What Is a Flange? Discover Its Functions and Pressure Ratings Like a Pro

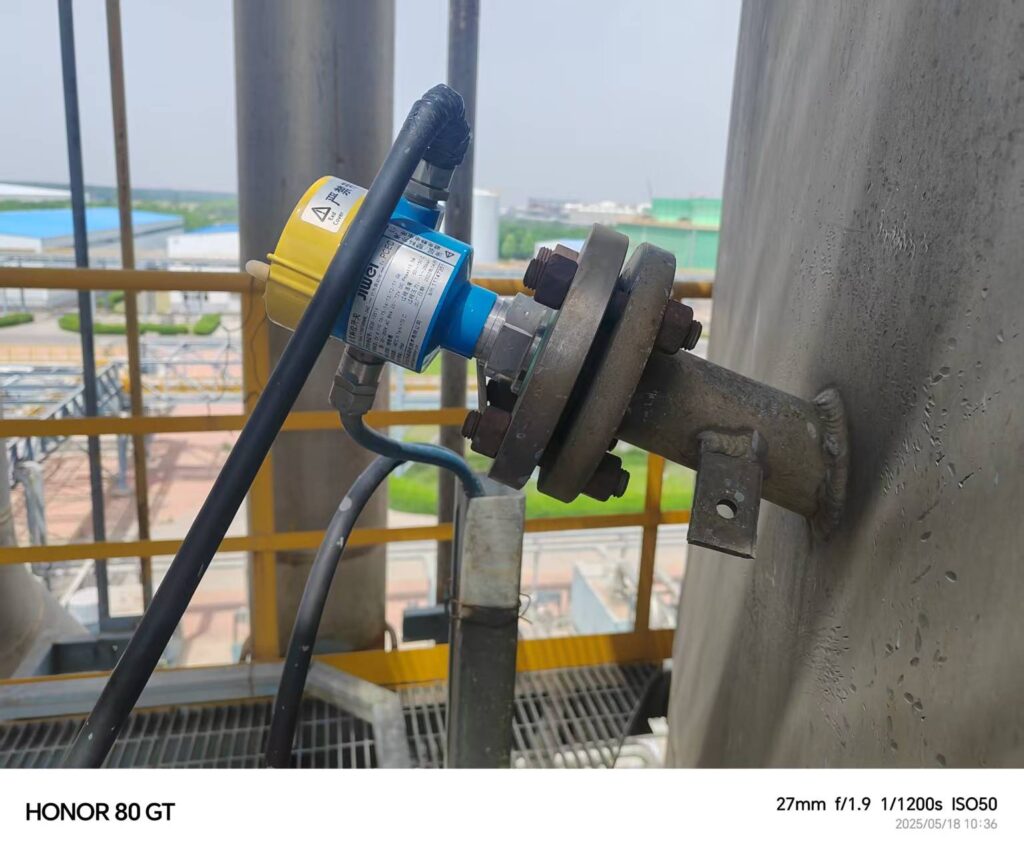

What Is a Flange and How Does It Work?

A flange is a mechanical component used to connect pipes, valves, pumps, or other equipment in a piping system. It is typically a flat disc with holes that allow it to be fastened to another flange using bolts. The flanges are sealed together with gaskets to ensure a leak-free joint. Flanges are also called flange plates or flange joints.

Flanged connections are widely used in pipeline construction and equipment installation because they are reliable, easy to assemble and disassemble, and can handle high pressure. The thickness and bolt strength of a flange vary depending on the required pressure rating. a Flange

Understanding Flange Pressure Ratings (Nominal Pressure PN)

The nominal pressure (PN) of a flange refers to a standardized pressure level that defines the maximum allowable working pressure at a reference temperature. It is used as a design parameter and is usually slightly higher than the actual working pressure. a Flange

The pressure rating is expressed in megapascals (MPa) or bars. For example, PN10 means the flange can handle up to 10 bar (≈1.0 MPa) at the reference temperature.

➤ Common Pressure Ratings in International Systems:

- European (SI-based) System (DIN standards):

- PN 0.25, 0.6, 1.0, 1.6, 2.5, 4.0, 6.3, 10.0, 16.0, 25.0 MPa

- American System (ASME B16.5 / B16.47):

- PN 2.0, 5.0, 11.0, 15.0, 26.0, 42.0 MPa (approximate conversions)

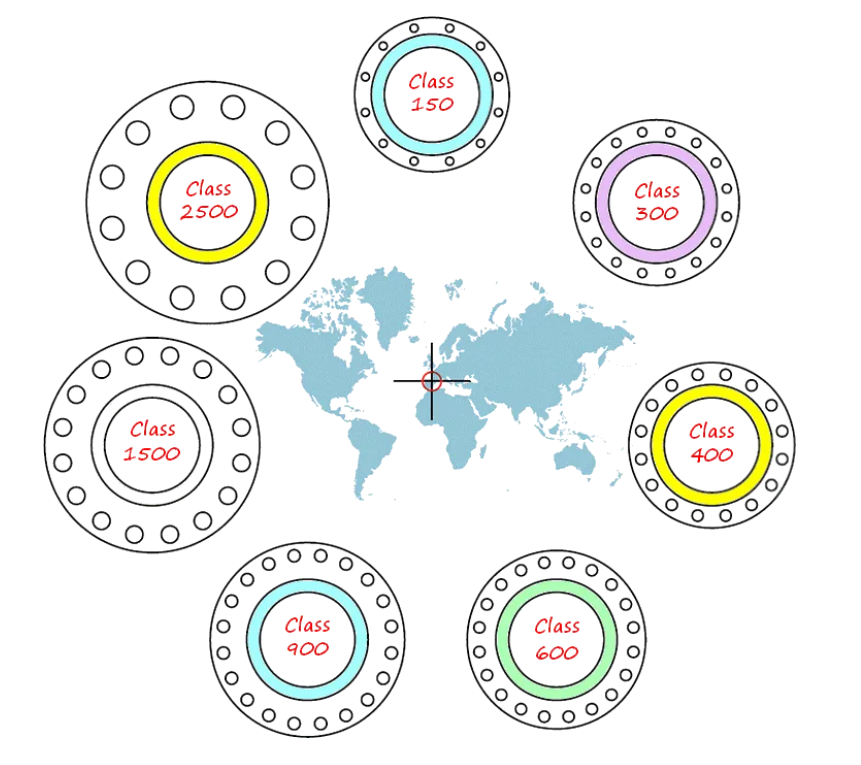

➤ PN vs. Class Pressure Ratings

In the U.S. and some other countries, flange pressure ratings are often represented in pound classes (Class) such as Class 150, 300, 600, etc. These can be compared with SI pressure classes as follows:

| PN (MPa) | Class (lbs) |

|---|---|

| 2.0 | 150 |

| 5.0 | 300 |

| 11.0 | 600 |

| 15.0 | 900 |

| 26.0 | 1500 |

| 42.0 | 2500 |

It is important to note that flanges from different systems (e.g., DIN vs. ASME) are not interchangeable, even if their pressure ratings seem similar. Connection dimensions and sealing surfaces differ between systems.

Material and Temperature Effects on Flange Pressure

The actual working pressure of a flange is influenced by several factors:

- Material: Carbon steel, stainless steel, and alloy steel each have different pressure tolerances.

- Temperature: As temperature increases, the strength of the flange material may decrease, reducing the safe working pressure.

- Corrosive Media: Chemicals in the process fluid may weaken the flange material or require special alloys.

- Flange Design: Welding neck flanges, slip-on flanges, socket weld flanges, and others vary in strength and application.

Therefore, while nominal pressure (PN) is a design reference, engineers must evaluate actual operating conditions—including temperature and media characteristics—when selecting the proper flange rating.

Types of Flanges and Their Applications

Flanges come in various types, each suited for specific applications and pressure requirements. Choosing the right flange type is essential to ensure a proper seal and structural integrity in the piping system.

Here are the most common flange types:

- Weld Neck Flange: Designed with a long tapered hub that provides excellent stress distribution. It is ideal for high-pressure and high-temperature environments, often used in oil & gas, power plants, and petrochemical facilities.

- Slip-On Flange: Slips over the pipe and is welded both inside and outside. Easier to install but less robust than weld neck flanges, commonly used in low-pressure systems.

- Socket Weld Flange: Features a socket into which the pipe is inserted and fillet-welded. Suitable for small-diameter, high-pressure piping systems.

- Blind Flange: Used to close off the end of a pipe or valve opening. It does not have a center hole and must withstand system pressure during shut-off.

- Lap Joint Flange: Used with a stub end, allowing for easy alignment and rotation. Often used where frequent dismantling is required.

- Threaded Flange: Screwed onto pipes without welding. Mostly used in small-diameter piping systems with low pressure.

Each flange type offers different mechanical advantages. Selection depends on factors such as pressure class, installation requirements, temperature, material compatibility, and system maintenance needs. Using the appropriate flange type enhances safety, reduces downtime, and ensures compliance with piping codes and standards.

Flange Safety and Design Considerations

In system design, it is standard practice to choose a nominal pressure rating higher than the operating pressure, allowing a margin of safety. If operating temperatures exceed the reference level, pressure correction must be applied according to material pressure-temperature rating charts. Always ensure that the flange’s pressure capacity at the operating temperature does not exceed its rated limit.

Conclusion

Understanding what a flange is and how its pressure rating works is crucial in designing safe and reliable piping systems. Whether using the PN system in Europe or the Class system in the Americas, proper flange selection depends on pressure, temperature, material, and applicable standards. Accurate specification prevents failure and ensures system integrity.