Non-Contacting Radar Level Measurement: 24/7 Industrial Precision

Non-contacting radar level measurement is rapidly becoming one of the most reliable and efficient methods for measuring liquid and solid levels in various industries. This technology utilizes high-frequency microwave signals to determine the level of a material without the need for physical contact with the substance being measured. As industries strive for greater precision and safety, non-contacting radar level measurement stands out due to its superior accuracy, durability, and versatility.

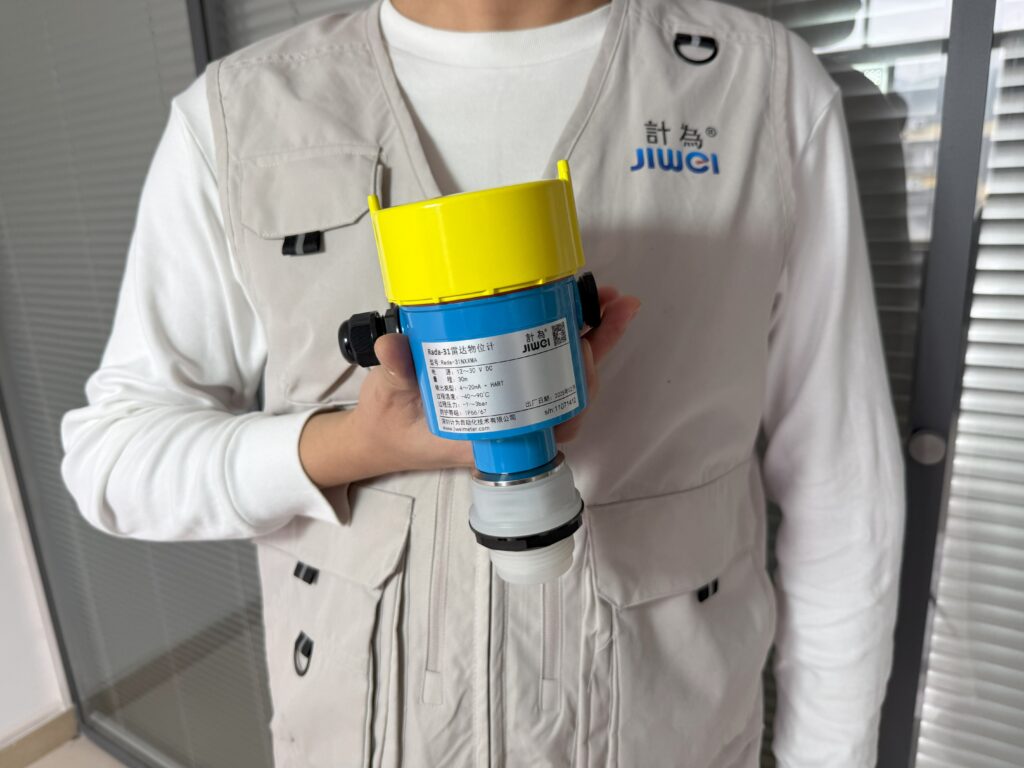

At the forefront of this innovation is Jiwei’s radar level measurement technology, offering cutting-edge solutions for a wide range of industrial applications. Whether you’re managing hazardous materials, bulk solids, or liquids, Jiwei’s non-contact radar level measurement systems are designed to enhance operational efficiency and safety.

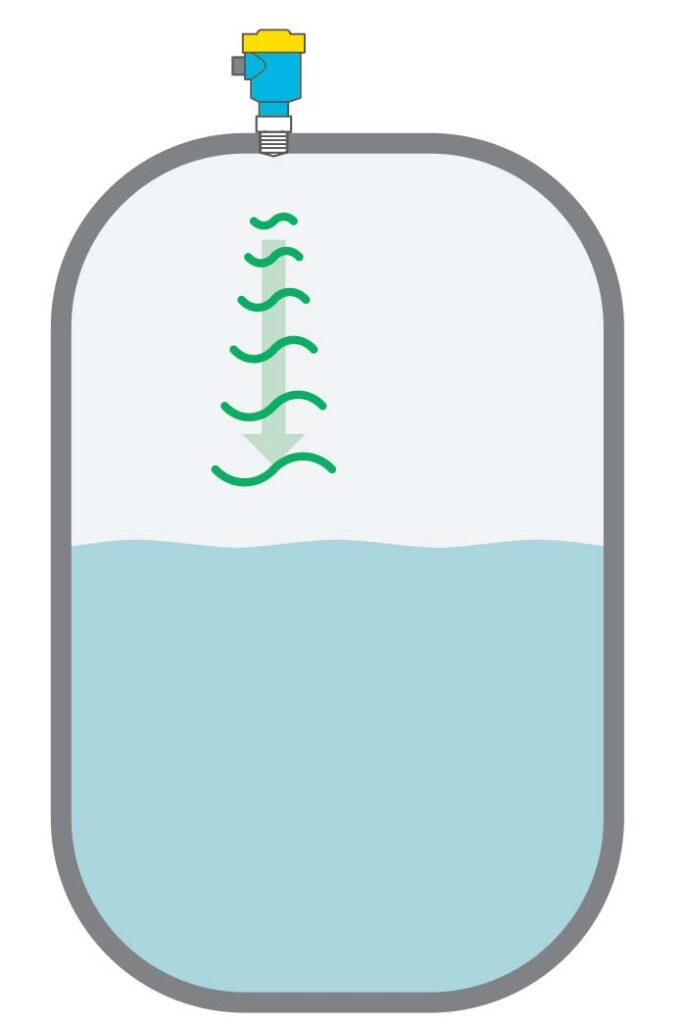

How Non-Contacting Radar Level Measurement Works

Non-contacting radar level measurement works by emitting high-frequency microwave signals from the radar sensor. These waves travel toward the surface of the material being measured. When the signal reaches the surface, it is reflected back to the sensor. The time it takes for the signal to return is directly proportional to the distance between the sensor and the material surface. This method allows for precise level measurements without the need for direct contact with the material.

Jiwei’s radar level measurement systems are equipped with advanced signal processing algorithms that ensure accuracy in challenging environments. The system compensates for environmental factors such as temperature, pressure, and density, making it ideal for a variety of applications, from hazardous material storage to chemical processing.

Key Advantages of Non-Contacting Radar Level Measurement

1. High Precision Measurement: Utilizing 80GHz high-frequency radar technology, Jiwei’s radar systems feature a narrow beam angle and a small dead zone, concentrating energy for high measurement accuracy. This ensures precise and reliable readings in a wide range of conditions.

2. Non-contact Measurement: Non-contact detection eliminates wear and tear on the sensor, extending the equipment’s lifespan and reducing maintenance costs. This technology is perfect for industries that require constant and consistent monitoring of levels.

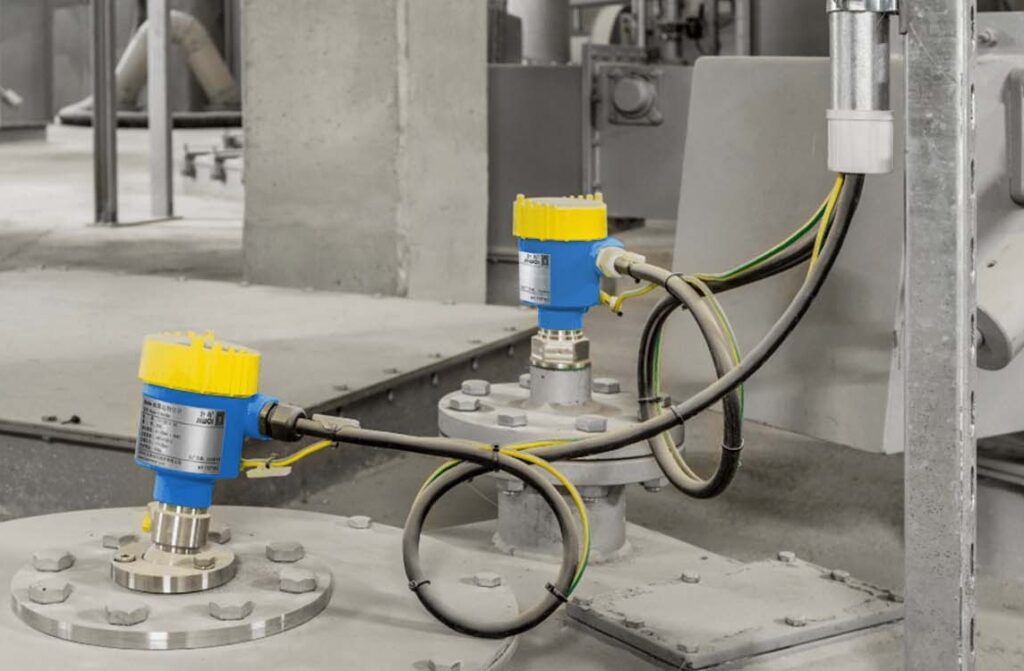

3. Easy Operation and Installation: Jiwei’s radar systems offer simple operation and easy installation, with support for flange and threaded installation options. Additionally, these systems are maintenance-free and come with professional installation guides, ensuring ease of use and a smooth setup.

4. Strong Adaptability: Jiwei radar systems are minimally affected by tank pipe sizes and obstacles, making them ideal for installation in narrow pipelines or confined spaces. Their versatility ensures accurate measurements even in challenging environments.

5. Strong Anti-interference Capability: Featuring a high signal-to-noise ratio, Jiwei’s radar systems deliver excellent anti-interference performance. This ensures stable measurement signals even in complex environments where noise or interference may affect other technologies.

6. Strong Stability and Resistance to Environmental Changes: Jiwei’s radar technology is virtually unaffected by environmental variations such as dust, steam, temperature, and pressure, making it highly suitable for use in harsh industrial environments.

7. Advanced Echo Processing Technology: Equipped with advanced echo processing technology, Jiwei radar systems provide stable and reliable signals, ensuring fast response times and real-time acquisition of precise data. This feature is essential for real-time monitoring and control in industrial applications.

8. Bluetooth Module Support: Jiwei radar systems are integrated with a Bluetooth 5.0 standard module, enabling wireless connectivity. This feature simplifies device debugging, data transmission, and maintenance, enhancing operational efficiency.

9. Wireless Communication Module: Jiwei radar sensors come with a wireless communication module and accompanying debugging software. This facilitates instrument optimization and enhances the overall user experience by making the setup and maintenance processes seamless.

Industry Applications for Non-Contacting Radar Level Measurement

1. Oil and Gas: Non-contacting radar level measurement is crucial in the oil and gas industry, where it is used to monitor tank levels, measure crude oil, and detect hazardous materials in storage tanks. The ability to operate in explosive atmospheres and extreme temperatures makes radar technology a safe and efficient solution for this sector.

2. Chemical Processing: In chemical processing, accurate level measurement is essential for maintaining safe and efficient operations. Jiwei’s radar systems are perfect for measuring highly corrosive and volatile chemicals, ensuring that manufacturers comply with safety standards while improving operational efficiency.

3. Food and Beverage: The food industry requires non-contacting, hygienic level measurement solutions. Jiwei’s radar level measurement systems are designed to meet food-grade standards, ensuring safety and precision in liquid storage tanks and processing vessels.

4. Wastewater Treatment: Radar level measurement is ideal for wastewater treatment facilities, where it is used to monitor sludge levels and other liquids in storage tanks. Jiwei’s radar technology helps optimize the treatment process and improve operational efficiency.

Jiwei Radar Level Measurement Technology

Jiwei’s radar level measurement systems are equipped with advanced features that make them a trusted solution across various industries. The Jiwei radar system utilizes high-frequency signals to ensure that even small changes in level are detected, providing high precision in measurements. Moreover, Jiwei’s radar level sensors are designed for easy installation, robust performance, and minimal maintenance, providing users with a reliable, long-lasting solution.

Jiwei’s radar technology also integrates seamlessly with other systems, offering the flexibility to connect with control systems for real-time monitoring and automation. With customizable configurations and a focus on user-friendly operation, Jiwei radar level measurement systems are built to meet the specific needs of each industry.

Conclusion

Non-contacting radar level measurement is a game-changer for industries seeking accurate, reliable, and cost-effective level measurement solutions. With Jiwei’s cutting-edge radar technology, businesses can improve operational efficiency, reduce maintenance costs, and ensure the safe handling of materials. Whether it’s monitoring hazardous liquids in oil and gas or managing solid levels in mining, Jiwei’s radar level measurement systems provide the precision and versatility needed to meet modern industrial demands.

Optimize your operations with Jiwei’s radar technology and ensure the highest level of accuracy in your processes today.