Differences Between PROFIBUS and PROFINET in Industrial Automation

The differences between PROFIBUS and PROFINET have been a long-standing topic of discussion in the field of industrial automation. Both belong to the IEC standard system established by PI (PROFIBUS & PROFINET International). While they maintain continuity in engineering concepts and configuration methods, they show clear generational differences in communication architecture, physical layer, and system capabilities. PROFIBUS and PROFINET are not competitors; rather, they represent two industrial communication systems developed in different technological eras.

Technical Positioning of PROFINET

PROFINET (Process Field Net) is an industrial Ethernet communication standard introduced by the PI organization in the early 21st century. Its design directly stems from the industry trend of migrating industrial automation systems from traditional fieldbuses to Ethernet architectures. Its core feature is that it is entirely based on the standard Ethernet physical layer.

In terms of standards, PROFINET is built on IEEE 802.3 Ethernet and, for industrial control scenarios, defines real-time communication mechanisms, device models, engineering configuration methods, as well as diagnostic and safety extension specifications at the protocol level.

This allows it to inherit Ethernet advantages in bandwidth, topology, and scalability, while meeting industrial control requirements for determinism and synchronization. Technically, PROFINET is not a simple upgrade of PROFIBUS; it represents a systematic solution provided by PI in the era of industrial Ethernet.

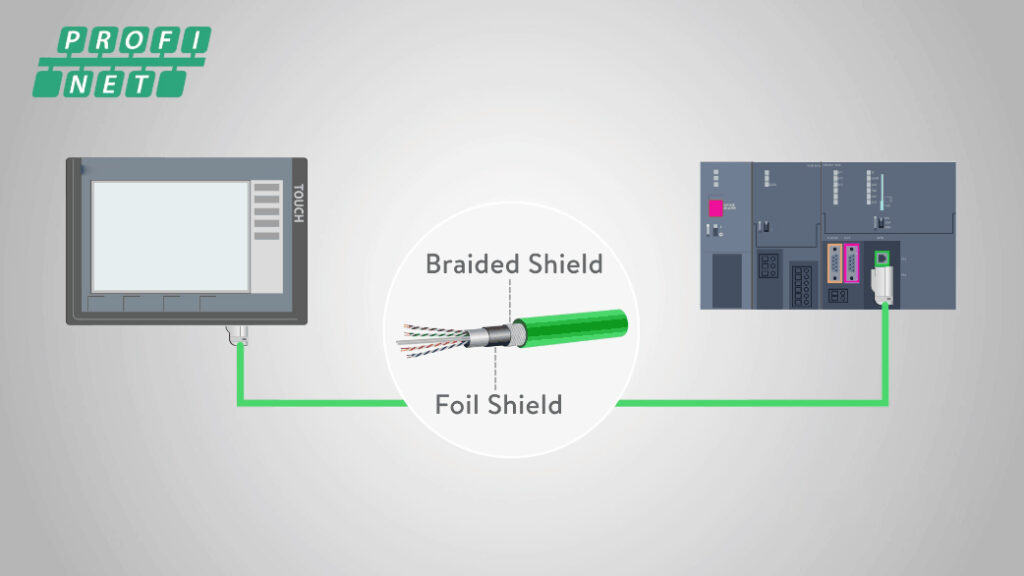

PROFINET uses standard RJ-45 Ethernet interfaces and industrial-grade Ethernet cables. Typical PROFINET cables have green outer jackets. While standard Ethernet cables can sometimes be used, industrial environments generally recommend dedicated PROFINET cables for better shielding and mechanical robustness.

In typical applications, PROFINET operates at 100 Mbit/s with a single-segment copper cable length of up to 100 meters. Thanks to high-speed communication and cycle times below 1 millisecond, PROFINET can support fast I/O refresh and motion control applications.

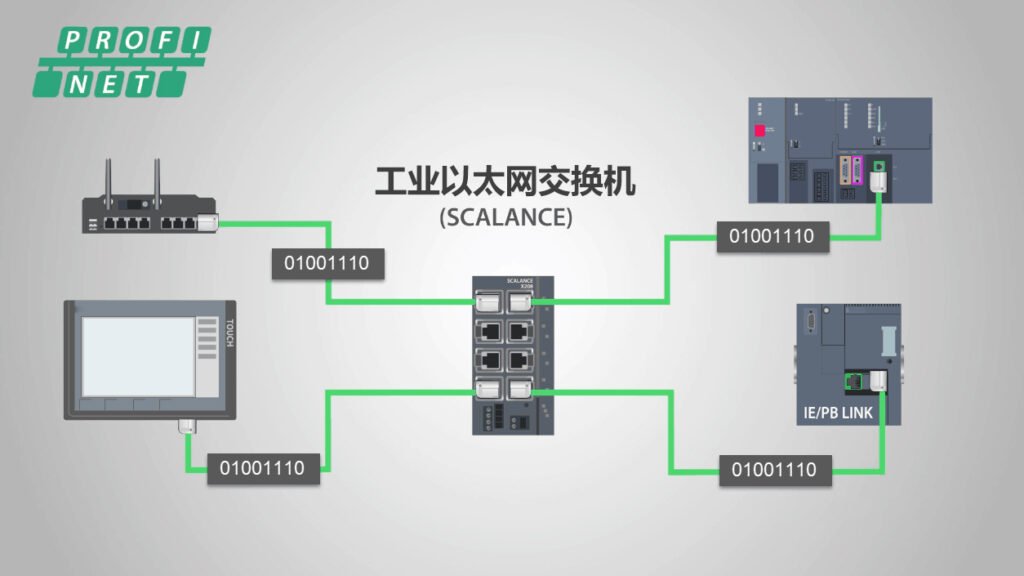

Because it uses standard Ethernet technology, PROFINET networks can be expanded using ordinary Ethernet switches, enabling linear, star, tree, or ring topologies, which is advantageous for system expansion and network planning.

History and Technical System of PROFIBUS

PROFIBUS was officially launched in 1989 and quickly became one of the most widely used fieldbus standards globally during the 1990s. It is a mature and widely validated industrial fieldbus technology, applied in discrete manufacturing, process control, and hybrid automation systems.

Its core goal is to centralize distributed field I/O signals via serial communication, reducing wiring complexity and improving maintainability.

Technically, PROFIBUS is based on RS-485 serial communication, consisting of master devices (such as PLCs, PACs, DCS) and slave devices. Communication is scheduled and controlled by the master. Common devices include drives, motors, remote I/O, sensors, actuators, and field instruments.

PROFIBUS is mainly divided into two types based on application scenarios:

- PROFIBUS DP: for high-speed discrete I/O and drive control

- PROFIBUS PA: using MBP (Manchester Bus Powered) physical layer, suitable for intrinsically safe process automation environments

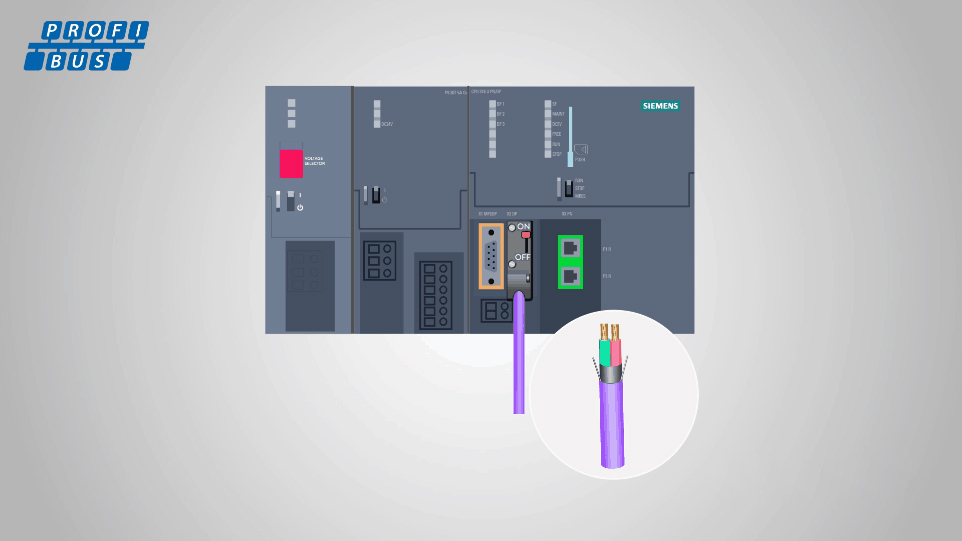

This architecture has long proven highly stable in systems with limited device numbers and data volume. PROFIBUS cables typically have purple outer jackets for high visibility.

Network Topology and Installation

When installing a PROFIBUS network, devices are usually connected in series, a process known as daisy chaining, forming a linear topology for easy device connection. Star or tree topologies can also be used, though less common. PROFIBUS messages can also be transmitted wirelessly, but this requires proprietary wireless modules from the same manufacturer on both ends.

A PROFIBUS network must enable termination resistors at the physical ends. The red DIP switch on the connector controls the termination; only the last device in the network should have it “ON,” while others remain “OFF.” Incorrect termination is a common source of network faults.

Address management requires each device to have a unique address from 1 to 127, allowing a maximum of 127 nodes per network. Addresses can be set via engineering software (STEP7 or TIA Portal) or via DIP switches on the device, depending on device type.

Communication speeds range from 9.6 kbit/s to 12 Mbit/s. Lower speeds allow cable lengths up to 1000 meters, while higher speeds require shorter cable lengths.

Device Identification Differences

PROFINET and PROFIBUS use completely different device identification mechanisms. PROFIBUS relies solely on device addresses, whereas PROFINET devices have three identifiers:

- MAC Address (inherent to the Ethernet device)

- IP Address (for network communication)

- Device Name (unique to PROFINET)

During engineering configuration, automation engineers primarily use device names and IP addresses for assignment and identification, with MAC addresses serving as a lower-level identifier.

Communication Performance and System Scale

- PROFIBUS

- Maximum speed: 12 Mbit/s (commonly 1.5 Mbit/s)

- Maximum message length: 244 bytes

- Address space: up to 126 devices

- PROFINET

- Speeds: 100 Mbit/s, 1 Gbit/s, or higher

- Maximum cyclic data message: 1440 bytes

- Address space: theoretically unlimited (limited by controller resources)

Since PROFINET is fully Ethernet-based, its communication capacity evolves with commercial Ethernet technology, making it a “future-oriented” solution.

From an engineering perspective, the difference is not only speed but also system capability:

- PROFIBUS suits fieldbus systems with relatively fixed device scales and clear communication structures.

- PROFINET provides greater flexibility for high data volumes, multiple nodes, complex topologies, and system integration.

Consequently, both protocols continue to coexist in many industrial plants.

Data Exchange Mechanisms

PROFIBUS uses a master-slave communication model, where all communication is initiated and scheduled by the master, and devices respond only when queried. This structure is clear but has fixed data flow and bandwidth utilization.

PROFINET uses a producer/consumer model, where both controllers and I/O devices can simultaneously provide and consume data, fully leveraging Ethernet full-duplex capabilities. Controllers provide output data and receive input data, while devices also play a bidirectional role, supporting high-volume and multidirectional communication.

Proxy Mechanism and System Integration

Interconnection between networks is common in multi-protocol systems. PROFIBUS relies on gateways for network conversion, while PROFINET introduces a proxy mechanism as an open standard.

PROFINET proxies can support PROFIBUS DP, PROFIBUS PA, AS-i, IO-Link, CANopen, Modbus, HART, Foundation Fieldbus, and other protocols, allowing non-Ethernet devices to integrate into PROFINET systems with unified engineering configuration and diagnostics.

Industry Application and Installed Base

Both technologies have matured ecosystems. As of 2019, there were approximately 60 million PROFIBUS nodes and over 32 million PROFINET nodes installed globally. PROFIBUS has a larger installed base due to its earlier introduction, while PROFINET has continued to grow steadily and dominates newly built systems.

From an investment protection standpoint, the PI standard ensures continuity in engineering tools, device descriptions, and system integration, enabling gradual migration to Ethernet architectures.

Conclusion

PROFIBUS and PROFINET represent industrial communication systems developed in different stages. PROFIBUS laid the foundation for the fieldbus era, while PROFINET expands industrial communication capabilities on Ethernet architectures.

In today’s industrial automation environment, both will coexist for a considerable time, serving industrial systems of different scales and technological stages.