Importance of Explosion-Proof Radar Level Meters

In industries such as petrochemical, coal chemical, energy, pharmaceutical, and grain processing, accurate liquid and bulk material level monitoring is critical for ensuring production safety and operational stability. Conventional level meters often fail in high-temperature, steam-rich, dusty, and complex media environments, whereas explosion-proof radar level meters, with their exceptional technical performance, are increasingly becoming the industry standard.

These meters not only operate safely in flammable and explosive environments but also provide high-precision, stable, and intelligent measurement under complex process conditions, offering enterprises comprehensive safety and efficiency assurance.

Eight Core Advantages

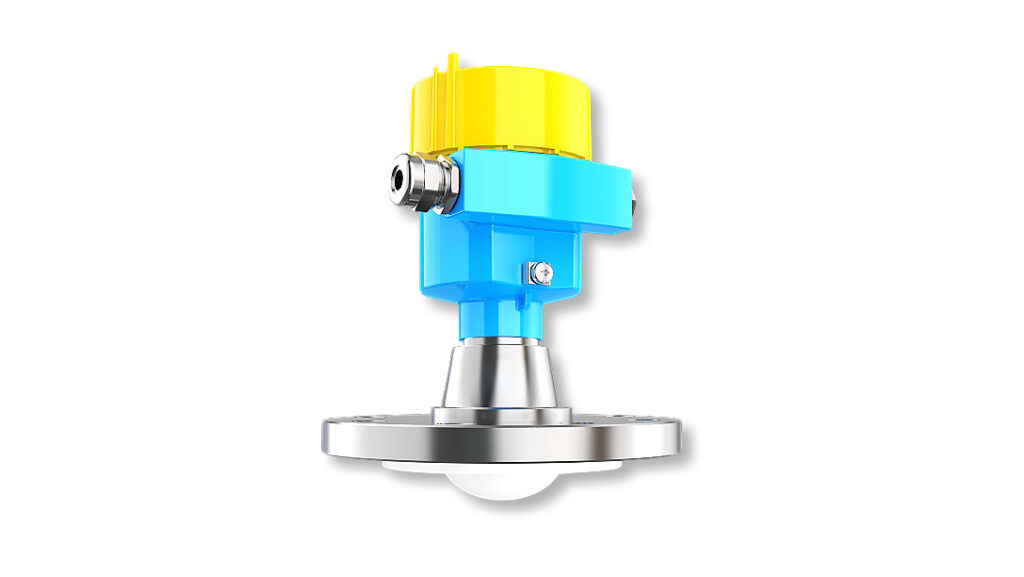

High-Precision Measurement

Explosion-proof radar level meters deliver accuracy up to ±1 mm for liquids and 0.1% for bulk solids, with a maximum measuring range of 120 meters. They maintain high resolution and stability even for low-dielectric powders, solid particles, and complex bulk material piles.

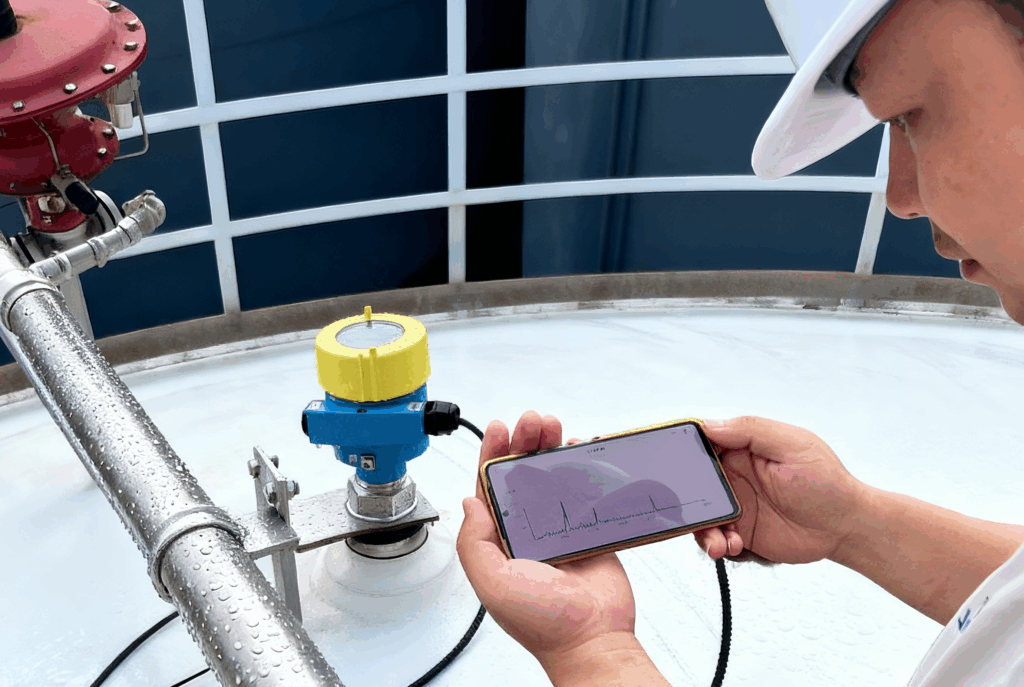

Bluetooth Configuration

Equipped with Bluetooth 5.0, the meter works with the Jiwei Smart Control WeChat mini-program for wireless on-site configuration, parameter setting, and remote monitoring. No wiring is required, significantly enhancing operational efficiency.

Intelligent Echo Processing

Using proprietary echo processing algorithms, the meter can identify false echoes, separate multiple-layer echoes, and track dynamic targets accurately. High precision is maintained even under steam, foam, or turbulent conditions.

Strong Anti-Interference Capability

Designed with a high signal-to-noise ratio, the meter can reliably handle interference from agitators, steam, dust, and electromagnetic noise, ensuring continuous and accurate data output.

High-Temperature Resistance

The device can withstand working temperatures of up to 220°C, suitable for chemical reactors, steam boilers, and other high-temperature processes, guaranteeing long-term operational stability.

Comprehensive Explosion Protection

Certified with flameproof, intrinsic safety, and dust explosion protection (Ex db IIC T6 Gb; Ex ia IIC T6 Ga; Ex tb IIIC T80℃ Db; Ex ia IIIC T200 80℃ Da), the meter can be safely installed in petrochemical storage tanks, coal chemical plants, and pharmaceutical workshops.

Corrosion-Resistant Design

Constructed with corrosion-resistant alloys and fully sealed structures, with critical parts equipped with PTFE diaphragms, it performs reliably in highly corrosive media such as strong acids and bases.

Environmental Adaptability

The small beam angle focuses electromagnetic energy, enabling precise measurement even under steam or foam layers. It is also suitable for low-dielectric powders and large bulk material silos, meeting the challenges of dusty and harsh industrial environments.

Industry Applications

Petrochemical Industry

In petrochemical storage tanks, refineries, and fine chemical plants, flammable, explosive, and toxic liquids or gases such as crude oil, methanol, and benzene are commonly stored. Conventional level meters often fail in high-temperature and steam-rich environments. Explosion-proof radar level meters, with millimeter-level accuracy and 220°C high-temperature resistance, provide real-time level monitoring, preventing overfilling or leakage accidents. Their full explosion-proof design ensures safe operation in areas with explosive gas mixtures, complying with industry safety and environmental regulations.

Coal Chemical & Energy Industry

Coal slurry pools, ash ponds, and gasifier feed silos often face high temperatures, high pressure, dust, and steam interference. With a focused beam and strong signal processing, the meter penetrates steam and dust to detect the true level, avoiding system downtime due to measurement errors. In thermal power plants, boilers, and fuel tanks, explosion-proof radar level meters enhance measurement reliability, reduce manual inspections, and meet the energy sector’s requirements for safety, continuous operation, and low maintenance.

Pharmaceutical & Fine Chemical Industry

Pharmaceutical processes often use highly flammable solvents like ethanol and acetone. Failure in level measurement can lead to explosion hazards. Explosion-proof radar level meters, certified with intrinsic safety and flameproof protection, can be safely installed in reactors, extraction tanks, and solvent storage tanks. The PTFE diaphragm corrosion-resistant design resists acidic and alkaline media, ensuring long-term stability. This helps enterprises meet GMP compliance while reducing downtime and maintenance costs.

Grain & Bulk Material Storage

Grain silos, cement, and mineral storage often face challenges such as tall silos (tens of meters), high dust concentration, and low dielectric constants. Explosion-proof radar level meters, with 120-meter range and low-dielectric adaptability, accurately monitor large-capacity silos, preventing overflow or underfill disruptions. Their explosion-proof design also reduces dust explosion risks, making them ideal for grain, feed, and cement industries.

Food & Beverage Industry

Processes such as alcohol fermentation and beer brewing generate foam and steam, which interfere with conventional level meters. Explosion-proof radar level meters, equipped with intelligent echo processing, can separate multi-layer echoes, avoiding interference from foam or condensation. Explosion-proof capability ensures safety in flammable production zones, complying with both food safety and production regulations.

Environmental & Hazardous Waste Treatment

In wastewater treatment plants and hazardous waste tanks, level measurement often involves highly corrosive or toxic liquids, such as concentrated acids, bases, or waste oil. Explosion-proof radar level meters, with corrosion-resistant materials and sealed design, ensure long-term operation while preventing spark-induced accidents. Remote monitoring enables operators to track levels from control rooms, minimizing exposure to hazardous environments.

User Needs & Value Proposition

Enterprises choose explosion-proof radar level meters to:

- Ensure production safety: Comply with explosion-proof and intrinsic safety requirements.

- Enhance measurement accuracy: Millimeter-level precision supports reliable process control.

- Reduce operational costs: Bluetooth configuration and intelligent algorithms minimize manual inspections.

- Adapt to diverse conditions: Stable performance in high temperature, dust, steam, and corrosive media.

Explosion-proof radar level meters are more than just measurement instruments—they are strategic solutions for safety compliance, intelligent production, and cost-efficiency improvement.

Comparison: Conventional vs Explosion-Proof Radar Level Meters

| Feature | Conventional Level Meter | Explosion-Proof Radar Level Meter |

|---|---|---|

| Measurement Accuracy | Centimeter level | ±1 mm for liquids, 0.1% for bulk solids |

| Maximum Range | < 40 m | Up to 150 m |

| Temperature Resistance | ≤150°C | Up to 220°C |

| Anti-Interference | Sensitive to steam and dust | Intelligent echo + high SNR, strong interference resistance |

| Explosion Protection | None | Flameproof + intrinsic safety + dust explosion-proof |

| Communication & Configuration | Wired settings | Bluetooth 5.0 + remote monitoring |

| Corrosion Resistance | Standard materials | PTFE diaphragm + corrosion-resistant design |

| Industry Application | Water treatment, food | Chemical, petrochemical, coal chemical, pharmaceutical, energy |

Conclusion

As industrial processes become more complex, traditional level measurement methods can no longer meet the dual requirements of safety and precision. Explosion-proof radar level meters, with millimeter-level accuracy, 150-meter range, 220°C high-temperature tolerance, Bluetooth configuration, and intelligent echo processing, comprehensively solve measurement challenges in high-risk industries.

For enterprises seeking safe production, intelligent management, and operational efficiency, explosion-proof radar level meters are not only essential—they are a key tool to enhance competitiveness.

📖 References

- CNCA. (2023). China Compulsory Certification (CCC) for Explosion-Proof Equipment. Certification and Accreditation Administration of the People’s Republic of China.

- API. (2021). API Standard 2350: Overfill Protection for Storage Tanks in Petroleum Facilities. American Petroleum Institute.