Radar Level Transmitters vs Traditional Level Instruments

The Importance of Reliable Level Measurement in Industrial Processes

In chemical, petrochemical, food processing, and other high-safety industrial sectors, accurate level measurement is a core part of production operations. Level monitoring directly affects process safety, operational efficiency, and economic performance.

Traditional level instruments—such as float level gauges, ultrasonic level transmitters, and differential pressure (DP) transmitters—have a long history of use but often struggle in high-temperature, highly corrosive, or foam/dust-laden environments. These conditions lead to measurement instability, frequent maintenance, or instrument failure, increasing downtime and operational costs.

In contrast, non-contact radar level transmitters leverage advanced radar technology to deliver high-precision, stable, and maintenance-free level measurements, meeting modern industrial demands for safety, efficiency, and smart process control.

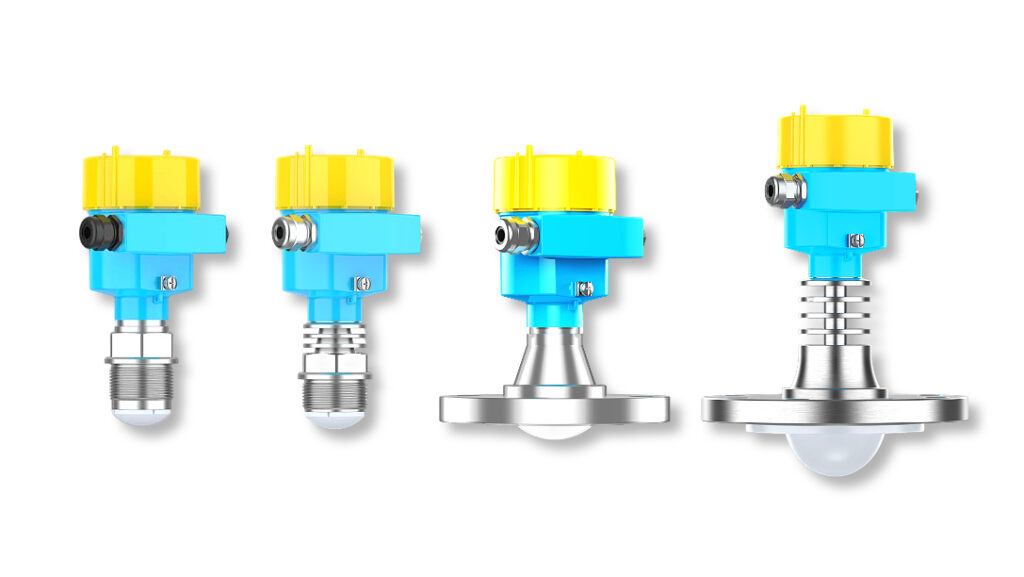

Non-Contact Radar Level Transmitters: High-Precision, Stable, Maintenance-Free Solutions

Limitations of Traditional Level Instruments

Float Level Gauges

Float sensors detect liquid levels via mechanical or magnetic coupling. While simple and low-cost, they are only suitable for clean liquids. In corrosive or viscous media, floats and seals wear quickly, causing mechanical friction and bearing degradation that reduce measurement accuracy.

Ultrasonic Level Transmitters

Ultrasonic sensors measure liquid surfaces using reflected sound waves. Non-contact in principle, they are affected by vapor, foam, or acidic mist. High temperatures also reduce signal stability, making measurements unreliable in harsh environments.

Differential Pressure Transmitters

DP transmitters measure level via liquid hydrostatic pressure. While suitable for closed vessels, they are sensitive to sediment buildup, blockages, and corrosion, requiring frequent cleaning and calibration.

Common Issues with Traditional Instruments:

- Measurement accuracy fluctuates under changing process conditions

- Frequent maintenance and high downtime

- Poor adaptability to high-temperature, high-corrosion, or foaming environments

Authority Reference: According to NAMUR NE 43, traditional level instruments have limited long-term reliability under highly corrosive, high-temperature, or dusty conditions (NAMUR, 2019).

Technical Advantages of Non-Contact Radar Level Transmitters

Non-contact radar level transmitters use high-frequency microwave signals to measure liquid levels, eliminating mechanical wear and blockage issues. FMCW (Frequency Modulated Continuous Wave) or pulsed radar can penetrate foam, vapor, and dust to provide stable, continuous readings.

Corrosion Resistance and Long-Term Reliability

Jiwei radar level transmitters feature PFA lining and 316L stainless steel with PTFE or PFA protective layers, providing robust resistance against strong acids, bases, and viscous liquids. This material combination extends service life, reduces maintenance frequency, and minimizes downtime costs compared to conventional instruments.

High-Temperature Adaptability

Traditional instruments often fail above 150 °C, whereas Jiwei radar operates reliably from -40 °C to +220 °C, suitable for high-temperature alkylation units, acid tanks, and other complex environments. Even with rapid liquid surface fluctuations, measurement accuracy remains stable.

Intelligent, Maintenance-Free Operation

Non-contact design eliminates mechanical wear and clogging. Additional features include:

- HART, Modbus RTU, and Profibus PA protocol support for seamless automation integration

- Built-in Bluetooth® (v5.4) for wireless configuration and commissioning via mobile devices

- Remote monitoring and intelligent diagnostics for real-time level data and alarms

Technical Reference: FMCW radar provides high-resolution, low-noise measurement, enhancing level control accuracy (ISA White Paper, 2020).

Comparison Table: Traditional Instruments vs Radar Level Transmitters

| Feature | Float | Ultrasonic | Differential Pressure | Radar Level Transmitter |

|---|---|---|---|---|

| Non-Contact Measurement | ✗ | ✔ | ✗ | ✔ |

| High-Temperature Capability | ✗ | △ | △ | ✔ |

| Corrosion Resistance | △ | △ | ✗ | ✔ |

| Foam/Vapor Interference | ✗ | ✗ | △ | ✔ |

| Maintenance Requirement | High | Medium | High | Low |

| Functional Safety Support | Limited | Limited | △ | ✔ |

Legend:

✔ – Clear advantage, suitable for harsh conditions

△ – Moderate performance, condition-dependent

✗ – Limited applicability

As shown, radar level transmitters excel in high temperature, corrosion resistance, foam/vapor interference, and low maintenance, making them ideal for chemical, petrochemical, and high-safety industrial applications.

Safety and Standard Compliance

In hazardous areas, level measurement safety is critical. Jiwei radar level transmitters are fully Ex-certified for safe operation in flammable and explosive environments. They comply with API 2350 overfill protection standards, minimizing the risk of tank overflow.

The combination of non-contact measurement, optimized materials, and intelligent diagnostics aligns with functional safety principles, offering reliable performance for critical applications. ISO 9001 certification ensures consistent production quality and supply reliability.

Real-World Applications

Jiwei radar level transmitters have been successfully applied in high-temperature acid tanks, dusty silos, and food-grade liquid tanks.

Example 1: Alkylation unit acid tank

- Operating temperature: 180 °C (design up to 220 °C)

- Measurement range: 0–4 m

- Continuous three-year operation demonstrated:

- Stable, accurate level readings

- Zero maintenance requirements

- Significant reduction in downtime

- Lower total cost of ownership (TCO)

Example 2: Dusty material silo

- Radar penetrates dust layers, avoiding measurement errors caused by accumulation

- Traditional floats and ultrasonic sensors require frequent cleaning or fail to provide reliable readings

Operator and Economic Benefits

With radar level transmitters, operators gain:

- Reduced daily maintenance and inspection workload

- Intuitive, user-friendly interface for quick setup

- Smart alarms and remote monitoring, enhancing safety

- Extended equipment life and minimized downtime

Economically, radar level transmitters lower maintenance costs, reduce downtime, and improve production safety and efficiency, delivering higher ROI than traditional instruments—especially in high-temperature, corrosive, or complex environments.

Conclusion and Call to Action

Non-contact radar level transmitters provide unmatched advantages in complex industrial processes: corrosion resistance, high-temperature adaptability, intelligent operation, and precise measurement. Compared to float, ultrasonic, or differential pressure instruments, they reduce maintenance, extend equipment life, improve safety, and simplify operations.

👉 Action: Contact Jiwei today for a customized radar level transmitter solution and achieve safe, efficient, and reliable level control.