A Practical Guide to Pressure Units, Conversions, and Engineering Best Practices

1. Definition of Pressure and SI Units

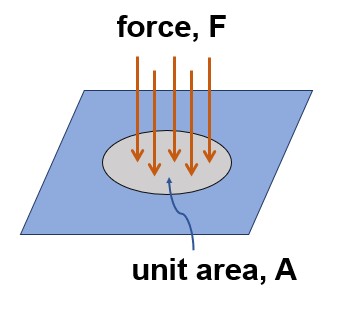

Pressure refers to the force applied per unit area, defined as:

P = F / A (Force / Area)

In the International System of Units (SI), the base unit of pressure is the Pascal (Pa), where:

1 Pa = 1 N/m²

Because Pa is too small for practical engineering use, its multiples are commonly applied:

- kPa (kilopascal)

- MPa (megapascal) — the most widely used in Chinese engineering, pressure vessels, pump systems, and structural design

For example, material yield strength is typically expressed in MPa.

2. Common Pressure Units and Their Origins

Different industries adopt different pressure units due to historical standards or measurement methods. The most used units include:

1) bar and mbar

Used in meteorology and gas compression systems

1 bar = 100,000 Pa = 0.1 MPa

2) Standard atmosphere (atm, at)

Used in chemical processes and laboratory conditions

- 1 atm = 101,325 Pa

- 1 at = 98,066.5 Pa (defined by water column weight)

3) mmHg and cmH₂O

Used in medical systems, ventilation measurement

- 1 mmHg = 133.322 Pa

- 1 cmH₂O ≈ 98.0665 Pa

4) psi (pounds per square inch)

Common in North America, oil & gas, tire pressure

- 1 psi = 6,894.76 Pa ≈ 0.00689476 MPa

3. Quick Conversion Table for Engineering Use

| Unit | Pa | MPa |

|---|---|---|

| 1 Pa | 1 | 1×10⁻⁶ |

| 1 kPa | 1,000 | 0.001 |

| 1 MPa | 1,000,000 | 1 |

| 1 bar | 100,000 | 0.1 |

| 1 atm | 101,325 | 0.101325 |

| 1 at | 98,066.5 | 0.0980665 |

| 1 mmHg | 133.322 | 1.33322×10⁻⁴ |

| 1 psi | 6,894.76 | 0.00689476 |

This table allows quick conversion for engineering design and calculations.

4. Key Considerations in Engineering Applications

1) Gauge vs. Absolute Pressure

In real projects, pressure can be expressed in two forms:

- Gauge pressure (kPa(g) / MPa(g))

Zero reference = atmospheric pressure - Absolute pressure (kPa(a) / MPa(a))

Zero reference = absolute vacuum

Relationship:

P_abs = P_gauge + P_atm

Example:

A pipeline showing 0.5 MPa(g) actually means ≈0.601 MPa(abs).

Vacuum readings may appear negative, such as -0.08 MPa(g).

Failing to distinguish these can cause major errors in gas density, flow, and compressibility calculations.

2) Consistent Units Across Equipment and Documentation

Imported equipment such as compressors, valves, and cylinders may use psi or bar, while domestic designs typically use MPa.

Incorrect conversion might result in:

- wrong pressure rating selection

- insufficient design margin

- safety risks

Therefore, unit standardization is essential during engineering reviews.

3) Instrument Output vs. Control System Configuration

Pressure transmitters may output:

- MPa

- bar

- psi

- %FS (percentage of full scale)

PLC/DCS configuration must match the transmitter unit to avoid misleading readings.

4) High-Risk Industries Must Avoid Unit Mixing

Natural gas, petrochemical, and gas distribution systems may simultaneously use kPa, MPa, bar, psi depending on pressure sections and equipment origin.

Industry standards require strict consistency to prevent operational errors.

5. How to Convert Units Efficiently in Real Work

1) Use the “Base Unit Method”

Convert all values to Pa first, then convert to the target unit to avoid chained calculation errors.

2) Use engineering software or simple scripts

MATLAB, Python, engineering calculators, PLC conversion blocks, or vendor tools help ensure accurate and traceable calculations.

3) Always specify units in technical documents

Good technical documentation should:

- use unified units (MPa(g), kPa(abs), psi(g))

- provide full unit terms on first use

- avoid ambiguous abbreviations

6. Conclusion

Pressure units may appear simple on the surface, yet they directly impact almost every aspect of industrial engineering—from mechanical design, equipment selection, and piping calculations to instrumentation configuration and safety interlocks. A small mistake in unit conversion can lead to oversized or undersized components, inaccurate pressure readings, unstable control loops, or even safety incidents in high-risk environments. Whether the system involves compressed gases, hydraulic circuits, chemical reactors, steam networks, or vacuum processes, correct pressure unit handling is fundamental to ensuring accuracy and operational reliability.

A clear understanding of how different pressure units originated, how they relate to each other, and how they are used in various industries helps engineers avoid unnecessary design revisions, communication errors, or equipment mismatches. When pressure units are mixed—such as psi on imported valves, bar on compressor datasheets, and MPa in local design drawings—the potential for confusion grows rapidly. Systematic knowledge and consistent application of pressure units greatly reduce engineering risks, especially during cross-team coordination, international project execution, and multidisciplinary reviews.

For engineers, developing a standardized and disciplined approach to pressure units is more than a basic skill—it is a core part of professional competence. This includes selecting the correct unit system, performing accurate conversions, maintaining unit consistency in technical documents, and verifying instrument settings before commissioning. When engineers adopt these practices regularly, the entire workflow—from design to installation to operation—becomes more robust, predictable, and safe. In fast-paced engineering environments where precision matters, mastering pressure units is a small investment that delivers significant long-term benefits.