The Difference Between SPST and DPDT Relay Contacts (Industrial Automation Context)

In industrial automation and process control systems, selecting the right relay contact type is critical for system stability, reliability, and future scalability. In liquid‑level, pressure, temperature, and other sensing instruments, relays are a key interface converting sensing signals into control commands.

Among relay output configurations, Single‑Pole Single‑Throw (SPST) and Double‑Pole Double‑Throw (DPDT) are widely used. Their structural and functional differences profoundly affect wiring logic, alarm schemes, and system redundancy. Understanding these relay types helps engineers and buyers make more informed decisions.

1. Definitions & Structural Differences

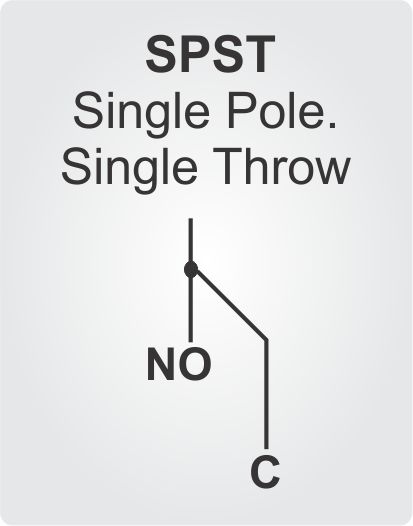

SPST (Single Pole Single Throw)

An SPST relay has one input terminal and one output terminal, functioning simply as an on/off switch. It appears in two forms:

- NO (Normally Open): circuit closed when relay energizes

- NC (Normally Closed): circuit open when relay energizes

Ideal for single‑action control, like basic alarms or pump start/stop logic.

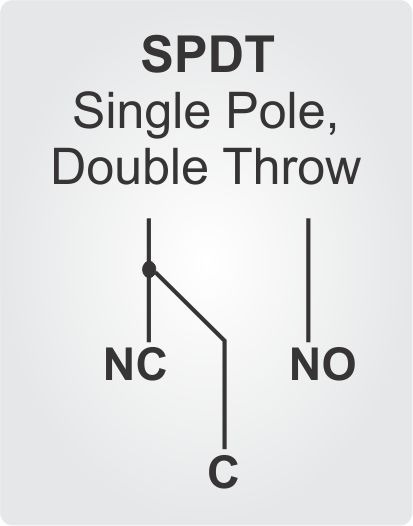

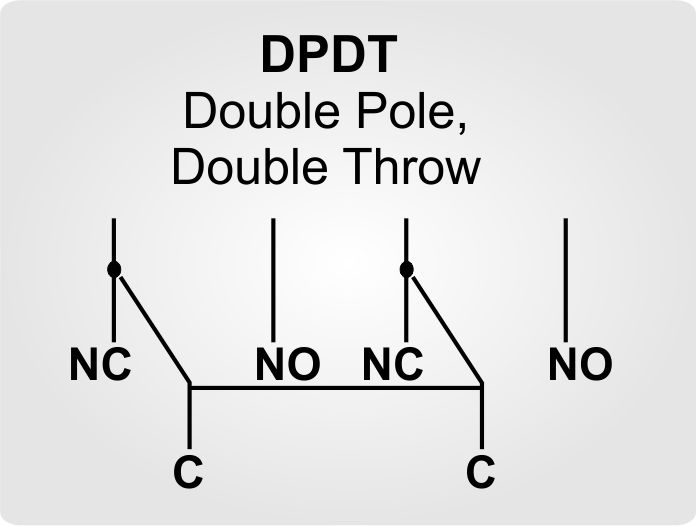

DPDT (Double Pole Double Throw)

A DPDT relay is effectively two SPDT switches activated together. It has two independent input (COM) terminals, each switching between separate NO and NC contacts. In total, DPDT relays provide two fully isolated circuits with selectable outputs .

This makes DPDT relays versatile – perfect for driving two circuits simultaneously or providing redundant signals.

2. Feature Comparison

| Feature | SPST | DPDT |

|---|---|---|

| Poles / Throws | 1P1T (one input, one output) | 2P2T (two independent SPDT circuits) |

| Output Circuits | Single | Dual, isolated |

| Switching Capability | Only open or close | Switch between two states for each pole |

| Flexibility | Low | High; supports multi‑path logic |

| Redundancy | None | Built‑in dual path backup |

| Typical Use | Simple alarm, ON/OFF control | Simultaneous alarm + control, redundancy |

| Cost | Lower | Slightly higher, but offers more value |

SPDT vs DPDT explained: SPDT allows switching one input between NO and NC outputs; DPDT does this for two inputs simultaneously.

3. Why DPDT Is Preferred in Liquid-Level Applications

Take the Ring‑11 tuning fork level switch as an example. This high‑performance liquid‑level sensor features built‑in DPDT relay outputs, enabling dual-channel logic:

- Channel 1 (COM1, NO1, NC1): Drives on-site audible/visual alarms when liquid level exceeds threshold

- Channel 2 (COM2, NO2, NC2): Sends signal to PLC or DCS, triggering automatic shut-off or pump control

Benefits include:

- Redundant control pathways

- Simultaneous local and remote signals

- Selectable NO or NC logic per channel

- Reduced wiring and hardware complexity

Compare this to SPST: With SPST you’d only have one control output – no redundancy, no multi‑circuit control.

4. Industry Applications & Benefits

- Fail‑safe signaling: If one circuit fails (e.g., alarm chain), the second still works

- Logic independence: One output can be NO for alarm, the other NC for preventative logic

- Installation simplicity: No need for extra relays to achieve multiple functions

- Scalability: Future system upgrades (adding DCS or remote monitoring) are easier

DPDT relays are widely used in industrial instrumentation for these reasons.

5. Technical Summary: SPST vs DPDT

| Type | Poles | Throws | Circuits Controlled | Ideal Use Cases |

|---|---|---|---|---|

| SPST | 1 | 1 | Single circuit (simple on/off) | Basic alarm, pump ON/OFF |

| SPDT | 1 | 2 | One input toggles between NO and NC | Mode selection, changeover logic |

| DPDT | 2 | 2 each | Two independent SPDT circuits | Redundant logic, dual-output control |

SPDT gives you two options for a single logic; DPDT gives two separate circuits, both switchable. That’s why DPDT is superior in complex control scenarios like liquid‑level automation.

6. Best Practice Recommendations

- Use SPST for ultra‑simple logic when cost is the primary concern

- Use DPDT for applications requiring redundancy, dual control paths, or simultaneous local & remote signals

- Choose a device like Ring‑11 with integrated DPDT contacts to simplify wiring and support complex automation logic without add‑on modules

Understanding SPST and DPDT relay types—and choosing a DPDT‑equipped device such as Ring‑11—ensures your liquid‑level control system is reliable, flexible, and future‑proof.