Impact of Bearing Bore Diameter on Mechanical System Reliability

Impact of Bearing Bore Diameter on Mechanical System Reliability

In mechanical systems, rolling bearings are among the most common fundamental components. While standardization is high, many engineering failures—such as bearing overheating, increased vibration, abnormal noise, and reduced service life—are often not due to the bearing itself but are closely related to improper fit between the bearing bore diameter and the shaft.

Although seemingly simple, the bore diameter directly affects installation quality, load transmission, internal clearance, and overall reliability. This article systematically reviews bearing bore diameter and fit issues, providing guidance for design, manufacturing, and maintenance.

1. Definition and Function of Bearing Bore Diameter

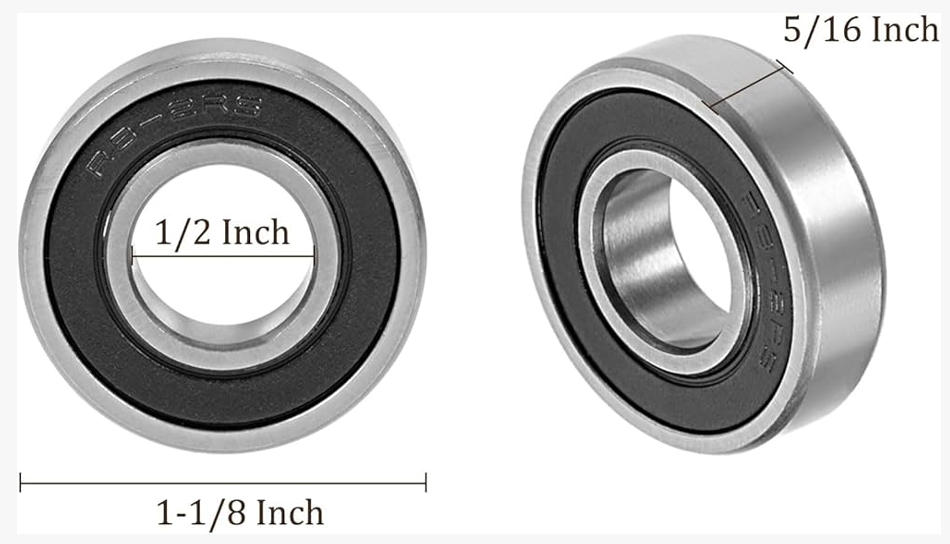

The bearing bore diameter refers to the inner ring hole diameter that fits the shaft, serving as the geometric reference for installation. For example:

- 6205: Bore = 25 mm

- 6308: Bore = 40 mm

- 6010: Bore = 50 mm

The importance of the bore diameter is reflected in three aspects:

- Determines correct installation, including assembly methods, applied force, and reliability.

- Affects fit tightness or looseness, which in turn changes internal operating clearance.

- Influences operational stress, load distribution, geometric stability, and raceway pressure.

In bearing selection, the bore is not just a “dimension” but a fundamental condition for proper assembly and operation.

2. Engineering Principles for Bearing Fit

In standard applications, the inner ring typically uses one of three fits: clearance fit, transition fit, or interference fit. Selection depends on load type, shaft speed, temperature, and installation method.

- Rotating loads on the inner ring: Usually require interference fit.

- Rotating load: Load direction constantly changes relative to the inner ring.

- The inner ring must be firmly fixed on the shaft without relative creep.

- Typical in motors, high-speed spindles, hydraulic pumps, and gear shafts. Loose fit can cause micro-slip, friction wear, and temperature rise.

- Static or light loads: Clearance or transition fit is suitable.

- Static load: Load direction remains constant, such as in conveyor shafts.

- Advantages include easier assembly/disassembly and minimal loss of clearance. Suitable for low-speed shafts or simple rotating devices.

- High-temperature conditions: Fit and internal clearance require special consideration.

- Thermal expansion increases actual interference.

- Prefer larger internal clearance (e.g., C3) and possibly hot-fitting methods.

- Common in dryers, high-temperature fans, and heated rollers.

3. Typical On-Site Symptoms of Improper Fit

- Rapid initial heating:

- Cause: Excessive interference compressing the inner ring, reducing clearance.

- Result: Elastic deformation and poor lubrication film formation.

- Suggestion: Check shaft tolerance and adjust interference; select C3 clearance for high-speed environments.

- Vibration or light whistling:

- Cause: Loose fit, inner ring micro-slip, assembly misalignment, or shaft geometry deviation.

- Suggestion: Use light interference fit, smooth shaft surface, and proper lubrication.

- Early pitting or local spalling:

- Cause: Oval deformation, stress concentration, uneven load.

- Suggestion: Recalculate fit for load, check shaft quality, avoid uneven assembly force.

4. Effect of Bore Fit on Bearing Clearance

Internal clearance is key to operational stability.

- Overly tight fit → reduced effective clearance, higher friction, temperature rise, shorter lifespan.

- Engineering practices:

- High-speed: Use C3 clearance

- High-temperature: Choose larger clearance (C3 or C4)

- Precision: Preload design for high rigidity

5. Bearing Bore Selection Steps

- Determine shaft diameter, tolerance, and surface roughness.

- Identify load type: Rotating → interference, static → clearance/transition.

- Evaluate temperature and speed: High-temp/high-speed → C3 or larger clearance.

- Confirm installation method: cold-fit, hot-fit, or using locating rings.

- Verify bore tolerance per ISO standards to avoid overly tight or loose assembly.

6. Common Engineering Mistakes

- Assuming bearings are interchangeable by model without checking fit and clearance.

- Improper pressing during installation; force must be applied correctly.

- Using standard clearance at high temperature or speed, leading to excessive heat and wear.

- Ignoring shaft and housing geometric errors; roundness and surface finish affect fit.

7. Conclusion

Bearing bore diameter is a critical parameter that, together with proper shaft fit, determines operational status, temperature, vibration, and service life. Correct fit and clearance selection improve reliability and reduce maintenance costs. Engineers should focus on:

- Choosing the right fit for load type

- Selecting appropriate clearance for temperature and speed

- Verifying shaft and housing geometry

- Ensuring proper assembly methods

- Adjusting fit strategy based on operational feedback

By systematically understanding and applying these principles, bearing life can be maximized, and overall mechanical system performance enhanced.