Finally Clear: Why Jiwei Level Switches with EAC Certification Require Both TR CU 012 + TR CU 020 for True Engineering Value

When exporting to Russia, Kazakhstan, Belarus, and other Eurasian Economic Union (EAEU) countries, EAC certification is almost universally the first regulatory hurdle for industrial instruments. Many devices can enter these markets once the mark is obtained. However, for level switches, which directly impact production safety and plant reliability, simply having an EAC mark is far from sufficient.

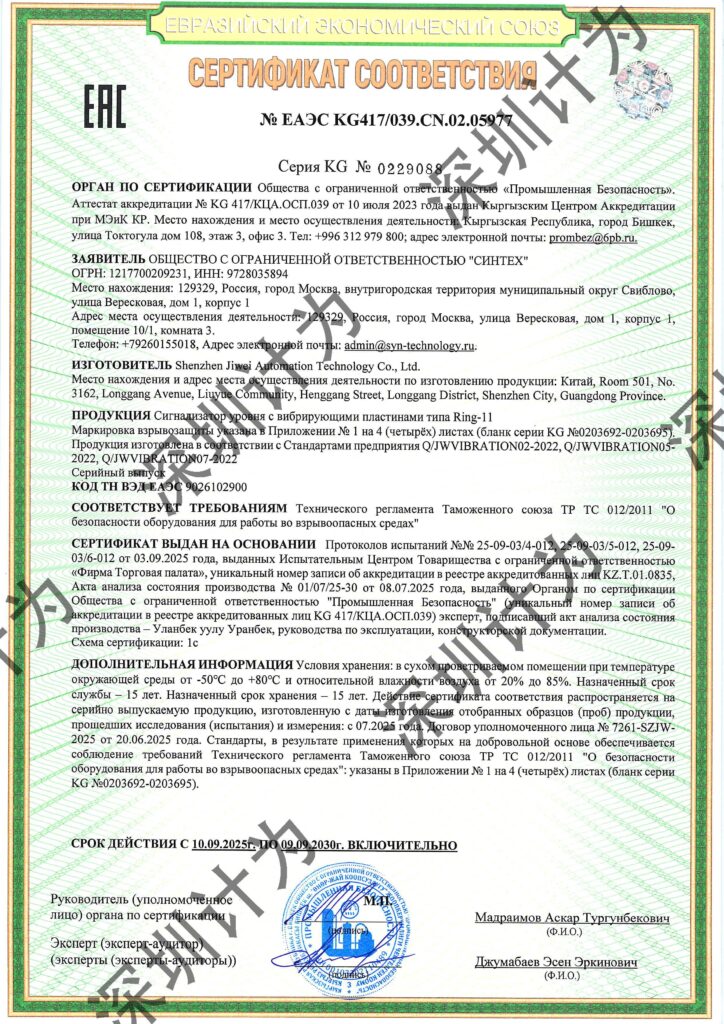

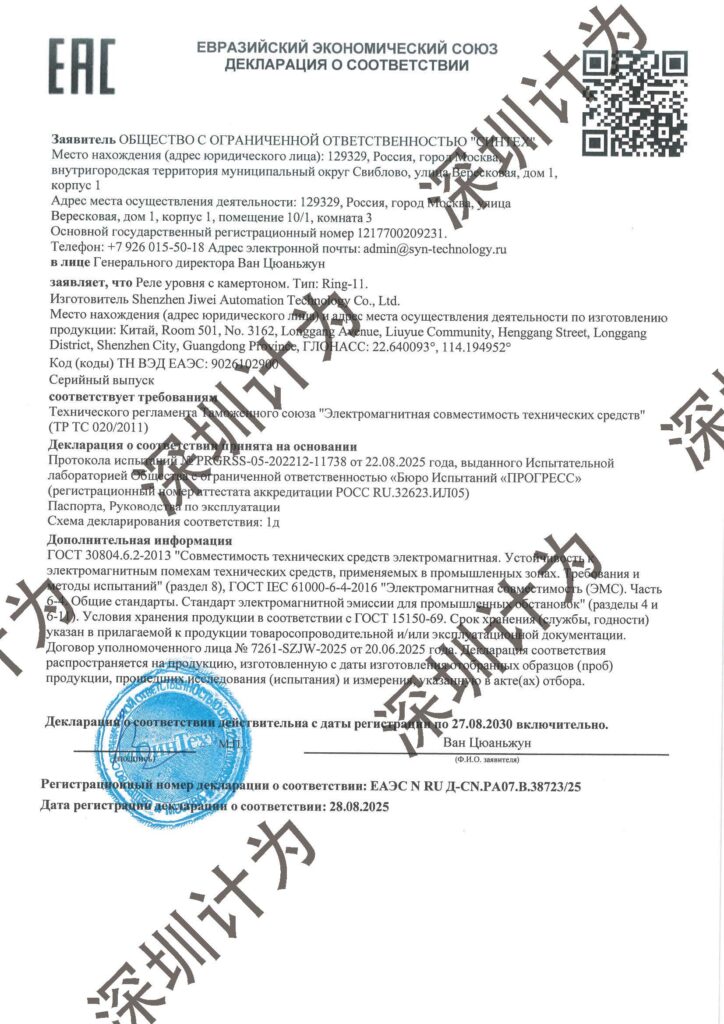

Jiwei level switches from Shenzhen Jiwei Automation have not only obtained EAC certification, but also comply with TR CU 012 (explosion-proof equipment) and TR CU 020 (electromagnetic compatibility, EMC). This dual compliance is widely recognized in the industry as having higher “engineering value” and more accurately reflects true operational reliability.

Why do level switches need both standards? Why do some manufacturers only comply with TR CU 020 while Jiwei achieves both? And why does this combination offer substantial practical value for clients?

1. Level Switches Face Two Overlapping Risk Scenarios

Many industries consider level switches “small components,” but in real-world operation, they carry significant responsibility.

Level switches are typically installed in environments with two overlapping risks:

Explosive environment risk: In chemical, oil & gas, fine chemical, paint production, battery electrolyte, and solvent storage scenarios, many media are flammable. Improper handling, sparks, temperature rise, or static electricity could result in severe accidents. Therefore, the level switch must meet Ex design requirements in structure, explosion-proof housing, and circuitry.

Electromagnetic interference (EMI) risk: Modern plant environments are increasingly complex, with frequent sources of interference such as variable frequency drives, motor startups, heating equipment, solenoid valves, PLCs, and communication cables. Level switches, being low-signal devices, are susceptible to EMI, which can cause false alarms, delayed responses, or failures, creating hidden risks for control systems.

When these two risks coexist, devices must meet both explosion-proof and EMC standards. Otherwise, the equipment might either “not explode but misoperate” or “resist interference but fail in hazardous zones.” Many engineers may not realize that a truly reliable industrial level switch must comply with both TR CU 012 and TR CU 020.

2. Key Differences Between TR CU 012 and TR CU 020

Understanding the “value” difference requires looking at the core of these two standards.

TR CU 012 (explosion-proof equipment) is one of the strictest EAEU regulations. It requires testing by authorized laboratories, including:

- Explosion-proof structure verification

- Mechanical strength and sealing checks

- Temperature rise tests

- Circuit energy limitation analysis

- Material and anti-static requirements

- Third-party CoC certification

- Factory quality system audits, if required

In short, TR CU 012 ensures the device will not become an ignition source in hazardous areas.

TR CU 020 (EMC) focuses on the device’s electromagnetic performance, including:

- Immunity to interference (EFT, ESD, radiated immunity, etc.)

- Radiated and conducted emissions

- Compatibility with control systems

- Influence on PLCs and field instruments

Simply put, TR CU 020 ensures the device operates reliably without causing interference.

Many manufacturers only pursue TR CU 020, as it can be self-declared via DoC, which is less costly and faster. TR CU 012, however, requires third-party CoC certification, involves stricter testing, and demonstrates stronger engineering capability.

3. Why Jiwei Level Switches Achieve Both TR CU 012 + TR CU 020

Jiwei level switches are developed for complex industrial environments, making dual compliance achievable due to several key factors:

1. Mature Intrinsically Safe (Ex ia) Design

During development, circuits are designed to limit energy, provide isolation, prevent sparks, control temperature rise, and maintain electrical clearances. This allows the switches to pass TR CU 012 explosion-proof audits successfully.

2. Reinforced EMC Design

Internal circuits include filtering, isolation, power stabilization, and signal shaping to maintain stable output even in high-interference environments, ensuring excellent performance under TR CU 020 testing.

3. Robust Mechanical Structure

Explosion-proof housings, sealing, electronic compartments, and modular assembly meet hazardous area instrument requirements.

4. Proven Multi-industry Reliability

From chemical plants, lubricants, food factories, to breweries, coffee bean silos, feed mills, and gear oil equipment, Jiwei level switches demonstrate long-term stability, supporting the credibility of EAC certification.

5. Complete Quality System

EAC inspections evaluate product consistency and production systems. Jiwei’s complete and standardized quality system ensures that certified samples represent bulk production.

4. Why Dual Compliance Offers Higher Engineering Value

From an engineering perspective, dual TR CU 012 + TR CU 020 compliance offers clear advantages beyond single-standard devices.

If a device only has TR CU 020 (EMC), it maintains stable signals in complex electromagnetic environments, resisting interference from drives, motors, heaters, and control systems. However, it cannot enter explosive hazardous zones, limiting deployment in flammable gas, vapor, or dust environments.

If a device only has TR CU 012 (explosion-proof), it can safely operate in hazardous areas (Zone 1 / Zone 2), but may not be fully immune to electromagnetic interference. In chemical lines, energy plants, food solids transport, feed mills, or electrolyte preparation systems, high-frequency pulses, transients, and motor start-up disturbances may induce false alarms, delayed triggers, or failures, impacting PLCs, DCS, or SIS and increasing operational uncertainty.

When a device complies with both standards, its engineering value becomes clear. Jiwei level switches are certified for both, allowing safe operation in hazardous zones while maintaining stable outputs in high-interference environments. This is especially critical for applications such as fine chemicals, lubricants, gear oils, battery electrolytes, solvents, and other industrial liquids.

Dual certification also facilitates approval by design institutes, general contractors, and clients, as devices meet both safety and operational reliability requirements. It ensures unrestricted deployment in critical production units, including alarm interlocks and limit points, supporting long-term stable operation.

From a reliability perspective, both “hazardous area suitability” and “strong EMI immunity” are essential. Dual compliance ensures the device can handle high-risk, high-demand industrial conditions. This is not just compliance—it directly supports system stability, reduces false actions, and enhances continuous production reliability.

5. Practical Value for Overseas Projects

In Russia, Central Asia, and Eastern Europe, engineering projects typically require:

- TR CU 012 CoC

- TR CU 020 DoC

- Explosion-proof structure documentation

- EMC test reports

- Hazardous area suitability declaration

Dual-certified Jiwei level switches improve:

- Bid competitiveness

- Design institute acceptance

- Equipment approval rate

- Project acceptance success

- Long-term operational safety and stability

For EPCs, integrators, and end users, this translates into lower engineering risk and higher system reliability.

6. Conclusion

Not all EAC certifications are equal. Not all explosion-proof devices can resist interference. Not all EMC-compliant instruments are suitable for hazardous zones.

Only level switches certified for both TR CU 012 + TR CU 020 can truly meet the engineering demands of complex industrial environments.

This dual compliance is a key reason why Jiwei level switches from Shenzhen Jiwei Automation continue to expand their presence in overseas markets.