Waste-to-Energy Level Measurement Solutions: Selecting the Right Point Level Switches for Safe and Efficient Operation

Driven by global energy transition and environmental policies, Waste-to-Energy (WtE) has become a key approach for urban solid waste management and energy recovery. Compared with traditional landfilling and direct incineration, WtE not only reduces solid waste volume but also generates steam and electricity from waste combustion, providing renewable energy for industrial, residential, and urban infrastructure. However, WtE plants have complex processes, including waste collection, shredding, pre-treatment, combustion, boiler steam generation, and waste heat recovery, each of which places strict requirements on level switches, point level switches, and overall level measurement. Proper selection and layout of level and point level switches not only ensure safe operation of combustion furnace hoppers, boiler water levels, and ash handling, but also improve generation efficiency and enable intelligent, reliable, and efficient WtE operations.

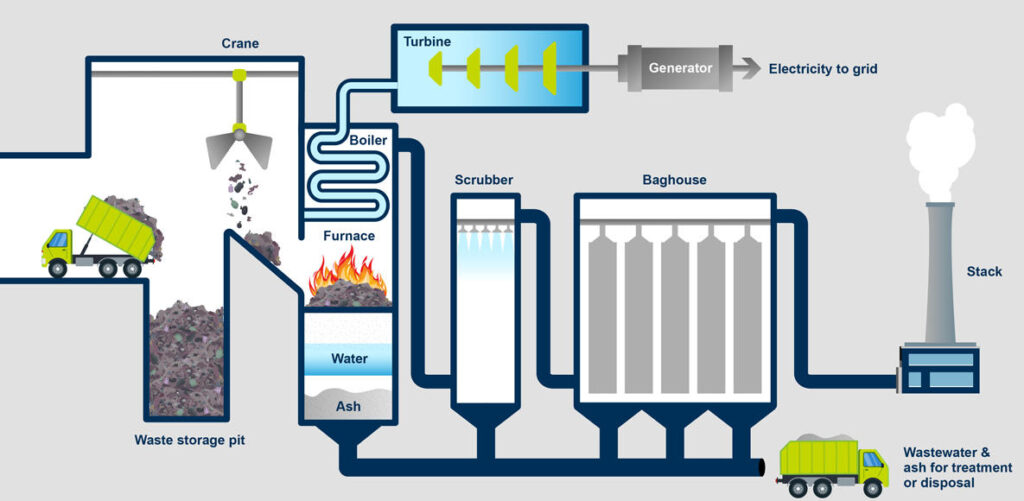

1. Overview of Waste-to-Energy Processes

WtE generally involves the following key stages:

Waste Collection and Storage

Urban waste is transported to waste pits or storage silos, consisting of a mixture of varying water content, corrosive components, dust, and foreign objects. In storage silos, waste continues to settle and ferment, producing liquid leachate.

Shredding and Homogenization

Waste is initially shredded and mixed using shredders or homogenizers to achieve uniform particle size, facilitating transportation and combustion. The shredded waste has variable moisture content and particle distribution, with liquids and solids forming slurry or semi-fluid mixtures.

Conveying and Storage

Homogenized waste is transported to pre-boiler hoppers or silos. Hoppers may be inclined, screw-conveyed, or bucket-elevator-equipped. Each hopper requires real-time level monitoring to prevent overfill or empty-run conditions.

Combustion and Energy Recovery

Waste is burned in the furnace to produce steam, which drives turbines to generate electricity. The combustion stage involves high temperatures, corrosive gases, and ash, requiring reliable liquid and solids level measurement in furnaces, ash hoppers, and steam systems.

Ash Handling and Flue Gas Treatment

Combusted ash enters ash silos, while flue gas is treated via desulfurization, dust removal, and heat recovery systems. Ash silos typically contain coarse, low-moisture but corrosive solids; point level switches must be wear- and corrosion-resistant.

From this process overview, it is clear that WtE involves liquids, slurries, wet solids, and dry solids, with each stage having different requirements for level and point level monitoring.

2. Common Level and Point Level Measurement Challenges in WtE

In practice, level and point level measurement in WtE plants faces multiple challenges that directly impact operational safety and efficiency.

1. Complex Media

WtE involves a wide variety of media, including leachate, slurry, dust, wet solids, and ash. These media often coexist, with low flowability and uneven particle sizes, which can destabilize level measurement. Traditional instruments must prioritize corrosion and wear resistance, while insufficient sensitivity may fail to detect level changes, causing false alarms or equipment misoperation.

2. Wide Temperature and Pressure Variations

Different WtE process stages have drastically different temperature and pressure conditions. For example, waste storage silos operate at ambient temperatures, while boiler ash hoppers may reach several hundred degrees Celsius, accompanied by pressure fluctuations from blowers or screw conveyors. High-temperature and high-pressure conditions challenge instrument durability and long-term reliability.

3. Dust and Contamination

WtE plants operate in environments with heavy dust, fly ash, and smoke, which can accumulate on sensors, affecting accuracy or causing instrument failure. Point level devices such as tuning fork level switches or vibrating rod switches can produce false or missed alarms if not properly installed or protected, posing risks to automation systems.

4. High Safety and Automation Requirements

Uncontrolled liquid or solids levels can lead to overflow, empty-run, combustion irregularities, or boiler incidents, threatening equipment and personnel safety. Level measurement systems must provide accurate monitoring, seamless integration with control systems, remote commissioning, real-time alarms, and parameter optimization to ensure production continuity and safety.

5. Multi-Stage Monitoring Complexity

WtE involves waste collection, shredding, pre-treatment, combustion, and ash handling, with each stage requiring different level or point level monitoring. Boiler water systems need continuous level measurement, furnace hoppers require point-level monitoring to prevent empty-run, and ash handling systems need real-time solids feedback. Different media, temperature, and pressure conditions demand careful instrument selection and layout.

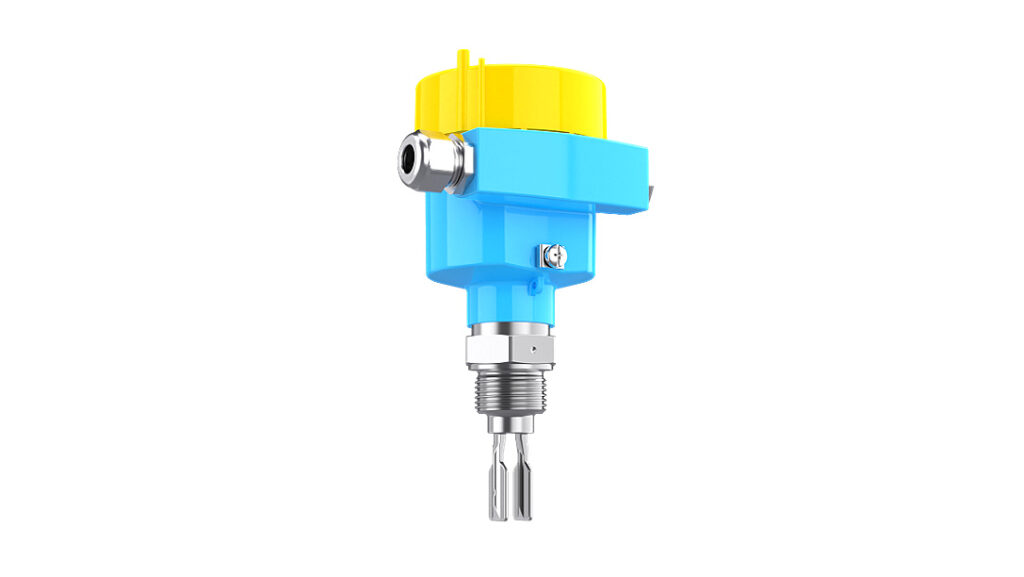

3. Point Level Switch Selection: Tuning Fork vs Vibrating Rod

Selecting the appropriate point level switch is crucial, depending on the media characteristics and measurement requirements at different WtE stages.

1. Jiwei Tuning Fork Level Switch (Vibrating Fork / Tuning Fork)

Principle and Features:

- Detects liquid level based on damping of fork vibration when contacted by liquid.

- Fast response, high sensitivity, suitable for liquids or low-viscosity slurry.

- Compact design, installable on top or side of tanks.

- Ideal for detecting preset liquid levels, preventing overflow or empty-run.

Application Stages:

- Leachate Storage Tanks: Rapid alarms prevent overfill or pump dry-run.

- Homogenized Slurry Hoppers: Top-level detection ensures continuous transfer.

Advantages:

- High sensitivity for liquids and low-viscosity slurry

- Flexible installation: top or side mounting

- Low maintenance, corrosion-resistant materials available

2. Jiwei Vibrating Rod Level Switch (Probe / Rod Level Switch)

Principle and Features:

- Dual-rod design generates vibration via motor; vibration damping by solids triggers alarm.

- Suitable for granular, powdery, wet solids, or settled materials.

- Supports high-temperature, high-pressure, and corrosive environments.

Application Stages:

- Pre-Boiler Conveying Hoppers: Detects full/empty levels of mixed granular waste, prevents overfill or dry-run.

- Ash Hoppers / Dry Solid Silos: Durable in high-temperature, dusty, and corrosive conditions.

Advantages:

- Works for dry solids, granular materials, and mixed waste

- Wear- and corrosion-resistant, suitable for high-temperature and dusty environments

- Stable performance, reliable switching

4. Typical Case Study: Longyan WtE Plant

Project Overview:

- Daily Capacity: 2,000 tons of waste

- Key Storage/Fluid Stages: Leachate tanks, homogenized hoppers, pre-boiler conveyors, ash silos

- Operating Conditions: Liquid temperature ambient, slurry ~50°C, ash ~150°C, high dust

Instrument Selection Table:

| Location | Media | Recommended Instrument | Reason |

|---|---|---|---|

| Leachate Tank | Liquid | Tuning Fork Level Switch | Clean liquid, high sensitivity, overflow/empty-run alarm |

| Homogenized Hopper | Slurry | Tuning Fork Level Switch | Surface level alarm, ensures continuous transfer |

| Pre-Boiler Conveyor | Wet Solids | Vibrating Rod Level Switch | Mixed granular waste, prevents full/empty, wear- and corrosion-resistant |

| Ash Silo | Dry Solids | Vibrating Rod Level Switch | High-temperature, dusty environment, reliable |

Results:

- Continuous level and point-level monitoring reduces manual inspections

- Prevents pump dry-run and hopper overfill, enhancing safety

- Ash silos operate stably at high temperatures, reducing maintenance frequency

- PLC/SCADA-compatible system enables remote alarms and data analysis

5. Summary and Selection Recommendations

- Liquids or Low-Viscosity Slurry: Prefer tuning fork level switches for fast, sensitive point-level detection; suitable for storage tanks, slurry hoppers, or boiler feedwater.

- Granular, Dry, or Mixed Solids: Prefer vibrating rod level switches for wear- and corrosion-resistant monitoring of ash silos, hoppers, and conveyors; ensures stable operation in harsh conditions.

- Key Selection Factors: Consider temperature, corrosion, dust concentration, media type, installation space, and ease of maintenance.

- Integrated Solution: WtE plants typically require both tuning fork and vibrating rod switches to monitor liquids and solids, achieving full-process safety and maintaining automation continuity.

Selecting the right point-level switches not only ensures safe operation but also optimizes processes, improves automation, reduces maintenance costs, and enables efficient and reliable energy recovery in WtE plants.

Waste-to-Energy, level measurement, radar level meter, tuning fork level switch, vibrating rod level switch, solid-liquid mixture, industrial automation, ash silo, leachate, level switch, probe level switch, industrial automation, WtE