Jiwei Stainless-Steel Vibrating Fork Level Switches Ensure Stable Ballast Tank Monitoring in the Persian Gulf

1. Project Background

In the Persian Gulf region, a shipowner building a new bulk carrier required reliable level control for its ballast water tanks to ensure vessel stability and navigation safety. The Gulf’s high salinity, humidity, and intense solar exposure accelerate corrosion, making the environment particularly challenging for level measurement equipment.

During operation, the shipowner needed to:

- Monitor ballast tank levels in real time to maintain draft and vessel stability

- Prevent abnormal levels that could cause listing or tank overflow

- Ensure long-term reliable operation under harsh marine conditions

- Reduce manual inspections and improve crew efficiency

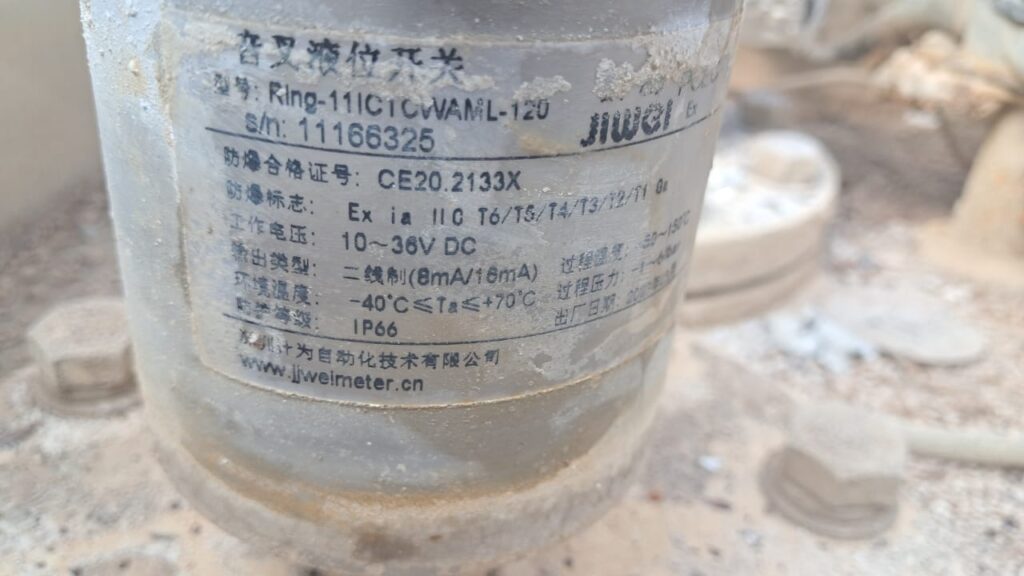

Traditional float-type or guided wave radar level devices often fail in high-salinity seawater and vibrating tank conditions, leading to signal drift or malfunction. After technical evaluation, the shipowner selected stainless-steel vibrating fork level switches from Shenzhen Jiwei Automations Ltd. as the monitoring solution.

2. Selection Reasons

1. Corrosion-resistant stainless-steel housing

Ballast tanks are continuously filled with seawater containing high salinity, humidity, and marine organisms. Jiwei’s vibrating fork switches use 316L stainless-steel housings and FKM/PTFE seals, allowing long-term operation in seawater immersion and salt-mist environments without oxidation or corrosion, ensuring stable signal output.

2. Vibrating fork principle suitable for seawater

Seawater is conductive and often contains bubbles or foam. When the liquid covers the vibrating fork, vibration stops, generating a switch output. Compared with float or guided-wave radar technologies, the vibrating fork has stronger immunity to bubbles, turbulence, and foam, ensuring stable detection.

3. High protection rating for tank interiors

With IP66/IP68 protection, the switch withstands high humidity, water exposure, tank washing, and temporary submersion. Internal electronics remain protected, enabling long-term, maintenance-free service.

4. Long service life and low maintenance

Ballast tanks cannot be frequently accessed during voyages. Jiwei’s vibrating fork switches use corrosion-resistant materials and a robust mechanical structure, delivering service life 5–8 years longer than typical market alternatives.

Notably, Jiwei vibrating fork switches have operated 13 years without failure across 105 units in a Tenglong Aromatics installation—an example of true “install and forget” reliability.

3. Installation Environment & Design

1. Installation Positions

The switch was installed at tank-top and sidewall interfaces, ensuring detection from low level to full tank.

- Top installation reliably indicates high level and overfill protection

- Side installation provides low-level signaling and pump protection

All positions were selected based on CFD analysis or field experience to avoid turbulence and bubble zones, ensuring stable vibration signals.

Signals are integrated into the vessel’s PLC/DCS system, enabling automatic pump interlocks, overfill alarms, and ballast mode switching. After installation, the vessel achieved long-cycle, low-maintenance level monitoring suitable for long-distance voyages.

2. Interfaces and Sealing

Jiwei provides both threaded (G/NPT/Metric) and flanged (DN50–DN100) options:

- Threaded: simple installation, ideal for small or retrofitted tanks

- Flanged: stronger under vibration and pressure; ideal for large-capacity tanks

All devices use FKM/PTFE dual sealing, maintaining reliable water-tightness under salt-mist, humidity, and pressure fluctuations. Before commissioning, technicians conducted low-pressure leak tests to verify sealing integrity.

4. Application Performance & Customer Feedback

1. Stable and reliable level monitoring

The vibrating fork responds to level changes within milliseconds and displays real-time high/low/pump-protection signals on the PLC/DCS screen. Crew members no longer need frequent field checks.

Compared with float systems, the vibrating fork offers superior anti-interference performance in seawater environments.

2. Improved navigation safety

Ballast level directly affects vessel trim and stability. Jiwei’s switch triggers alarms and interlocks immediately when liquid reaches preset thresholds, reducing risks associated with overfill or insufficient ballast. This enables proactive, efficient ballast management.

3. Reduced maintenance cost

The 316L fork and FKM/PTFE seals resist corrosion, fouling, and wear. No disassembly or frequent cleaning is needed. Crew only perform visual checks, significantly reducing maintenance workload and spare part consumption. Shipowners reported 5–8 years longer life compared with traditional devices.

4. Adaptation to harsh marine environments

With strong resistance to humidity, salt spray, shock, and vibration, the switch maintains long-term stability. In multiple fleets, Jiwei vibrating fork switches have shown zero failure performance—becoming a true “install and forget” device.

Customer Feedback

“Since using Jiwei stainless-steel vibrating fork switches, our ballast tank level monitoring has become more reliable and stable. Inspection workload has decreased, maintenance is easier, and navigation safety has improved significantly.”

5. Conclusion

Jiwei stainless-steel vibrating fork level switches have proven their reliability and adaptability in ballast water tank applications across the Persian Gulf. Despite high temperatures, salinity, humidity, and long-duration voyages, they maintain stable vibration characteristics and accurate level signaling without interference from turbulence, bubbles, or deposits.

With real-time monitoring, fast alarming, and automatic interlocks, the ballast system gains greater operational control and safety margins. Shipowners report enhanced ballast management efficiency and significantly extended service life, providing long-term economic value.

This case demonstrates that Jiwei stainless-steel vibrating fork switches are a dependable solution for ballast tank level monitoring in harsh marine environments and demanding vessel operations.