Accurate Solid Sediment Interface Measurement in Industrial Wastewater Treatment with Jiwei Tube-11 & Fork-11

In industrial automation, wastewater treatment is an essential process that requires both effective removal of cations and anions and reliable interface measurement of liquids and solids to ensure stable operation, environmental compliance, and water reuse.

Common treatment methods include:

- Physical methods: sedimentation, flotation, filtration, ion exchange, etc.

- Chemical methods: Fenton oxidation, acid-base neutralization, catalytic oxidation, etc.

- Biological methods: activated sludge, biofilm processes, oxidation ponds, land treatment, etc.

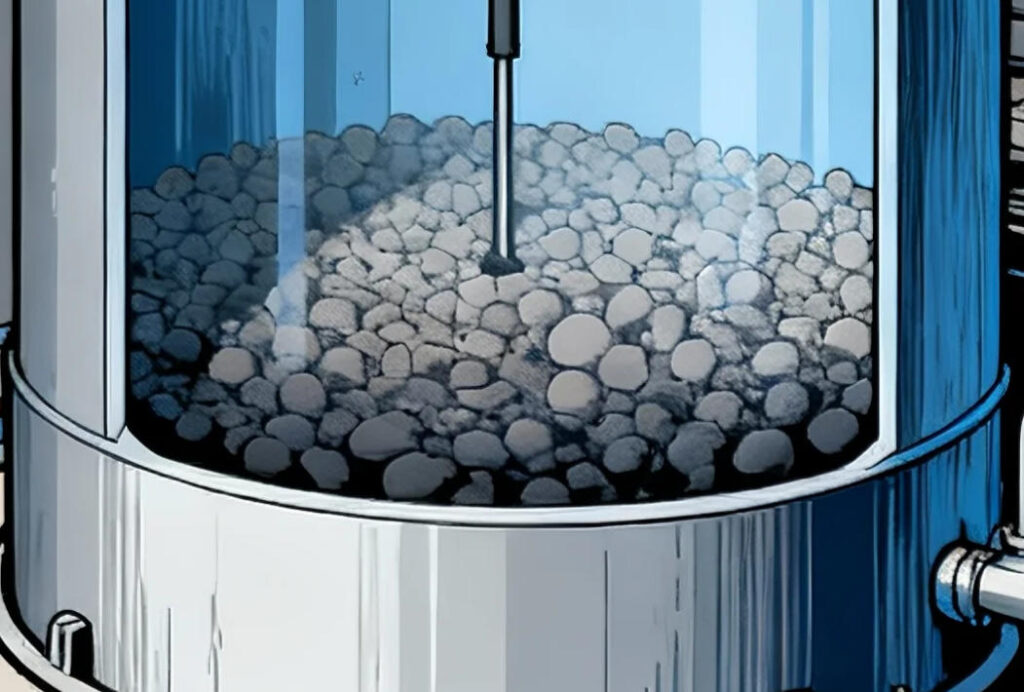

In water systems of industrial facilities, such as power plants, ion exchange is often used for resin regeneration. Sediments accumulate in the regeneration tanks, and when they reach a certain level, they must be conveyed to the next process. At this stage, an instrument capable of accurately detecting the solid-liquid interface and outputting alarm signals to trigger valves or other actuators is required to achieve automated production.

Challenges in Liquid-Solid Interface Measurement

While liquid-liquid interface measurement solutions (e.g., float level meters, magnetic level gauges) are relatively mature, measuring interfaces between liquids and solids remains a technical challenge. Many users rely on high-end imported instruments, which are costly and sometimes unreliable.

In wastewater treatment, sedimentation tanks, or sludge control systems, inaccurate detection of solid interfaces can lead to overflow, scraper malfunctions, or automated process failures, significantly affecting production efficiency and equipment safety.

Jiwei Tube-11 Vibrating Rod Level Switch Solution

Jiwei Automations’ engineers conducted in-depth research on on-site conditions and, after extensive testing and innovation, developed the Tube-11 series vibrating rod level switch over a decade ago. This product is specifically designed to measure the interface of solids in liquids.

Product Principles and Advantages:

- Dual-tube design with precise tuning: Accurate measurement of solid sediment interfaces in liquids via resonant frequency adjustment.

- High reliability: Patented technology ensures superior stability and longevity compared to conventional products.

- Automation-ready: Can be linked with discharge valves or other actuators for fully automated production.

- Wide applicability: Suitable for measuring sediments, sludge, or particulate matter in liquid media.

Application Cases in Sedimentation Tanks

Tube-11 has been successfully applied in multiple domestic water utilities and wastewater treatment plants, particularly in regeneration tanks and sedimentation pools. For example, in a large municipal wastewater treatment plant, sediments and organic particles form settling layers in liquid media. Traditional level instruments often trigger false alarms or delayed responses under high solid concentration and fluctuating flow conditions, causing untimely sediment discharge and reduced efficiency.

With Tube-11, its dual-tube resonant design and precise tuning enable accurate detection of the sediment upper interface and automatic activation of discharge valves. Field data shows that regardless of sludge concentration changes, liquid flow fluctuations, or scraper operation cycles, Tube-11 provides stable measurement signals, maintaining sediments within preset limits. Compared with many high-end imported instruments, Tube-11 demonstrates higher stability and reliability during continuous long-term operation.

Customer feedback: Sediment discharge accuracy reaches over 98%, treatment efficiency improves by approximately 15%, and the frequency of manual inspections and on-site adjustments is significantly reduced. Maintenance is simple, requiring only periodic cleaning, which greatly lowers operating costs. Tube-11 has become a mature domestic alternative to imported high-end instruments, earning consistent praise from clients.

Fork-11 Tuning Fork Level Switch: Smart Solid-Liquid Interface Control

In addition to Tube-11, Jiwei offers the Fork-11 tuning fork level switch, designed for high/low point detection of solid materials. Fork-11 can detect granular, powdered, and low-density sediments, even when suspended in liquids, ensuring reliable triggering for alarms and automated control.

Combined Solution:

- Tube-11: Detects solid-liquid interface in sediments or sludge layers within liquids.

- Fork-11: Provides high/low level detection of solids, including low-density deposits, enabling safety interlocks and automatic control.

This combination has been widely applied in wastewater treatment plants, industrial water systems, and water utilities, significantly enhancing automation, operational safety, and reducing manual intervention and maintenance costs.

Technical Advantages

Rope-type Option: Both Tube-11 and Fork-11 offer rope-type versions suitable for tall tanks, deep pools, or hard-to-mount applications. Rope-type instruments accurately measure sediment interfaces in water, unaffected by liquid disturbances, scraper operation, or bubbles, ensuring long-term stable control.

VEGA Replacement & Fast Delivery: Performance parameters are comparable to or exceed VEGA products, making them perfect domestic alternatives. Jiwei ensures fast production and delivery, responsive service, and competitive pricing, providing cost-effective solutions for engineering projects.

Precise & Reliable: Tube-11’s dual-tube vibrating rod resonant tuning technology ensures accurate detection of solid sediment interfaces, responding quickly and outputting precise signals regardless of sediment particle size. Compared to traditional float or capacitive instruments, Tube-11 maintains long-term stability in complex media.

Strong Anti-Interference: Proprietary tuning and robust sensor structure prevent measurement signals from being affected by scrapers, bubbles, or flow disturbances, maintaining continuous and reliable sediment interface detection even under high-flow and variable sludge conditions.

Automation-Friendly: Both Tube-11 and Fork-11 provide control signals compatible with valves, pumps, or PLC/DCS systems for unattended automated operations, reducing human intervention and enhancing sediment handling efficiency.

Domestic Innovation: Fully patented, Jiwei Tube-11 and Fork-11 match or exceed the performance of imported high-end instruments, while offering lower cost and easier maintenance. Widely adopted in domestic water utilities and industrial water treatment projects, gradually replacing imported devices.

Multi-Scenario Applicability: Suitable for sedimentation tanks, regeneration tanks, sludge separation, and other challenging applications, unaffected by complex liquid media, simplifying design and maintenance while improving automation monitoring.

Expanded Applications & Industry Value

- Industrial wastewater treatment: Chemical, paper, food processing sedimentation pools

- Mining slurry management: Slurry, dust-liquid separation control

- Energy sector: Biogas slurry sediment monitoring

Benefits:

- Increased automation

- Reduced manual intervention

- Improved safety and equipment longevity

- Replacement of imported instruments, lowering overall investment

Conclusion

Accurate measurement of solid sediment interfaces is vital in wastewater treatment, industrial water systems, and water utilities. Jiwei’s Tube-11 vibrating rod level switch and Fork-11 tuning fork level switch provides a reliable, interference-resistant solution. Both offer rope-type versions for deep or complex installations, and serve as perfect VEGA replacements with identical parameters, short delivery times, rapid service, and competitive pricing.

Choosing Jiwei ensures high-precision sediment interface monitoring, enhanced automation, reduced operating costs, and improved process safety, providing long-term stable and reliable measurement for all water treatment applications.