JWrada®-31 Radar Level Meter

The JWrada®-31 80GHz radar level meter features an integrated antenna, Bluetooth 5.0, and HART protocol. Ideal for pharmaceutical, food, energy, and hydrology industries, it ensures precise and maintenance-free liquid level measurement with advanced echo-learning technology for stable performance in complex environments.

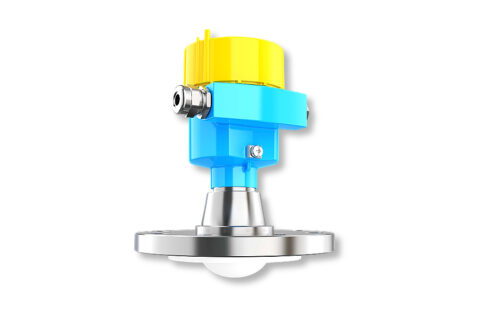

The JWrada®-31 Radar Level Meter features an integrated antenna design based on 80 GHz Frequency Modulated Continuous Wave (FMCW) technology, with a 36 mm antenna lens and a measuring range of up to 60 meters. It is suitable for liquid level measurement in non-explosion-proof areas.

The JWrada®-31 Radar Level Meter comes standard with HART communication protocol and a built-in Bluetooth 5.0 module. Paired with the “Jiwei Smart Control” WeChat applet, it enables wireless on-site configuration and monitoring for convenient operation. Remote configuration and monitoring are also possible via cloud data networks. Equipped with proprietary echo-learning adaptive algorithms, it can self-learn to identify false echoes, separate multiple echoes, and dynamically track targets. It automatically adapts to changing conditions, maintaining high-quality, precise measurements even in complex environments, ensuring long-term stable and reliable operation. The product is easy to operate and maintenance-free, designed for liquid level measurement in non-explosion-proof zones.

JWrada®-31 Radar Level Meter is widely used in liquid level measurement for pharmaceutical, food, energy, and hydrology applications.

The radar level meter emits a frequency-modulated continuous wave (FMCW) high-frequency (80 GHz) electromagnetic signal through its antenna, with the frequency increasing linearly over time. It receives the electromagnetic wave reflected from the material surface. The periodically transmitted FMCW signal mixes with the reflected echo to produce an intermediate frequency (IF) signal. By analyzing the frequency spectrum of this IF signal using a Fast Fourier Transform (FFT), the flight time of the signal (TDR) is indirectly measured. Combining this with the speed of light, the radar level meter calculates the distance between the antenna and the material surface, thereby accurately determining the level height.

● High Precision: 80GHz FMCW radar with ±1 mm accuracy, 60 m range, and no blind zone.

● Bluetooth & Smart Control: Built-in Bluetooth 5.0, supports “Jiwei Smart Control” WeChat mini-program and cloud monitoring.

● Intelligent Echo Processing: Self-developed platform with false echo suppression, multi-echo separation, and dynamic tracking for stable measurement in steam, dust, and stirring.

● Environmental Stability: Unaffected by temperature, pressure, steam, or dust; high signal-to-noise ratio ensures strong anti-interference.

● Non-Contact & Durable: Prevents wear, corrosion, and contamination, reducing maintenance.

● Easy Installation: Compact design with flange/thread options and intuitive software.

● Application: Ideal for liquid level measurement in non-explosion-proof areas such as pharmaceutical, food, energy, and hydrology.

| Features | Economical 80GHz high-frequency radar level meter with wide applicability | |

| Application | For continuous non-contact liquid measurement in complex containers in pharmaceutical, food, energy, and water industries | |

| Measurement Parameter | Frequency | 80GHz |

| Measuring Range | 60m | |

| Beam Angle | ≥3° | |

| Accuracy | ±1mm | |

| Material | Antenna | PFA, 316L+PTFE, 316L+PFA |

| Housing | Aluminum alloy | |

| Installation | Process Connection | Flange, Thread, Bracket, Suspension |

| Power Supply | Two-wire | 12~30V DC |

| Four-wire | 12~30V DC | |

| Signal Output | Two-wire | 4~20mA/HART |

| Four-wire | RS485/Modbus | |

| Bluetooth | Support Bluetooth® v5.4 | |

| Operating Environment | Process Pressure | -1 – 30 bar |

| Process Temperature | -40℃~150℃ | |

| Ambient Temperature | -40℃~80℃ | |

| Storage Temperature | -40℃~80℃ | |

| Safety Certification | Ingress Protection | IP66/67, IP68 |

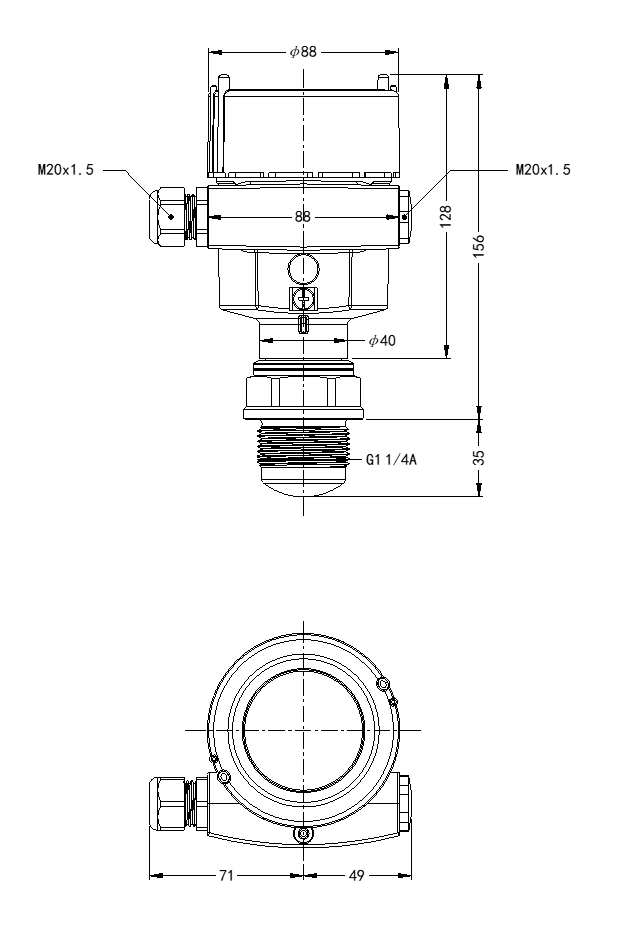

| Cable | Cable Entry | M20×1.5, 1/2NPT |

● Widely used for non-contact level measurement in pharmaceutical mixing tanks, reactors, and other vessels, fully meeting stringent hygiene standards.

● Suitable for monitoring mixing and fermentation tanks in the food industry to ensure product safety and process reliability.

● Applicable to condensate and lube oil tanks in the energy sector, delivering stable performance under high temperature and pressure variations.

● Ideal for hydrology and water utilities, including dosing tanks and sedimentation basins in water treatment processes.