Radar Level Meters for Precise Resin Tank Level Monitoring in Russian Chemical Plant

In high-viscosity resin storage tanks, traditional level measurement devices often suffer from adhesion, foam, or steam interference, leading to unstable readings. A chemical plant in western Russia adopted the Jiwei PRO series radar level meter to achieve continuous level monitoring, improved accuracy, and automated management. This case shares the technical selection, application results, and customer feedback to provide reference for industry peers.

Why Traditional Level Meters Fail in Resin Storage Tanks

The plant produces high-performance resins used in construction, coatings, and composite materials. During production:

- Tank levels change frequently, and the liquid is highly viscous.

- Process temperatures range from -40°C to 130°C.

- Container pressures reach -1 to 6 bar.

Conventional float or guided-wave radar level meters often fail under high viscosity, steam, or foaming conditions, resulting in:

- Low measurement accuracy and unstable level data.

- Frequent manual inspections and reduced production efficiency.

- Increased risk of level abnormalities, overflow, and safety hazards.

The plant therefore required a high-precision, interference-resistant, high-temperature and high-pressure compatible continuous level measurement solution.

Technical Highlights of the PRO Series Radar Level Meter

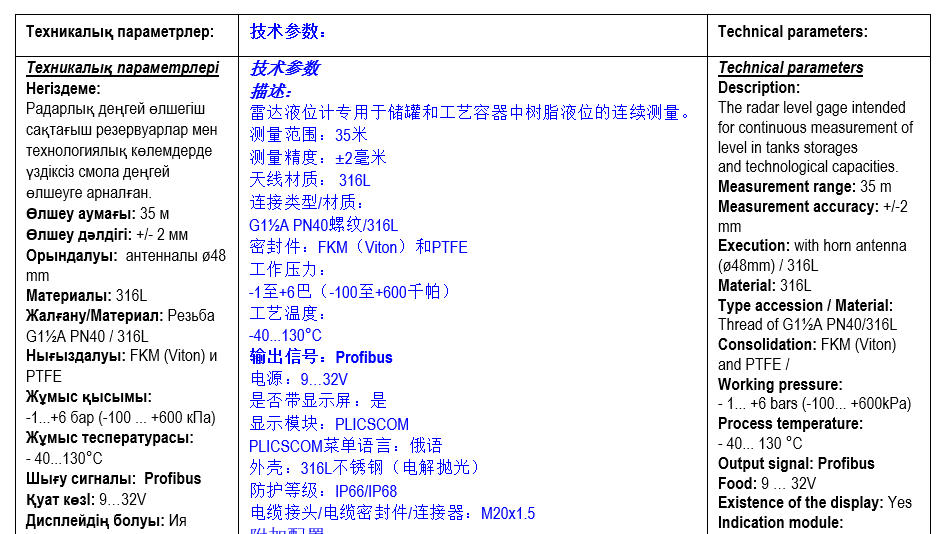

Based on the plant’s process conditions, Jiwei recommended the PRO series JWrada-35 radar level meter. Key technical parameters:

| Parameter | Description |

|---|---|

| Measuring Range | 35 m |

| Accuracy | ±1 mm |

| Antenna Material | 316L + PFA |

| Connection Type/Material | G1 1/2 A PN40 Thread / 316L |

| Seals | FKM (Viton) & PTFE |

| Process Pressure | -1 to +40 bar |

| Process Temperature | -40 to +220°C |

| Output Signal | 4–20 mA/HART |

| Housing | Aluminum, IP66/IP68 |

| Cable Entry | M20×1.5 |

Field Performance

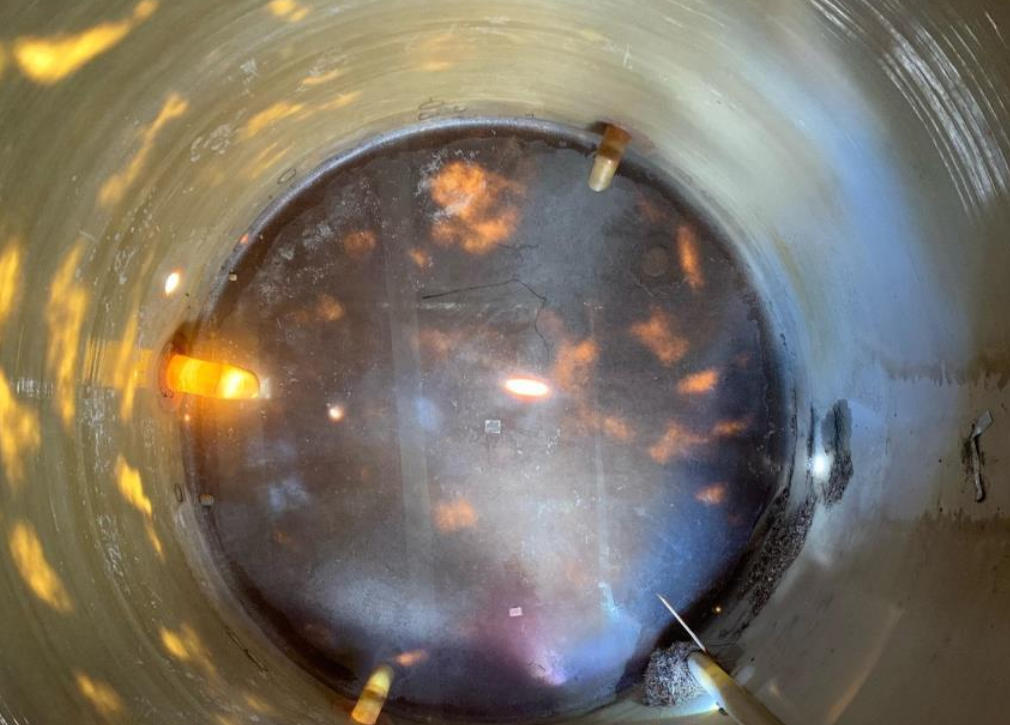

During the first 72 hours of continuous operation, the JWrada-35 performed a full scan in a 27.4 m raw material tank. The echo curves were stable with no interference peaks. Measured level fluctuations ranged from 12.63 m to 18.92 m, with a maximum deviation of ≤0.8 mm compared to the sight glass.

Under dynamic conditions (temperature rising from 68°C to 121°C, pressure increasing from 3.2 bar to 9.6 bar), the measurement signal remained continuous without jumps. During short-term high humidity (relative humidity >95%) in steam washing processes, the antenna surface showed no significant condensation, and echo strength remained 46–52 dB.

Throughout the testing phase, the 4–20 mA/HART output remained stable, with no alarms or data loss. The IP66/IP68 housing maintained excellent sealing even under continuous water spray conditions.

Installation and Commissioning Process

The PRO series JWrada-35 was installed at the top of the tank using a G1 1/2 A threaded connection with a 76 mm antenna. Due to high temperature and periodic pressure fluctuations, the installation and commissioning were confirmed by process, safety, and instrumentation personnel. Key steps included:

Interface Sealing Check

Before installation, threads and seal cavities were cleaned, and FKM/PTFE dual seals were inspected for dents, burrs, or deformation. A low-pressure leak test ensured no oil seepage or air bubbles, providing reliable sealing for operation.

Vertical Antenna Installation

To ensure complete radar wave paths, the antenna was aligned vertically within 1° using a level and positioning fixture, preventing signal weakening or multiple echo overlap and improving echo signal-to-noise ratio.

4–20 mA/HART Connection to PLC/DCS

After wiring, engineers tested analog and digital HART signals in the control room. Loop resistance, supply voltage, and signal fluctuation were all within specifications. HART readings matched the local display, enabling real-time remote monitoring, historical trend recording, and alarm interlocks.

Parameter Setup and Calibration

Using the PLICSCOM module, range, upper/lower limits, dielectric constant, and empty tank calibration points were configured. Static echo curves were recorded to confirm the main echo peak and eliminate false echoes. Blind zone compensation was applied based on tank structure.

Field Testing

During commissioning, empty, half-full, and full tank checks were performed. As the level rose slowly, echo curves followed steadily without jumps or missing signals. Even during rapid humidity increase from steam injection, output remained continuous, and the antenna surface stayed clean. The level error compared to the sight glass remained below ±1 mm.

After full commissioning, JWrada-35 continuously monitored for 72 hours, providing smooth, timely level curves. Operators confirmed that high temperature and pressure fluctuations had minimal impact on measurement stability, and control room trends updated without drift.

Application Results and Benefits

Stable and Reliable Measurement

Level signals that previously drifted due to heating, stirring, or viscosity changes now remain stable all day. Engineers can adjust feed rates and tank pressure with confidence, relying on data rather than experience.

Improved Production Efficiency

Automation enables fixed schedules for feeding, level control, and discharge. Single-tank feed cycles shortened by 8–15 minutes on average, as level signals respond promptly and the control system acts automatically. Manual level checks are largely eliminated.

Reduced Maintenance Costs

Radar meters do not contact the material, avoiding resin buildup. Cleaning frequency is greatly reduced, and monthly downtime for probe cleaning is no longer required.

Enhanced Safety

The meter captures rapid level changes, providing early DCS alarms for high/low level conditions, especially useful during night shifts or holidays.

Strong Adaptability to Harsh Conditions

The IP66/IP68 housing withstands condensation, steam, chemical gases, and high humidity. Continuous operation has been achieved without interruption, even after multiple tank cleanings and high-temperature steam tests.

Conclusion

The Jiwei PRO series radar level meter successfully addressed the challenges of high-viscosity resin storage tanks in a Russian chemical plant, including low measurement accuracy, interference, and high maintenance. It significantly improves production efficiency, safety, and process automation. For similar industrial environments, the PRO series is an ideal solution for reliable continuous level monitoring.