Ethanol Process Level Monitoring – Level Switch & Radar Level Sensor

Industry Background

In ethanol production, accurate liquid level control is critical for fermentation, pH adjustment, and cleaning operations. Process vessels require the addition of acids or bases to adjust pH, while strong alkalis such as sodium hydroxide are used during CIP cleaning. These processes demand strict hygiene standards and high corrosion resistance for any liquid level instrumentation.

Inaccurate level monitoring can lead to overflow, dry-run conditions, or process deviations, resulting in equipment damage, production loss, and safety hazards. Traditional float-type or capacitive level switches are prone to corrosion, signal drift, or build-up when exposed to strong acids, alkalis, and temperature fluctuations, making them unreliable for long-term operation.

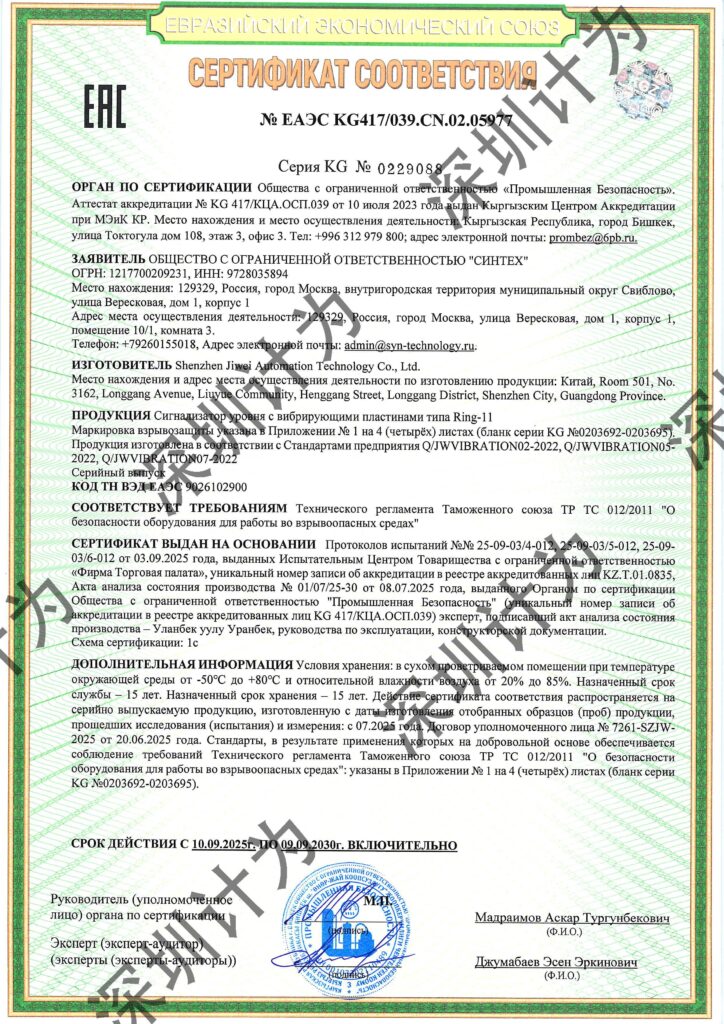

To address these challenges, Jiwei Automations provides Ring-11 tuning fork level switches for point-level detection and overflow protection, paired with JWrada® radar level sensors for continuous level measurement. These instruments withstand temperatures up to 400°C and are certified EAC, 3C, CE, and SIL2/3, ensuring reliable performance in harsh chemical environments.

Project Overview

This project was implemented at a modern ethanol production plant, where continuous monitoring of process vessel liquid levels is required to maintain production stability. The vessels contain acids such as hydrochloric and sulfuric acid, as well as strong alkalis like sodium hydroxide. Operating temperatures range from 20°C to 40°C.

The system must provide both continuous level monitoring and point-level detection for overflow prevention and dry-run protection while ensuring stable chemical dosing and fermentation conditions. The customer previously used imported tuning fork or capacitive level switches but experienced corrosion, signal drift, and high maintenance costs.

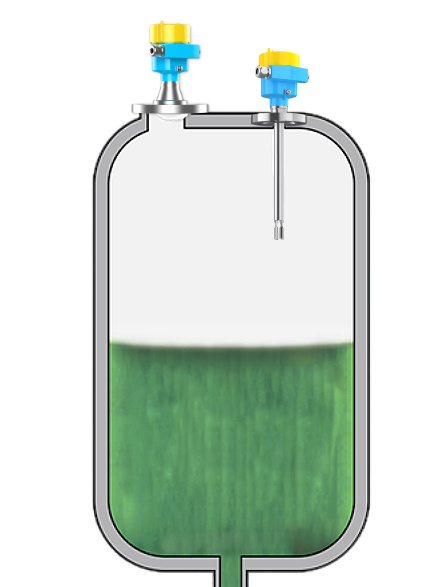

After on-site evaluation, Jiwei Ring-11 tuning fork level switches were selected for critical point-level overflow and dry-run protection, while JWrada® radar level sensors were used for continuous liquid level monitoring, creating a high-temperature, corrosion-resistant, and reliable level measurement solution.

Application Challenges

Ethanol process vessels pose several technical challenges. The acidic and alkaline liquids require extremely corrosion-resistant materials. Certain process steps involve high-temperature cleaning and sterilization, requiring level sensors to withstand up to 400°C. Continuous level monitoring is essential to prevent overflow and dry-run conditions while maintaining stable fermentation and chemical dosing. Hygienic design is also critical to comply with CIP/SIP cleaning standards. Traditional capacitive or admittance-level switches often fail in these demanding conditions, making the combination of Ring-11 level switch and JWrada® radar sensors an optimal solution.

Jiwei Solutions: Ring-11 Level Switch & JWrada® Radar Level Sensor

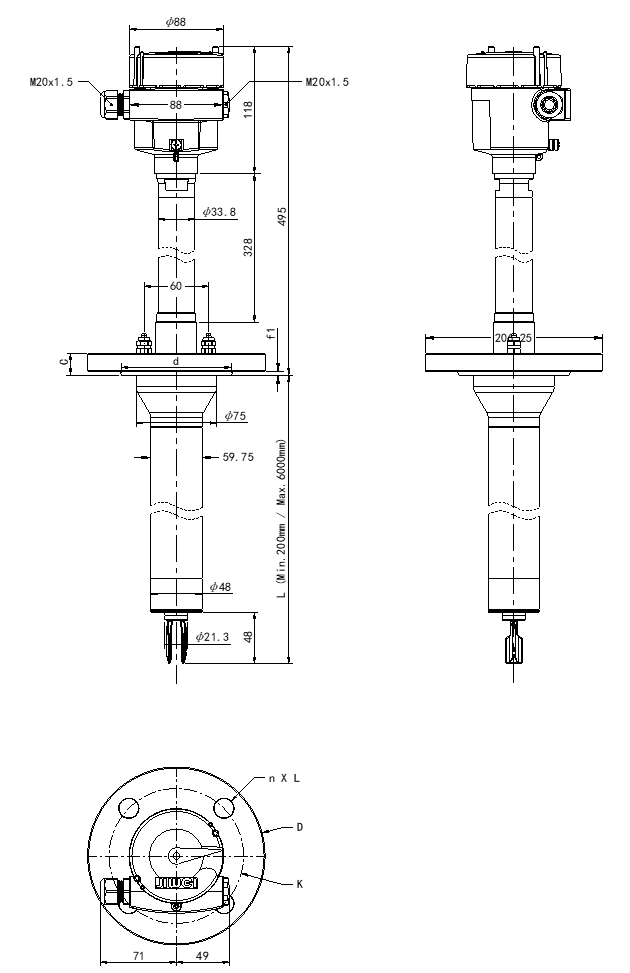

Ring-11 Tuning Fork Level Switch

Application: Point-level detection for overflow protection and dry-run prevention.

Key Features:

- High-Temperature Capability: Operates reliably up to 400°C.

- Corrosion Resistance: Wetted parts made from stainless steel or corrosion-resistant alloys.

- Media Independence: Performance unaffected by acid/base concentration, viscosity, or dielectric constant.

- Compact Design: Suitable for tight spaces and sanitary installations.

- Comprehensive Certifications: EAC, 3C, CE, SIL2/3 for use in safety-critical systems.

Working Principle:

A piezoelectric element excites the fork into vibration. When the fork is submerged, damping reduces its resonant frequency. The integrated electronics detect this frequency shift and output a switch signal, providing reliable overflow or dry-run protection regardless of liquid properties.

JWrada® Radar Level Sensor

Application: Continuous level monitoring in ethanol process vessels.

Key Features:

- Non-Contact Measurement: No direct liquid contact, minimizing corrosion and build-up.

- Corrosion-Resistant Construction: Plastic-encapsulated antenna and stainless-steel housing suitable for strong acids and alkalis.

- High-Temperature Compatibility: Withstands process and cleaning temperatures up to 400°C.

- High Accuracy & Stability: Provides real-time continuous monitoring of liquid levels.

- Safety Certifications: EAC, 3C, CE, SIL2/3, compatible with Safety Instrumented Systems (SIS).

Working Principle:

Radar pulses are emitted towards the liquid surface. The reflected signals are processed to calculate the liquid level. Advanced echo-processing algorithms eliminate interference from foam, steam, or turbulence, ensuring accurate and stable measurement.

Advantages of Jiwei Ring-11 Level Switch & JWrada® Radar Sensors

Jiwei Ring-11 level switch and JWrada® radar sensors together offer a robust and reliable solution for ethanol process vessel monitoring.

Reliability:

The system provides precise liquid level control, ensuring stable fermentation and chemical dosing. Overflow and dry-run conditions are effectively prevented, reducing equipment wear and chemical waste. High-temperature and corrosion-resistant design guarantees long-term stable operation.

Cost Efficiency:

Maintenance-free operation lowers labor and downtime costs. Compact design allows retrofitting existing vessels without major structural changes. International certifications (EAC, 3C, CE, SIL2/3) simplify regulatory compliance and reduce market entry barriers.

Ease of Installation and Use:

Standardized connections allow fast installation. No recalibration is needed when the liquid medium changes. SPST or relay outputs can be directly interfaced with PLCs for automated pump control and liquid level monitoring.

Field Application and Results

In the ethanol plant project, Ring-11 level switches were used for critical point-level overflow protection, while JWrada® radar sensors continuously monitored the vessel levels. Devices were directly interfaced with PLC systems for automated pump control and level management.

Observed Benefits:

- Stable liquid level monitoring without false triggering or drift

- Maintenance frequency reduced by over 50%

- SIL2/3 certification ensures safety system compliance

- Replacement of imported instruments reduced overall system cost by approximately 25–30%

Conclusion

Accurate liquid level monitoring in ethanol process vessels is vital for safety, efficiency, and product quality. Jiwei Ring-11 tuning fork level switches and JWrada® radar level sensors provide high-temperature, corrosion-resistant, and SIL-certified solutions for point and continuous level detection. Their compact design, maintenance-free operation, and international certifications make them an ideal alternative to imported instruments, ensuring long-term safe operation of ethanol process vessels.

References (APA Format)

- Smith, J., & Brown, L. (2021). Advances in ethanol fermentation vessel monitoring: Level measurement techniques. Journal of Industrial Automation, 34(2), 112–124.

- Li, W., Zhang, H., & Chen, X. (2020). High-temperature chemical level measurement in process vessels. Chemical Process Control Review, 15(3), 45–58.

- Jiwei Automations. (2025). Ring-11 & JWrada® Radar Level Sensor Datasheets. Shenzhen: Jiwei Automations.