Jiwei Empowers Automotive Precision Casting Manufacturer with Reliable Level Switches

🚗 The Cornerstone of Precision Casting in the Automotive Industry

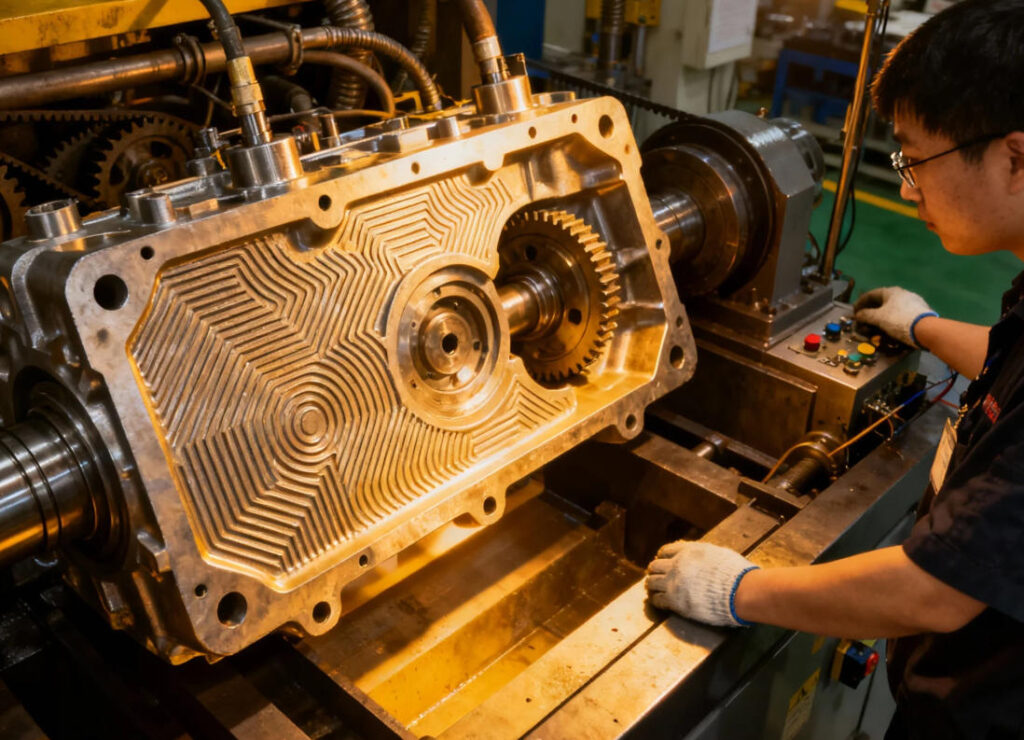

As the automotive industry moves toward lightweight design, high performance, and new-energy platforms, the demand for precision manufacturing is steadily rising. Key engine and transmission components—especially the complex cooling and lubrication channels inside internal-combustion engines—act as the “heart” of the vehicle. Because these internal passages are highly irregular, manufacturers rely on precision casting technology for stable, scalable production — and a reliable level switch plays an essential role in keeping the entire process under control.

In East China, particularly in the advanced manufacturing clusters around Suzhou, numerous high-level automotive mold and casting equipment suppliers are concentrated. The Suzhou equipment manufacturer visited by Jiwei is a crucial link in this supply chain, specializing in designing and producing precision casting equipment for automotive core components.

Complexity and High Standards of Precision Sand Casting

The customer’s core process is not traditional sand casting but advanced precision sand casting, often combined with shell molding or cold-box core techniques, to ensure extremely high dimensional accuracy and surface finish in internal passages.

- Mold media: They use fine, strictly sieved sand, often mixed with resin or other binders, rather than coarse sand. The sand forms a hard and highly permeable mold or core through heating or chemical reaction.

- Product usage: These molds are single-use consumables. Once the automotive OEM pours molten aluminum or cast iron into these molds, the molds decompose under high temperatures and are removed after cooling, either by vibration or chemical means, leaving behind the complex internal pipe structures.

- Quality requirements: Any minor defect in the mold—uneven density, insufficient strength, or dimensional deviation—can directly lead to scrapping engine parts worth tens of thousands of dollars. Therefore, the reliability of upstream sand preparation systems is held to extremely high standards.

⚙️ The “Invisible Threat” in Sand Preparation Systems: High-Pressure Blowing and Dust Intrusion

In the customer’s production workshop, the automated sand preparation units responsible for mixing, transporting, and storing precision sand are core equipment. These systems not only mix sand and resin precisely but also transport the mixture to each molding station through complex pipelines and silos.

To improve conveying efficiency, clear residual material, or achieve flowability, the sand preparation system frequently or continuously employs high-pressure pneumatic conveying or pulse blowing mechanisms. This critical automation step becomes the “invisible killer” for conventional level switches.

Microscopic Mechanism of Competitor Rotary Paddle Failures

The customer previously attempted to use low-cost rotary paddle level switches available on the market to detect sand levels in silos or buffer bins. However, these products quickly revealed severe reliability issues, primarily due to insufficient sealing:

Low-Cost Rotary Paddle Reliability Issues: Insufficient Sealing

- “Pump effect” under high pressure: High-pressure air or frequent pressure fluctuations cause slight gaps in the seals (oil seals or gaskets) around the paddle shaft. Fine sand particles (<100 μm) are forced into the level switch’s internal shaft bearing chamber.

- Dust solidification and jamming: Once inside, the sand particles mix with ambient moisture or lubricants from the bearings, forming a hard, abrasive-like compound.

- Mechanical failure: Over time, friction increases dramatically, eventually causing the miniature motor shaft driving the paddle to jam completely. The level switch stops rotating, failing to detect material level and risking motor burnout, resulting in production downtime and reputational damage. In such conditions, level switches must have extremely high sealing performance.

🛠️ Jiwei’s Reliability and Strategic Upgrade

In this harsh environment, Jiwei’s rotary paddle level switches demonstrated outstanding quality and design foresight.

Key Advantages of Jiwei Rotary Paddle Level Switches

- Multi-layer labyrinth sealing: Jiwei’s dual labyrinth sealing isolates the internal motor chamber from the external high-pressure dust environment, preventing dust ingress even under continuous high-pressure pulse blowing.

- High-grade components: Industrial-grade bearings and motors ensure long operational life even with minor dust intrusion.

Thanks to this robust design, Jiwei’s rotary paddle level switches have operated reliably for years on the customer’s sand preparation machines, becoming one of the few long-term dependable level control components.

From “Excellent” to “Outstanding”: Strategic Upgrade to Vibration Rod Technology

Committed to providing worry-free automation solutions, Jiwei proposed upgrading to vibration rod (vibrating rod) level switches to eliminate the inherent wear and maintenance risks of mechanical moving parts.

Disruptive Advantages and Patent Protection

Vibration rod level switches represent a leap in powder level measurement technology, completely eliminating moving mechanical parts and solving the jamming issues of rotary paddles.

- Measurement principle: Piezoelectric crystals drive the probe at a fixed resonance frequency. When sand covers the probe, damping reduces vibration amplitude, triggering an immediate switch signal.

- Dual-rod patented design: Many competitors still use single-rod designs, which are more susceptible to interference and false triggering. Jiwei’s patented dual-rod design provides higher stability and interference resistance, ensuring precise and reliable measurement.

Ultimate Protection and Lifespan

- No bearings or shafts: Eliminates dust intrusion pathways.

- Integrated design with high sealing: High-strength cast housing and advanced welding/sealing achieve IP67 protection, ensuring the switch is dust- and water-tight even in harsh conditions.

- Extended lifespan: With no wear parts and strong environmental resistance, the switches offer virtually unlimited service life, reducing maintenance costs and downtime risks.

📈 Long-Term Value and Strategic Partnership

Upgrading to Jiwei’s vibration rod level switches brings more than just a component replacement—it significantly enhances overall system reliability.

- Empowering equipment manufacturers: Ensures stable operation and lower failure rates for downstream automotive OEMs, enhancing competitiveness.

- Reducing after-sales costs: Eliminates downtime and maintenance caused by switch failures.

- Optimizing production processes: Continuous, reliable sand level signals support uninterrupted supply to mold production, improving efficiency and safety.

This visit by Jiwei engineers not only reinforced trust from years of collaboration on rotary paddle level switches but also provided a future-proof, highly reliable, and efficient solution for the Suzhou automotive precision casting manufacturer’s sand preparation system. Jiwei remains committed to driving automation upgrades for China’s high-end manufacturing industry through innovative technology.