How Tube-11 Vibrating Rod Level Switch Solves Critical Detection Challenges in Hazardous Fireworks Powder Applications

1. Introduction: Transformation and Challenges in the Global Fireworks Manufacturing Hubs

Vibrating Rod Level Switch in Fireworks Industry: The global fireworks industry, concentrated in major production hubs across Asia, increasingly relies on vibrating rod level switches to ensure safe and reliable powder detection. These switches are critical as manufacturers transition from labor-intensive manual production to automated processes under stricter safety and labor cost pressures.

In this transformation, “human–machine isolation” and “operator–powder separation” have become strict principles. At the core of future automation is real-time and reliable material detection—especially in the most hazardous stages such as powder mixing, feeding, and charging. Achieving safe and accurate level monitoring in these environments has long been a bottleneck restricting industry-wide upgrades.

2. Harsh Operating Conditions and Measurement Difficulties

The raw materials used in fireworks impose extreme challenges on level-measurement instruments. Manufacturers must monitor oxidizers (e.g., potassium perchlorate, barium nitrate), reducers (e.g., sulfur, charcoal powder), and various metal powders (e.g., flake Al-Mg alloys, titanium). Their unique physical and chemical properties create several measurement pain points:

2.1 Ultra-Low Density & High Adhesion (Critical Challenge)

Many specialty powders—especially modified metal fuels used for specific sound or visual effects—have extremely low bulk densities, in some cases below 0.08 g/cm³. These powders are feather-light and prone to electrostatic adhesion.

Failures of conventional instruments:

Early-generation tuning-fork switches often produced false positives due to powder “bridging” or sticking between the fork tines, or false negatives due to insufficient sensitivity. This could result in undetected overfill, material overflow, or dangerous powder clouds.

Safety impact:

If level detection fails in automatic mixers or charging hoppers, excessive powder can accumulate or equipment may run dry and overheat—both direct triggers of severe fire or explosion accidents.

2.2 Combined Gas and Dust Explosion Zones

Some production steps involve organic solvents such as ethanol or acetone, creating a mixture of flammable vapors (Zone 1/2) and explosive conductive dust (Zone 21/22).

Certification challenge:

Instruments must achieve high-grade gas explosion protection (Ex d ia IIC T6) and dust explosion protection (Ex tD A21). Both mechanisms must remain safe even under extreme failure scenarios.

2.3 Cost Pressure and the Need for Reliable Alternatives

For years, major manufacturers relied on high-end international products such as VEGAVIB 61 due to their excellent sensitivity for low-density powders.

Practical difficulty:

Long procurement cycles and costs several times higher than premium local equipment became a major constraint in large-scale automation projects requiring hundreds of detection points. The industry urgently needs a solution that matches the performance of top imported products while offering shorter lead times and more manageable investment.

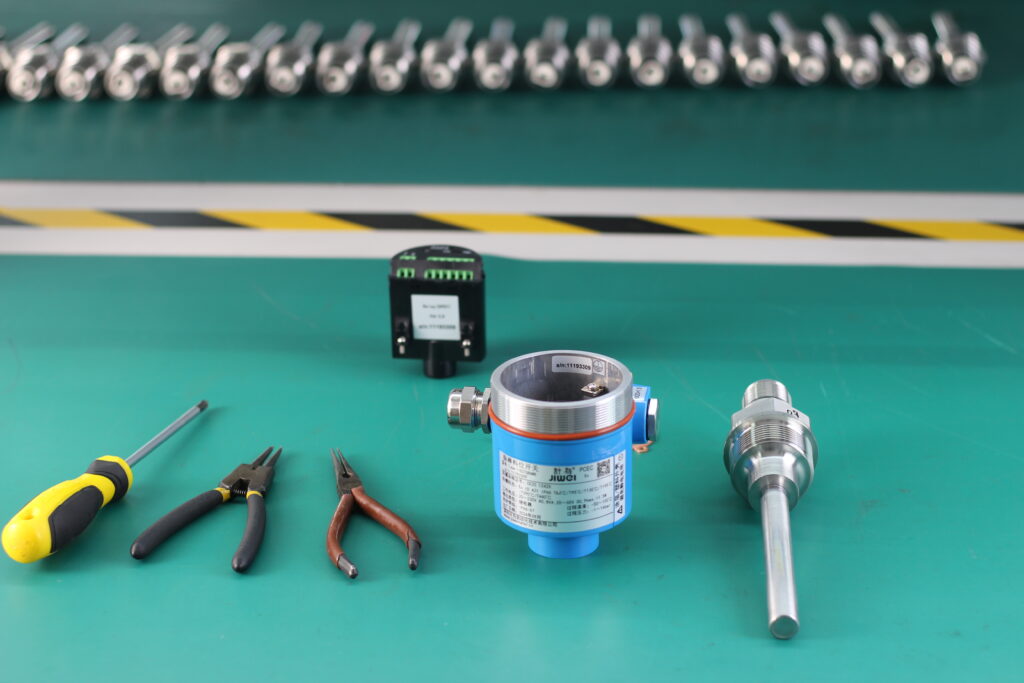

3. Technical Breakthrough: Tube-11 Vibrating Rod Level Switch

After more than one year of side-by-side testing in a leading fireworks manufacturer’s automated production lines, the JIWEI Tube-11 has proven itself as a true equivalent replacement for VEGAVIB 61—both in sensitivity and long-term reliability.

Its performance is driven by several targeted innovations:

3.1 Dual-Rod Vibrating Technology Detects Powders Down to 0.02 g/cm³

Unlike tuning forks that are prone to clogging, Tube-11 adopts a coaxial dual-rod design similar to high-end imported models.

Working principle:

A high-performance piezoelectric element excites the probe at a resonant frequency. Even extremely light powders cause a slight damping effect when they touch the rod, resulting in measurable changes in amplitude and frequency.

Tube-11’s precision-tuned electronics capture these minute changes, enabling reliable detection of powders as light as 0.02 g/cm³.

Anti-adhesion design:

Special probe coatings and structural design minimize electrostatic buildup, preventing false triggers when measuring metal powder fuels, oxidizers, and other difficult materials.

3.2 Patented “True Dual Explosion-Protection” Structure

This is Tube-11’s core competitive advantage. Its unique sealing and electrical-isolation design—protected by national patents—provides simultaneous gas- and dust-explosion protection suitable for powder-solvent hybrid environments.

It has passed the highest levels of both gas and conductive-dust explosion-proof testing, offering genuine dual-layer safety assurance.

3.3 Recognized by National-Level Industrial Safety Projects

The technology behind Tube-11 has received government-supported R&D funding due to its importance in improving safety for hazardous-material processing industries—a strong validation of its innovation and reliability.

4. Market Validation: From Pilot Trials to Industry Standard

Tube-11 Demonstrates Exceptional Stability in Highly Explosive Powder Applications

4.1 Multi-year repeat orders from leading manufacturers

During initial pilot deployment, Tube-11 units were installed at the most hazardous locations—automatic powder-mixing machine inlets and finished-product buffer hoppers—running directly “back-to-back” with VEGAVIB 61.

Results:

Tube-11 matched the imported model in both sensitivity and stability.

Long-term performance:

Over the following five years, the customer purchased several hundred units, gradually replacing older devices and designating Tube-11 as the standard for new production lines.

Customer feedback:

“Tube-11 has delivered near-zero failures and extremely low maintenance for years. We trust it completely.”

4.2 Rapid adoption across major production clusters

Word-of-mouth spread quickly in the closely connected pyrotechnics industry. Tube-11 is now widely used in key production regions across Asia.

Industry impact:

Tube-11 has become a preferred solution for detecting ultra-light oxidizers and metallic powders in many large-scale manufacturing groups.

Cost advantage:

Compared with full adoption of imported vibrating-rod level switches, replacing them with Tube-11 has helped manufacturers save hundreds of thousands of dollars while greatly shortening lead times—from months to just days.

5. Conclusion

In an industry where safety tolerances are extremely low and working conditions are uniquely challenging, the Tube-11 vibrating rod level switch has established itself as a top-tier solution. With its ability to detect powders as light as 0.02 g/cm³, its patented dual explosion-protection design, and years of proven stability in major global production hubs, Tube-11 delivers performance comparable to high-end international products—at a significantly more competitive cost.

For fireworks and pyrotechnic manufacturers seeking a reliable, safety-certified, and cost-efficient alternative to the VEGAVIB 61, Tube-11 is a robust and future-ready choice for achieving true process safety and automation upgrades.