Jiwei Fork-11 Tuning Fork Level Switch | VEGA Replacement for Foam Processing

Industry Background

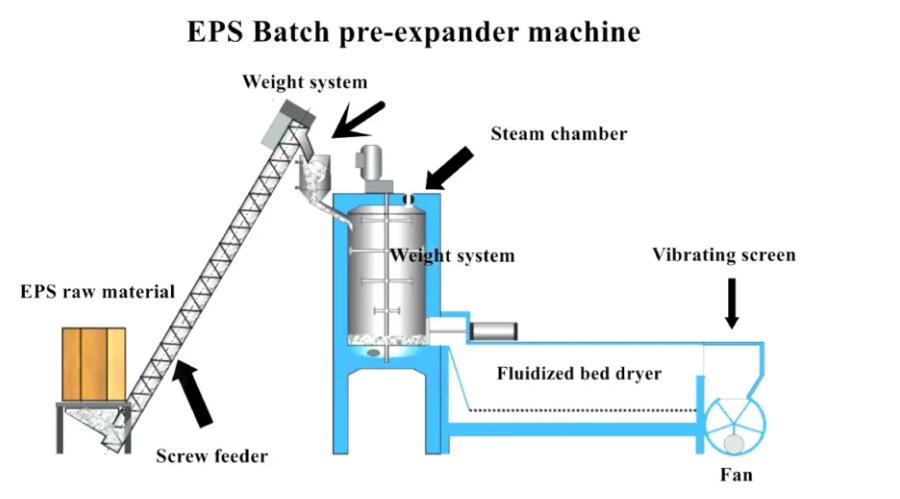

Vibrating fork level switches are widely used in the foam industry, where, whether it is the EPS pre-expansion process or light foam molding processes such as EPP and EPE, level monitoring is always a core factor determining production line stability. The typical characteristics of the foam industry are ultra-low density, uneven particle size distribution, high air content, and fluctuating flowability. Any measurement method sensitive to the medium’s density may result in false triggering, lag, or incorrect full/empty detection. Especially for pre-expanded light particles, their density can drop to as low as 0.008 g/cm³, which is close to the buoyancy limit of air, representing extremely light, fluidized particles. Under such special conditions, the ability to reliably and repeatedly detect full or empty levels is critical for maintaining both production capacity and product quality.

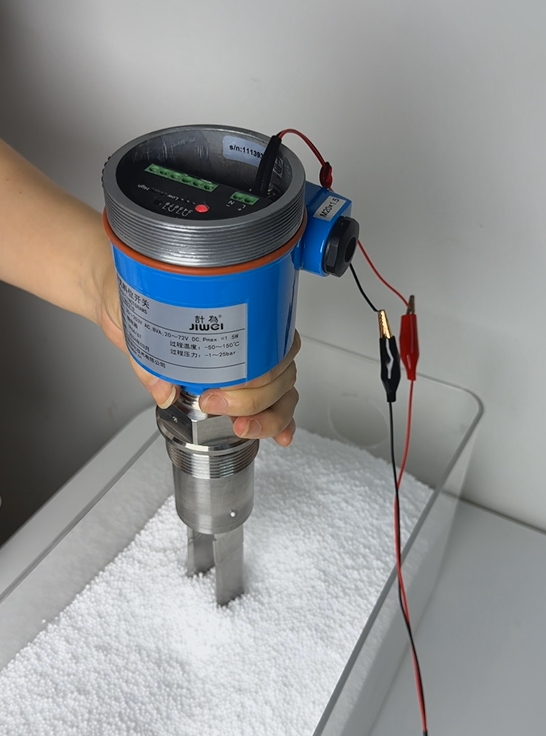

Over the past decade, one of the widely used foreign brands in the industry has been VEGA’s tuning fork level switch, which performs well in conventional powders and liquids. However, in ultra-low-density foam particles, VEGA, while usable, faces limitations in trigger sensitivity, long-term stability, and coupling with light particles, making many manufacturers feel that its measurement capability is near the limit. Particularly under conditions below 0.01 g/cm³, feedback often indicates insufficient sensitivity, installation angle dependency, and interference from low-density particles. Jiwei Automation’s Fork-11 tuning fork level switch emerged to address these extreme challenges: it can reliably trigger at 0.008 g/cm³ ultra-low-density particles and has successfully replaced VEGA in numerous pre-expander and molding machines, becoming a preferred solution for many long-term customers.

Requirements for Level Switches in Pre-Expansion Machines

The foam pre-expansion industry demands highly precise level switches due to the unique structure of pre-expansion machines. These machines typically include stirring, steam treatment, and drying functions, where the medium is not static but in a semi-fluidized, lightweight suspended state. Particles move up and down with air flow, and density distribution constantly changes. Traditional mechanical level switches cannot adapt, as they require a certain mass of material to trigger deflection. Capacitive level meters are sensitive to dielectric constants, and foam particles’ dielectric properties are close to air, making accurate detection difficult. Radar solutions are feasible in certain conditions but are costly, require high maintenance, and have limited measurement points, making simple switch-type detection preferable.

Among the various solutions, tuning fork switches appear most suitable. However, their effective operation depends on a core parameter: the medium’s damping effect on fork vibration. For ultra-low-density foam particles, this damping is minimal. The tuning fork requires very high sensitivity to detect tiny amplitude changes to achieve reliable triggering. The Fork-11 excels due to its optimized vibration structure and driving circuit, maintaining stable detection even for extremely light particles.

Characteristics of 0.008 g/cm³ Foam Particles

Many engineers underestimate the challenge of foam particles at 0.008 g/cm³. Industrial powders typically have densities of 0.2–1.0 g/cm³, while foam particles at 0.008 are only a fraction of that. Even a gentle human breath can significantly disturb these particles. They exist between solids and gases—neither possessing the mass of conventional powders nor the stable coupling of liquids—posing extreme challenges to any measurement technology relying on material properties. Consequently, stable level detection methods were lacking until the Fork-11 enabled reliable control for many manufacturers.

Level Monitoring Requirements for Molding Machines

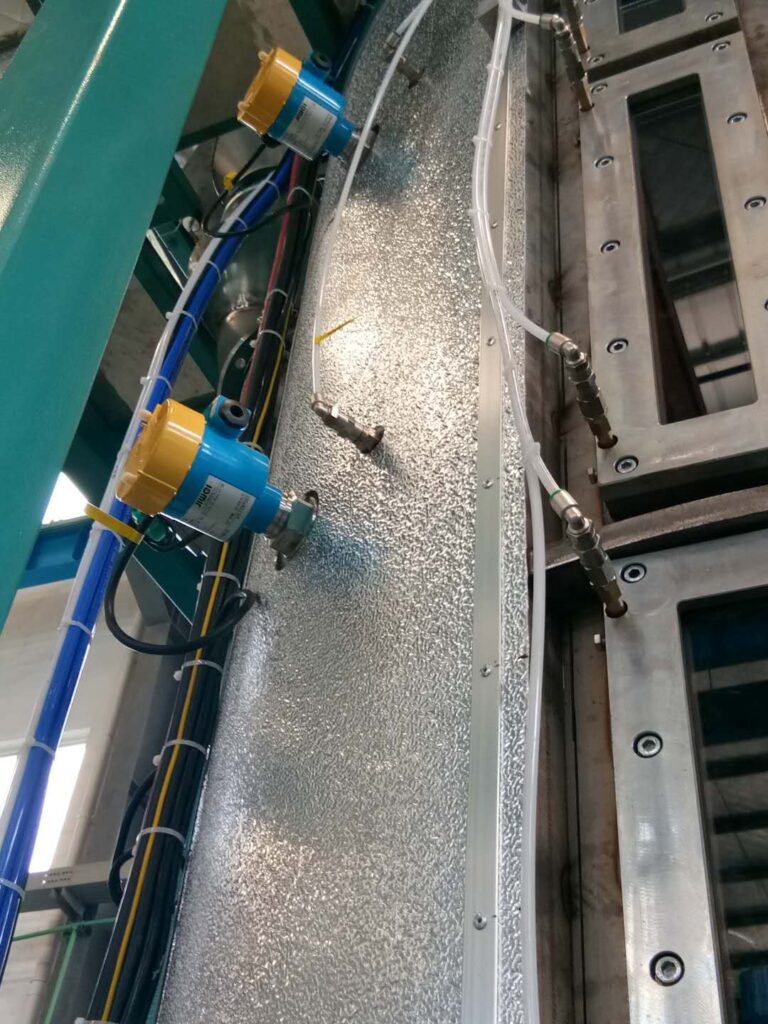

In foam molding, level monitoring presents different requirements. Molding machine hoppers are often more complex, with multiple feed and exhaust ports and connections to the molding cavity. Level switches must not only detect set heights accurately but also resist air flow disturbances, prevent interference from particle adhesion, and maintain stable operation under continuous high temperature and humidity cycles. VEGA is usable in these conditions, but its tuning window and installation angle are sensitive to light foam particles, often requiring repeated adjustments. In contrast, Jiwei’s Fork-11 can generally be used out of the box, saving downtime for adjustments and reducing production losses due to false triggers.

Ten Years of Transition: From VEGA to Jiwei

Over the past decade, more and more foam equipment manufacturers have shifted from VEGA to Jiwei Fork-11, largely due to Jiwei’s reliable supply chain and consistent product quality. The foam industry typically involves large-scale, continuous production, where downtime is costly. Therefore, manufacturers prefer solutions with short lead times, easy maintenance, reasonable pricing, and proven technical reliability. Fork-11 not only performs better in low-density conditions but has also demonstrated long-term durability, stability, and resistance to process variations. Many long-term clients report continuous repurchase over ten years, specifying Fork-11 in new equipment, expansion lines, and overseas projects, making it their standard configuration.

Why Fork-11 Can Reliably Trigger at 0.008 g/cm³

Fork-11’s recognition in the industry is not due to a single excellent parameter but to comprehensive engineering adaptability. Pre-expansion lines need stable detection of full levels to prevent overfilling, foam agglomeration, or blockage; and empty levels to ensure timely feeding, avoid dry running, and maintain pre-expansion quality. In molding, multiple point-level monitoring ensures stable cavity filling and consistent product density. Fork-11 provides reliable switch signals across these scenarios, enabling clearer production rhythms, improved product consistency, reduced material waste, and increased overall throughput.

Comparison with Peer Products

Similar products include Germany’s VEGA, Taiwan’s FineTek, and Germany’s UWT. Compared to Jiwei’s Fork-11, they show:

- Minimum triggering density: Fork-11 reliably triggers at 0.008 g/cm³; VEGA can operate in this range but at much higher cost.

- Installation flexibility: Fork-11 adapts to angles and positions; FineTek and UWT have limited sensitivity for lightweight particles.

- Maintenance cost: Fork-11 requires minimal maintenance; international brands often need periodic servicing.

- Supply and cost: Fork-11 is available in large quantities with rapid service response and competitive pricing.

Reasons for Continuous Repurchase over Ten Years

Fork-11 demonstrates long-term stability, reliably operating under steam, airflow, and humid-heat conditions without false triggers, ensuring continuous production. Its cost-effectiveness and supply reliability reduce operational expenses, and its engineering adaptability allows multi-point installation in pre-expansion and molding machines without additional modifications. Out-of-the-box usability eliminates repeated calibration, lowering downtime risk and maintenance costs.

Additionally, Fork-11 serves as a preferred replacement for VEGA, directly substituting VEGA products without adjusting installation or control logic, reducing engineering risks and costs. These advantages make Fork-11 the first choice for level monitoring in the foam industry, gaining customer trust and continuous repurchase over the long term.