Wastewater and Key Pipeline Level Control — Vibrating Fork Level Switch Application

Project Background

In modern industrial wastewater treatment and odor control systems, level monitoring plays a vital role in ensuring stable and safe operation.

Accurate and reliable liquid level control directly affects the efficiency of wastewater collection, pumping, and discharge systems.

For this project in Zhejiang, the customer required a comprehensive level monitoring solution for multiple pipelines and pump stations, demanding corrosion resistance, signal stability, and long-term reliability under harsh chemical conditions.

Project Requirements

According to the process design, the project presented the following requirements for level detection devices:

- Measurement Environment: Wastewater with chemical residues, high humidity, and potential corrosive components.

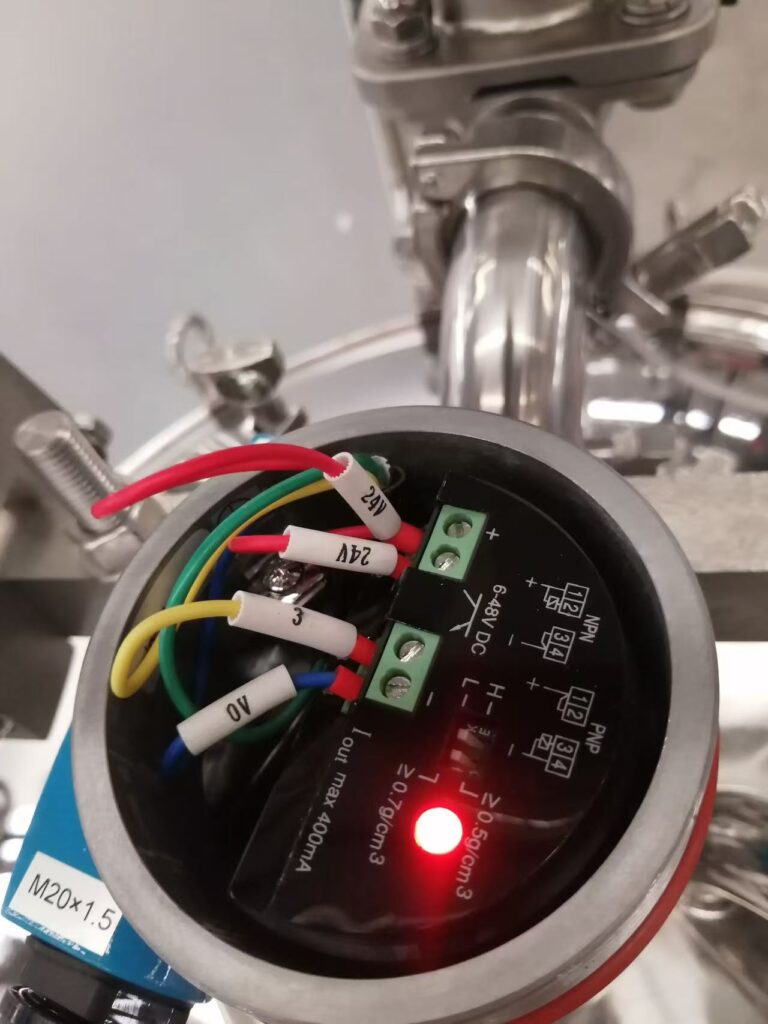

- Signal Output: Must support 4–20mA current signal and NAMUR interface, fully compatible with PLC control systems.

- Material and Durability: Devices must withstand long-term immersion in wastewater and chemical media.

- Explosion Protection: Compliance with explosion-proof standards for use in hazardous industrial zones.

- Maintenance Demand: Instruments should remain stable over years of operation with minimal maintenance.

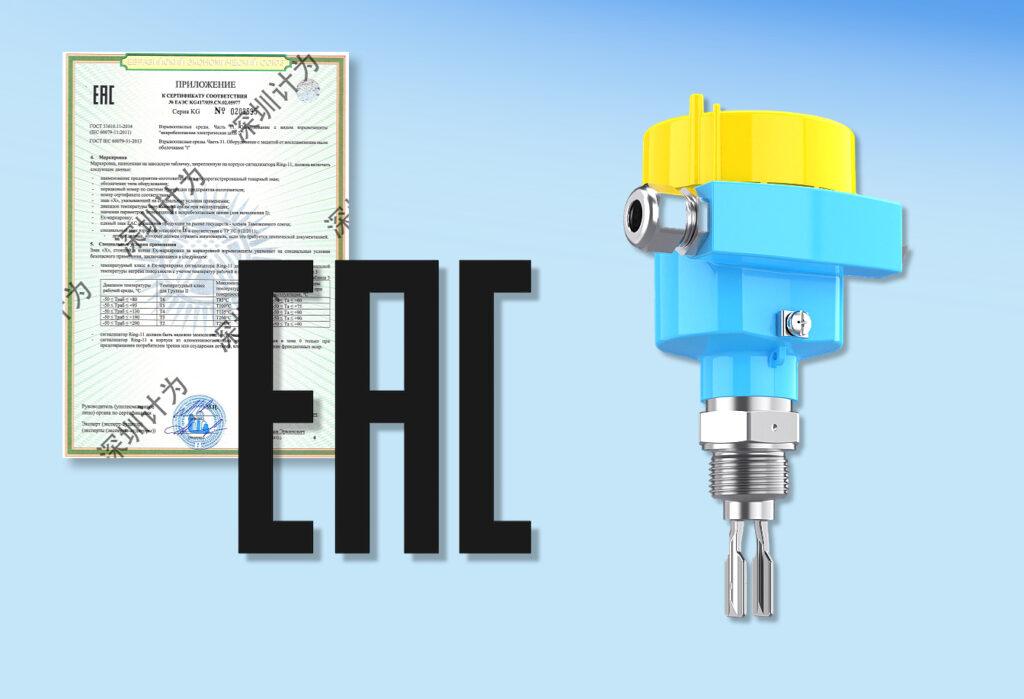

Solution — Jiwei Ring-11 Vibrating Fork Level Switch

After site inspection and technical evaluation, Jiwei Automation provided a complete level monitoring solution based on the Ring-11 vibrating fork level switch.

The Ring-11 is designed for liquid level detection in industrial pipelines and tanks, especially suitable for chemical and wastewater applications where reliability and corrosion resistance are critical.

Key Features

- Full Metal 316L Stainless Steel Construction

The switch body and probe are made from corrosion-resistant stainless steel 316L, with optional Hastelloy or PFA-coated versions.

This ensures durability far beyond 304 stainless steel, even in long-term contact with wastewater or chemical media. - Compact Short Fork Design

Enables easy installation in narrow pipelines (DN50–DN80) or small tanks, while maintaining high sensitivity for liquids with low density, such as methanol or light industrial solvents. - High Signal Reliability

The Ring-11 provides stable and interference-free output, ensuring accurate level detection even under flow turbulence or vibration.

It features NAMUR, relay, and 8/16mA output options, supporting flexible connection with PLC or DCS systems. - Explosion-Proof and SIL Safety Certified

Certified for Ex ia IIC T6 Ga explosion-proof protection, and SIL functional safety approved, the device offers secure operation even in hazardous environments with flammable liquids or gases. - Maintenance-Free Operation

The solid-state design has no moving parts, preventing mechanical wear or drift, and guaranteeing years of stable service.

Installation Overview

The installation process was fully managed by Jiwei’s technical team to ensure perfect integration with the site’s control logic and process flow.

Pipeline Installation

Models RL201, RL203, RL301, RL303 were installed on DN50 and DN80 pipelines, with a 150mm insertion depth.

These switches continuously monitor the flow status within the pipes and detect abnormalities such as air presence or blockage in real time.

Pump Station Control

Units RL401, RL403, RL404, RL501, RL503, and RL504 were installed in key pump station pipelines.

Connected to the PLC control system, they provide automatic pump start/stop control based on level signals, enhancing safety and energy efficiency.

Anti-Corrosion Design

For pipelines exposed to highly corrosive wastewater or chemical media, Ring-11 switches with PTFE-lined housings and extended cable designs were used.

This configuration ensures stable operation, long service life, and minimal maintenance under aggressive conditions.

Commissioning and Testing

During commissioning, Jiwei’s technical team focused on validating signal stability and PLC integration performance.

First, all switches were connected to the PLC through 4–20mA output signals to monitor real-time response to level changes and verify pump start/stop logic synchronization.

Next, simulated abnormal pipeline conditions—such as sudden level drops or flow interruptions—were performed to confirm that the switches could instantly trigger alarm signals and activate system safety interlocks.

Finally, a 24-hour continuous operation test demonstrated signal stability with no drift or false triggering.

Pump station control logic operated precisely, confirming the reliability and consistency of the entire monitoring system under actual process conditions.

Operational Benefits

After installation and continuous operation, the Ring-11 switches have shown outstanding performance across all monitored points:

- High Reliability: No false alarms or signal failures reported after over 6 months of continuous use.

- Corrosion Resistance: Stable operation in wastewater with high chemical content and fluctuating pH levels.

- Maintenance-Free: Operators report no need for recalibration or cleaning, significantly reducing maintenance workload.

- System Safety: Automatic interlock response prevents pump dry-run and ensures safe process control.

By leveraging Jiwei’s Ring-11 vibrating fork technology, the project has achieved stable and intelligent level monitoring across all wastewater and chemical pipelines, supporting long-term system safety and efficiency.

Customer Feedback

“Since we replaced the traditional float switches with Jiwei’s Ring-11, signal stability has been exceptional.

The compact design fits perfectly in our DN50 chemical pipelines, and the corrosion resistance is impressive.

The automatic pump control now runs smoothly without manual intervention.”

This feedback reflects Jiwei’s continuous pursuit of reliability, precision, and safety in industrial automation.

Conclusion

The successful application of Jiwei Ring-11 vibrating fork level switch in wastewater and odor control project marks another milestone in industrial process automation.

With its robust materials, intelligent output options, and verified safety certifications (EAC, 3C, SIL), Ring-11 ensures reliable liquid level detection across wastewater, chemical, and pharmaceutical industries.

Its proven stability and minimal maintenance requirements make it the ideal choice for continuous and safe operation in challenging environments.