How a Small Level Switch Ensured Year-Round Stability in a Water Supply System

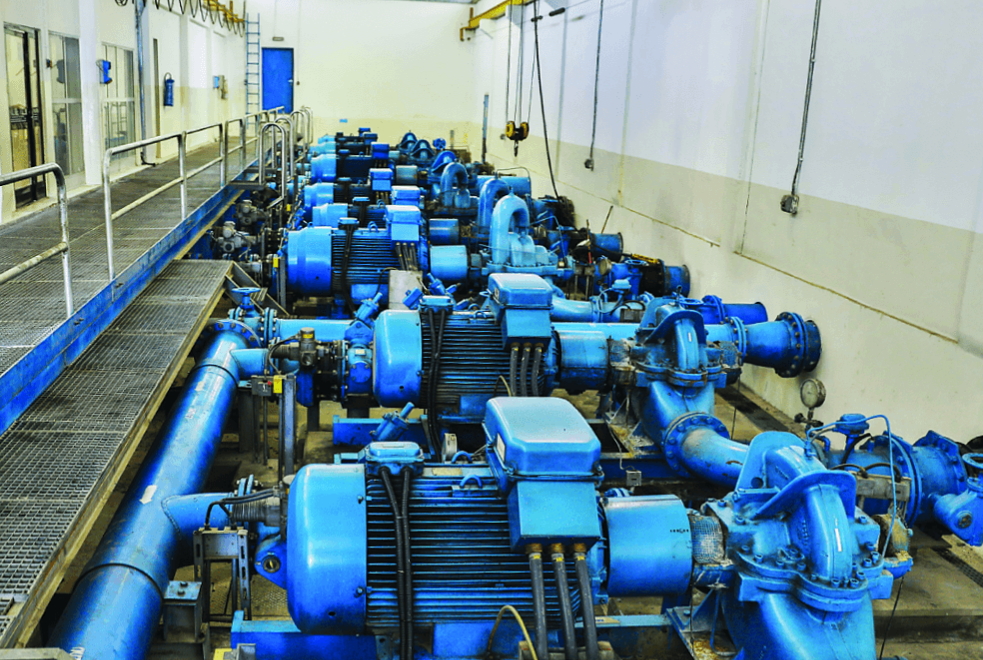

In modern urban water supply systems, the stable operation of water tanks and pumping stations is critical to ensuring a reliable water supply for residential and industrial users. Any failure in level control can result in pump dry-running, water interruptions, or equipment damage. Surprisingly, a small tuning fork level switch proved to be a key solution in a medium-sized city’s water supply project, enabling the system to operate reliably throughout the year and minimizing maintenance challenges.

Project Background

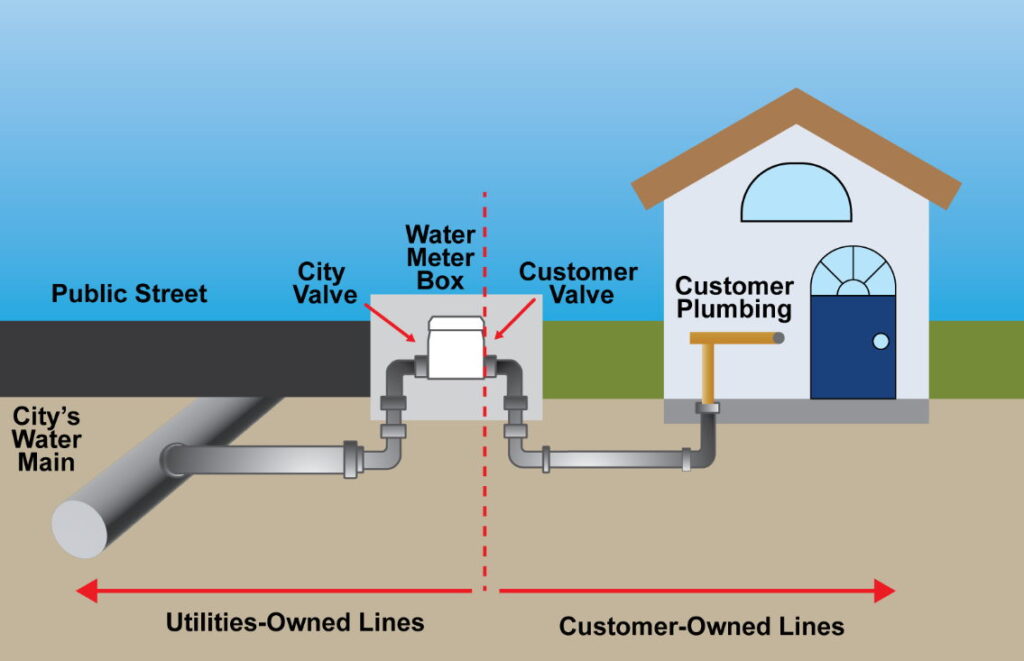

The project is located in an urban area in East China, with the water supply system serving tens of thousands of residents and surrounding industrial zones. The system includes multiple high-rise water tanks and pumping stations with the following characteristics:

- Tank capacities: 50–500 m³

- Medium: potable water

- Operating temperature: 5–35°C

- Installation environment: water tank tops and pump station level chambers

Traditionally, float-type or capacitive level switches were used for water tank level control. However, these devices tend to drift, jam, or fail over long-term operation, leading to pump dry-running or overflow. Urban water systems require extremely high reliability, and maintenance windows are limited. Therefore, a level control solution that is stable, low-maintenance, and easy to install was urgently needed.

Technical Challenges

The engineering team faced several key technical challenges. First, water tank levels fluctuate rapidly, especially during peak consumption hours. Level switches must respond quickly and deliver stable signals to prevent pump dry-running or delayed start/stop, which could affect water supply reliability.

Second, although the medium is potable water, over time small amounts of suspended particles, biofilm, and deposits accumulate. These can cause float switches to jam, drift, or even corrode, and contact-based switches may fail.

Third, some water tanks and pump level chambers have limited space, making the installation of large level instruments difficult and requiring additional brackets or structural modifications.

Finally, the system operates year-round, so devices must be maintenance-free over long periods to minimize downtime and labor costs. These challenges demand a level switch that is reliable, durable, flexible in installation, and compatible with long-term operation in real-world water systems.

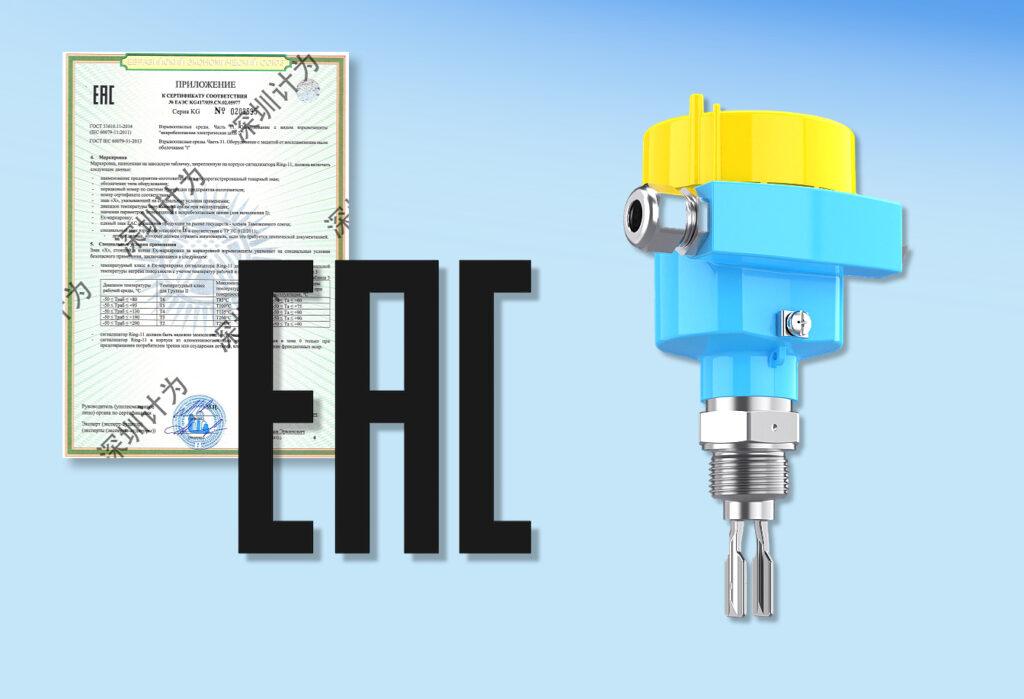

To meet these requirements, the team selected the Jiwei Ring-11 tuning fork level switch for critical point-level detection. Ring-11 is compact, corrosion-resistant, and fully certified (EAC, 3C, CE, SIL2/3), ensuring reliable performance in continuous operation.

Solution

The Ring-11 tuning fork level switch detects liquid levels via piezoelectric vibration. The compact design allows direct mounting on tank sidewalls or pump station level chambers. It provides SPST switch output that can connect directly to PLCs or pump control panels, enabling automated pump start/stop and overflow protection. Its small footprint makes it ideal for confined spaces without requiring additional brackets.

Ring-11 offers exceptional reliability. Its wetted parts are made of stainless steel or corrosion-resistant alloys, allowing long-term contact with water, unaffected by suspended particles or biofilm. The switch responds in under 0.5 seconds, ensuring fast and accurate detection even during rapid level fluctuations, which prevents pump dry-running or overflow. SIL2/3 certification allows integration into Safety Instrumented Systems (SIS) for safety-critical applications.

By connecting Ring-11 to the PLC system, it provides automated level management: pumps start at low-level triggers and stop at high-level triggers, while remote alarms can be sent for centralized monitoring.

Implementation and Operational Results

During implementation, the engineering team assessed each water tank and pump station. Ring-11 was installed at high and low-level points in each tank. Installation was straightforward, using standard threaded connections without structural modification. After integration with PLCs, the system underwent testing and trial operation.

The results were impressive. Level signals remained stable even during rapid water level fluctuations at peak demand times, with no false triggers or signal drift. Over one year of continuous operation, the water supply system remained fully stable. The maintenance-free design reduced maintenance workload by over 50%, lowering both labor and downtime costs. SIL2/3 certification ensured compliance with safety system standards.

Ring-11’s corrosion and water quality resistance eliminated pump dry-running and overflow risks. Its compact design and certification also made it an ideal replacement for imported level switches, reducing system costs by approximately 25–30%.

Technical Analysis

The Ring-11 tuning fork level switch works by detecting frequency changes in the fork’s vibration. When the fork is submerged, liquid damping reduces the vibration frequency, which the internal electronics detect and convert into a switch signal. Unlike float or capacitive switches, the Ring-11 has no mechanical contact, eliminating drift or jamming issues.

This technology is suitable not only for potable water but also for liquids with minor suspended particles or biofilm, delivering stable and reliable signals. When connected to a PLC or control panel, Ring-11 enables automated pump control, overflow protection, and remote alarm functions, supporting fully unattended operation year-round.

Ring-11 also features high immunity to environmental interference; minor changes in water temperature or quality do not affect switch operation. Its compact form factor allows installation in confined tanks or level chambers without additional hardware.

Advantages of Ring-11 Tuning Fork Level Switch

The application of Ring-11 in water supply systems demonstrates multiple advantages:

- Reliability: Continuous operation with no false triggers or signal drift; significantly reduces pump dry-running and overflow risks.

- Durability: Full stainless steel probe and corrosion-resistant materials handle varying water qualities; maintenance-free design reduces labor.

- Cost Efficiency: Replaces imported instruments, lowers system construction and maintenance costs, and reduces downtime losses.

- Easy Integration: Standardized connections enable fast installation; SPST output can be connected directly to PLCs for automated pump control and remote monitoring.

This case illustrates how a small tuning fork level switch can play a decisive role in critical water supply systems, ensuring reliable operation throughout the year.

Conclusion

Reliable liquid level monitoring is less about complex instruments and more about stability, durability, easy installation, and low maintenance. Jiwei Ring-11 tuning fork level switches provide a high-performance, year-round solution for automated water supply control. They ensure pump and tank level management, improve system safety and efficiency, and offer a cost-effective alternative to imported instruments.

This solution is not limited to urban water supply systems; it can also be applied in industrial water treatment, firefighting tanks, and domestic wastewater systems, highlighting the broad applicability of tuning fork level switches in industrial automation.