Enhancing Biomass Process Stability with Tube-11 Level Switch

Industry Background

In the modern biomass energy industry, straw has become one of the most important renewable resources used for producing fuel pellets, bioethanol, and biomass power. However, the low bulk density, high impurity content, and complex conveying behavior of straw create major challenges for process stability.

In straw pretreatment systems — including crushing, washing, drying, roasting, cooling, and powdering — level control is critical. Accurate and stable level detection ensures the continuous operation of conveyors, rotary valves, and belt systems, directly affecting production efficiency and safety.

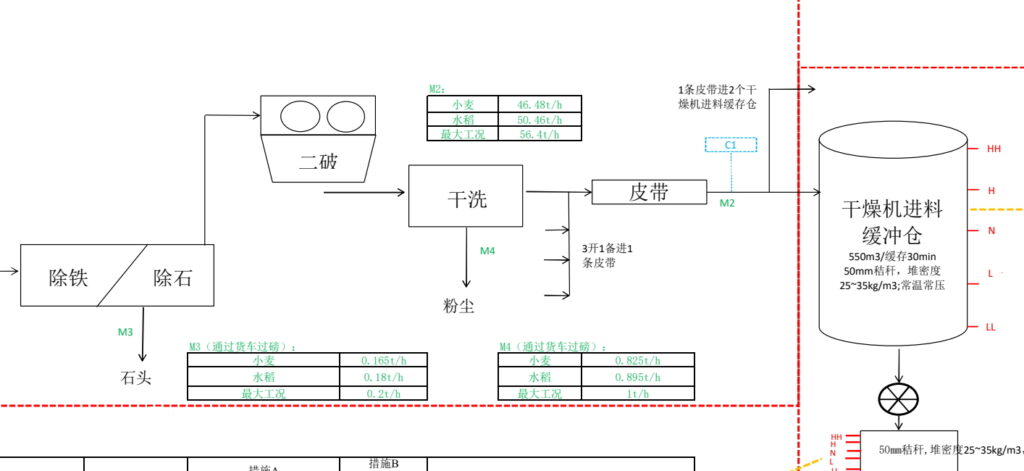

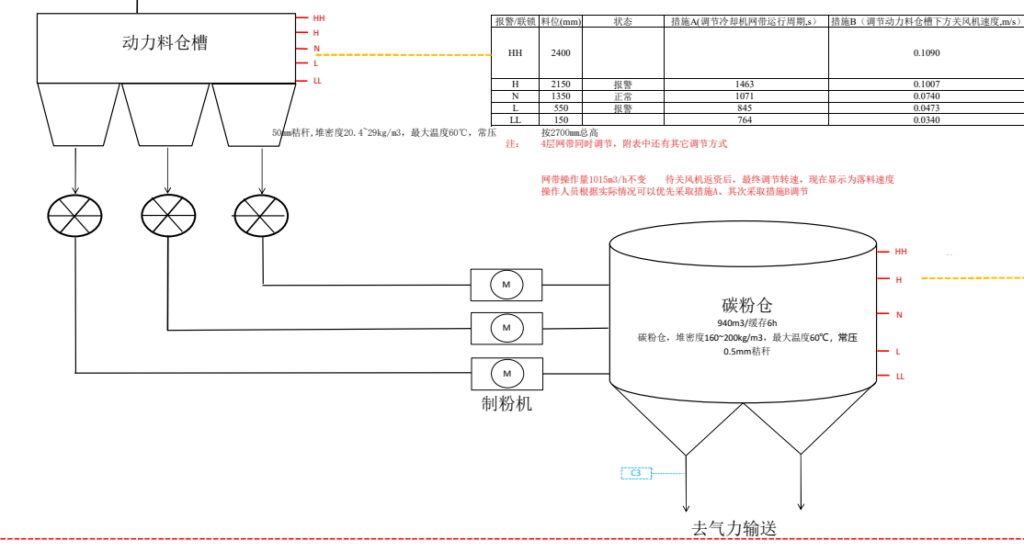

This project was implemented at a large-scale biomass utilization plant in East China, equipped with multiple crushing lines, washing systems, dryers, and roasting machines. The stored material consists mainly of wheat and rice straw, with a bulk density of 20–35 kg/m³ and particle size between 0.5 mm and 150 mm.

Each storage bin (anti-blocking silo, drying buffer bin, roasting bin, cooling bin, and powder bin) required precise level monitoring to enable interlocking control with upstream and downstream processes. However, the previous system — based on capacitive and RF admittance level switches — suffered from frequent false triggering, drift, and maintenance downtime.

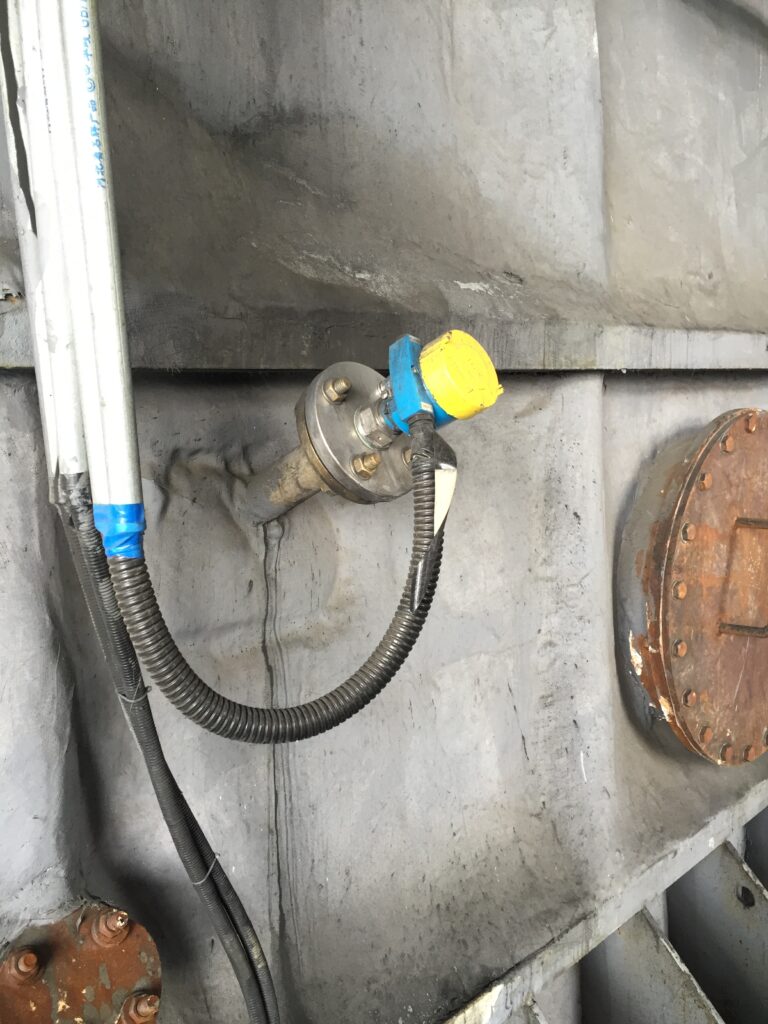

To overcome these issues, the engineering team collaborated with Jiwei Automations, selecting the Tube-11 Vibrating Rod Level Switch as a more stable, reliable, and low-maintenance solution for powder silo monitoring.

Application Challenges

The straw pretreatment process involves variable material conditions and environmental stresses. The team faced several major challenges:

1. Low-Density Powder Characteristics

Straw materials are light, fibrous, and have very low bulk density. Traditional capacitive or admittance-type sensors often fail to detect such materials consistently, leading to missed or delayed level signals.

2. Strong Vibration and Temperature Variation

The equipment operates under continuous vibration (up to 3–5 g acceleration), while process temperatures fluctuate from ambient to 250°C. Many sensors cannot maintain stable operation under such mechanical and thermal stress.

3. Dust and Static Interference

The crushing and drying stages generate heavy dust and static buildup, which interfere with electrical sensors or cause coating on the probes, leading to false alarms.

4. High Interlocking Response Requirements

Each silo has multiple level points (HH, H, L, LL), which directly control the belts, rotary valves, and fans. Any delay or false signal may result in clogging, material loss, or equipment damage.

5. Limited Installation Space

Some silos, especially anti-blocking hoppers and cooling bins, have restricted internal space. The sensors must be compact, vibration-resistant, and easy to install without structural modifications.

Jiwei Solution — Tube-11 Vibrating Rod Level Switch

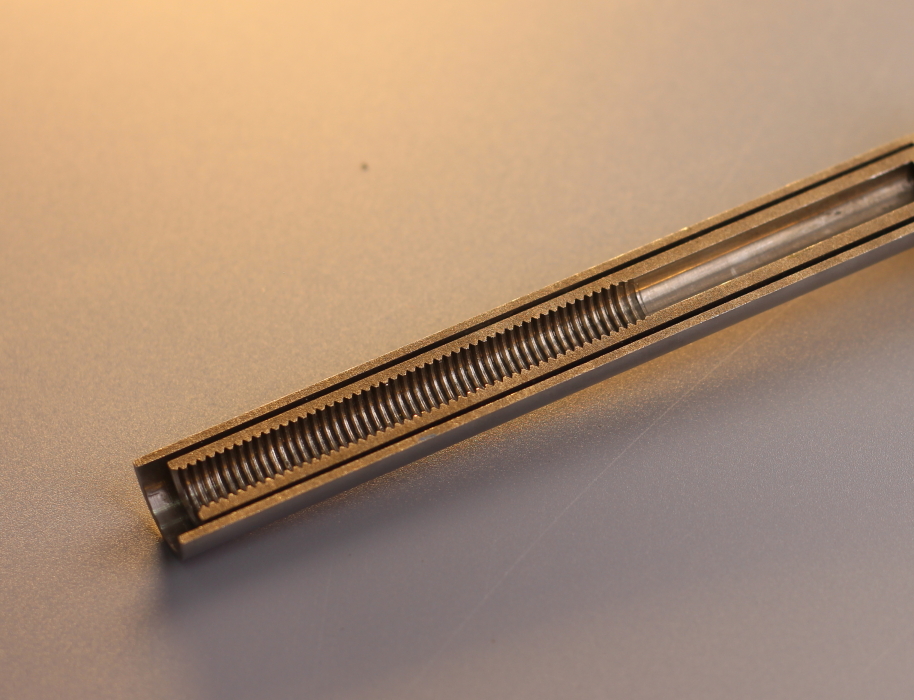

After evaluating the process conditions, Jiwei Automations provided the Tube-11 Vibrating Rod Level Switch as the main sensing element. Designed specifically for powder and granular materials, Tube-11 addresses the above challenges with several key advantages.

Dual-Rod Structure

Unlike single-rod designs, Tube-11 features a dual-tube probe that enhances vibration stability and sensitivity, ensuring reliable response even in lightweight materials with low bulk density.

Vibration and Temperature Resistance

Tube-11 is engineered to operate under vibration acceleration up to 5 g and withstand process temperatures up to 400°C, making it ideal for high-temperature roasting or drying bins.

Dustproof, Maintenance-Free Design

The IP67-rated sealed structure prevents dust intrusion and buildup. The probe surface resists coating and requires no regular cleaning or recalibration.

Media Independence

Performance is unaffected by changes in material moisture, conductivity, or dielectric constant, ensuring consistent switching in variable biomass materials.

These attributes make Tube-11 an ideal replacement for imported powder level switches in biomass and chemical industries.

Implementation and Integration

To achieve complete control and interlocking, Jiwei engineers and the plant’s automation team customized the configuration for each process stage:

1. Anti-Blocking Silos

Each anti-blocking bin (3.5 m × 1.5 m × 1.2 m) was equipped with two Tube-11 switches for high-level (H) and low-level (L) detection.

When material reaches the high-level threshold, the control system reduces conveyor speed; at high-high (HH) level, it automatically stops the upstream crusher feed to prevent blockage.

2. Dryer and Roaster Buffer Bins

In the drying and roasting systems (25–35 kg/m³ bulk density, 250°C maximum), Tube-11 switches monitor material buildup. When reaching HH level, the system halts the screw feeder and rotary valve. LL level triggers low material alarms and automatic refill commands.

3. Cooling and Powder Bins

The cooling bin uses Tube-11 for upper and lower level detection, enabling automatic coordination with cooling belts and air fans. The fine powder bin (160–200 kg/m³ bulk density, ≤60°C) uses Tube-11 to manage mill loading, preventing overfeed.

4. Control Integration

All Tube-11 outputs were connected to the plant’s PLC system, with level signals displayed in real time on the SCADA interface. The system automatically adjusts conveyor and fan speeds based on level status.

5. Field Installation and Testing

Jiwei’s technical engineers traveled on-site to complete installation and commissioning. During testing, Tube-11 showed response time <0.5 s, no false triggers, and stable operation even under continuous vibration and heavy dust for over 800 hours.

Operational Results

After months of continuous operation, the Tube-11 vibrating rod level switches achieved outstanding performance across all process stages.

1. Enhanced System Stability

Level signals remained precise and consistent. Automated interlocks prevented material overflow, underfeed, or clogging, reducing unplanned shutdowns by approximately 40%.

2. Maintenance-Free Operation

Compared to previous capacitive sensors, Tube-11 required no recalibration or cleaning. Maintenance workload was reduced by over 60%, saving both time and labor.

3. Improved Equipment Safety and Lifetime

Fast interlock response prevented overloading of conveyors, rotary valves, and fans. SIL2/3 certification provided additional assurance for safety-critical systems.

4. Significant Cost Savings

Replacing imported level switches reduced system costs by 25–30%. The long service life and maintenance-free design further minimized operational expenses.

5. Positive Customer Feedback

Plant engineers reported that Tube-11 performed exceptionally well even in low-density, high-dust conditions. The device’s consistent performance led to plans for deployment in future drying and pelletizing lines.

Technical Insight

The Tube-11 vibrating rod level switch detects material presence through vibration damping. A piezoelectric crystal drives the probe into resonance. When covered by material, the vibration frequency decreases due to damping, and the electronics convert this change into a switch signal.

Unlike capacitive or RF admittance sensors, Tube-11’s performance is unaffected by material buildup, dielectric variations, or moisture content. The dual-rod structure further stabilizes vibration amplitude and suppresses false signals caused by external vibration or air turbulence.

Its mechanical simplicity and electronic filtering algorithm ensure fast, repeatable switching, even with fibrous biomass or variable particle sizes. For process engineers, this means reliable automation without manual intervention or frequent calibration.

Advantages of Jiwei Tube-11 Vibrating Rod Level Switch

The Tube-11 solution delivered comprehensive advantages for straw pretreatment operations:

Reliability: Stable level signals ensure continuous, safe operation of conveyors, dryers, and fans.

Durability: Withstands vibration, temperature, and dust — ideal for harsh biomass environments.

Maintenance-Free: Self-cleaning and coating-resistant design eliminates regular maintenance.

Cost Efficiency: 25–30% reduction in total system cost compared to imported sensors.

Easy Integration: Compact design with multiple installation options, suitable for retrofits.

This combination of mechanical robustness and electronic intelligence makes Tube-11 a long-term, sustainable solution for powder-level measurement in biomass plants.

Conclusion

Level monitoring in straw pretreatment systems is one of the most demanding applications in biomass process control. The successful implementation of Jiwei Tube-11 Vibrating Rod Level Switches demonstrates how advanced domestic instrumentation can meet and even surpass international standards.

With outstanding vibration resistance, wide temperature tolerance, and international certifications, Tube-11 delivers stable, reliable, and low-maintenance level monitoring under complex process conditions.

By ensuring accurate material control and preventing process interruptions, Jiwei Automations has helped the customer achieve safer, more efficient, and more sustainable operation — proving that high-performance Chinese instruments can stand alongside imported brands in the global biomass industry.