivery cycles

Engineering Limitations

- Continuous temperature limit ~150°C

- Performance is limited under combined high-temperature and highly corrosive conditions

- Chemical inertness not as high as PFA

Recommended Applications

- Room or medium-temperature acidic or alkaline media

- Salt spray, humid, or outdoor environments

- Chemical, environmental, and food industry systems with stable loads

- Cost-sensitive applications requiring reliable corrosion protection

3. PFA Coating: Premium Protection for Extreme Corrosion Conditions

PFA is one of the highest-performance fluoropolymers, combining the corrosion resistance of PTFE with the processability of FEP. It represents the “top-tier” of protective coatings for level instruments. Its extremely high chemical inertness ensures minimal reaction with industrial media, maintaining long-term stability even in high-temperature, highly corrosive, and frequently cleaned environments. PFA is the preferred choice for critical processes and key equipment.

Characteristics and Performance

- Sintering temperature: 380–400°C

- Continuous operating temperature up to 260°C

- Extremely chemically inert, compatible with almost all chemicals

- Very low surface energy, resists buildup and fouling

- High toughness, resistant to thermal shock and mechanical stress

Engineering Advantages

- Can withstand high temperature and strong corrosion simultaneously

- Long service life and extremely high reliability

- Non-stick properties reduce adhesion of viscous liquids, easy maintenance

- Stable under frequent steam cleaning (CIP/SIP)

Engineering Limitations

- Highest cost

- High processing difficulty, requiring strict structural design support

- Sintering of thin-walled structures is challenging

Recommended Applications

- High-temperature, strong acidic, or highly corrosive media

- Resins, colloids, viscous liquids

- Food and pharmaceutical industries with steam cleaning

- Critical control points and high-reliability equipment

4. Typical Application Comparison of Three Coatings (Engineering Selection Reference)

| Working Condition | Recommended Coating | Reasoning |

|---|---|---|

| High-temperature strong acid | Enamel / PFA | High corrosion and temperature resistance |

| Room-temperature acids and bases | ECTFE | Best cost-performance, stable corrosion resistance |

| High temperature + strong corrosion | PFA | Maintains stability under heat |

| Mechanical impact | ECTFE / PFA | Avoids enamel brittleness |

| High viscosity / sticky media | PFA | Low surface energy, prevents adhesion |

| Food / pharmaceutical | PFA / Enamel | Chemically inert, prevents contamination |

5. Jiwei’s Coating Technology Practice

Shenzhen Jiwei Automations Ltd has established a complete and mature engineering system for wetted materials of vibrating level switches through long-term field applications. The system covers the full process from working condition assessment to coating design and validation, including:

Multi-round working condition evaluation

The engineering team evaluates media composition, concentration variations, temperature range, flow velocity, and impact load in multiple rounds, ensuring long-term stable operation of each vibrating probe. For complex conditions, special process media simulations are conducted to identify potential corrosion or wear risks in advance.

Coating thickness control and sintering process optimization

By precisely controlling coating thickness, uniformity, and high-temperature sintering parameters, the adhesion between coating and probe substrate is maximized, improving chemical resistance, wear resistance, and long-term reliability. Multiple process optimization plans are established for different materials and media to ensure consistent product performance.

Vibrating probe stress distribution design enhancement

The probe structure design fully considers the brittleness of coatings and vibrational dynamics. Stress distribution optimization and local reinforcement reduce the risk of microcracks from vibration or impact, extending product service life.

Accelerated corrosion testing of multiple coatings

A complete laboratory system for accelerated corrosion testing of Enamel, ECTFE, and PTFE coatings is established. Extreme conditions including high concentration, strong corrosion, and high temperature are simulated to ensure long-term reliability of selected solutions in real applications.

With more than 15 years of deep application experience in chemical, environmental, food, and energy industries, Shenzhen Jiwei Automations Ltd has developed a mature and stable engineering selection guide for wetted materials of vibrating level switches. This system ensures product durability and safety under complex conditions, demonstrating the company’s technical strength and engineering practice capabilities in level measurement.

6. Conclusion

The corrosion resistance of level switches depends not only on the base material but also on coating chemical resistance, temperature tolerance, mechanical strength, and manufacturing processes. For different working conditions, coatings can be selected as follows:

- Enamel: strongest corrosion and high-temperature resistance, but brittle

- ECTFE: balanced performance, suitable for most room-temperature corrosion conditions, the mainstream industrial choice

- PFA: top-tier performance, capable of handling the harshest high-temperature and corrosive environments

By scientifically selecting the appropriate coating, vibrating level switches achieve significantly improved reliability and service life in complex media, providing long-term, stable process safety for industrial plants.