Explosion-Proof Marking Explained: How to Read Ex Labels on Certified Equipment

How to Understand Explosion-Proof Markings on Certified Equipment

In hazardous environments such as refineries, petrochemical plants, gas stations, and fueling depots, all electrical and electronic equipment must be certified by authorized national agencies according to explosion protection standards, such as GB/T 3836-2021 (equivalent to IEC 60079 series). These certifications include an explosion-proof marking (Ex marking), which may look complex at first glance. This guide will walk you through how to interpret the letters and numbers on these markings.

What Is an Explosion-Proof Marking?

The explosion-proof marking provides key information about the equipment’s explosion protection method, applicable hazard zones, gas or dust groups, temperature class, and equipment protection level (EPL). Here’s a breakdown of its typical components:

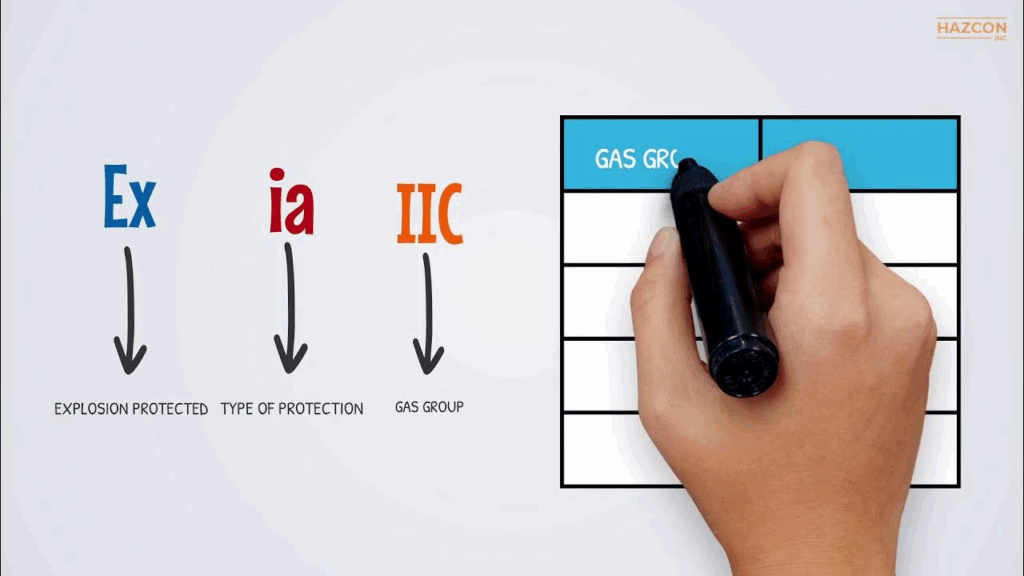

1. Ex Symbol

The “Ex” symbol indicates that the device is explosion-protected and has passed an official certification process for use in hazardous environments. This is an internationally recognized symbol.

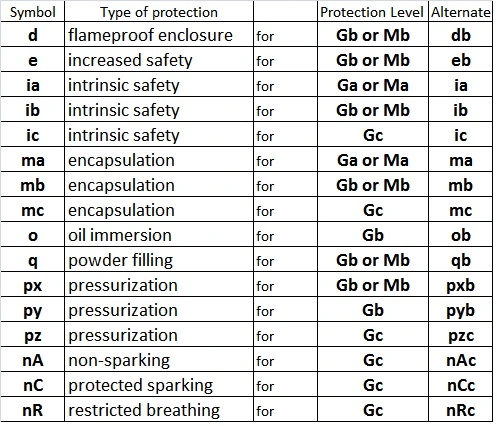

2. Protection Method

This refers to how the equipment prevents ignition in hazardous atmospheres. Common types include:

- i (Intrinsically Safe): Limits electrical energy to prevent sparking or heating that could cause ignition. It is further classified as ia, ib, or ic, with “ia” offering the highest level of protection, suitable even for Zone 0.

- d (Flameproof Enclosure): Contains an internal explosion and prevents its transmission to the surrounding environment. Flameproof equipment is classified as da, db, or dc, each offering different levels of protection.

- e (Increased Safety): Enhances safety by preventing excessive temperature and sparking through robust design.

- t (Dust Protection): Protects against ignition of explosive dust atmospheres using enclosures. Classified as ta, tb, or tc.

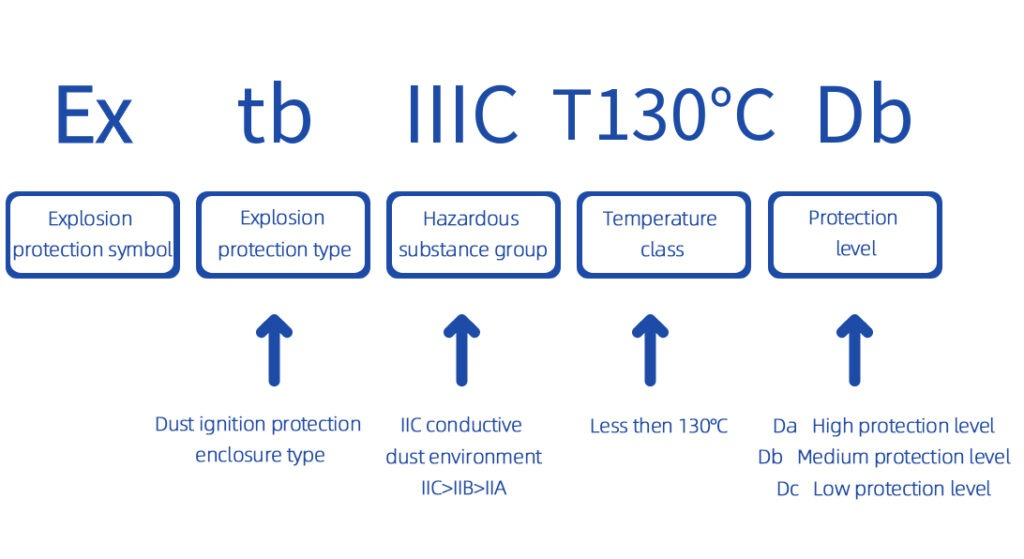

3. Equipment Group

This defines the type of explosive atmosphere for which the equipment is suitable:

- Group I: For underground coal mining (methane gas environments).

- Group II: For all other explosive gas atmospheres (surface industries). Further divided into:

- IIA – representative gas: propane

- IIB – representative gas: ethylene

- IIC – representative gas: hydrogen, acetylene (most dangerous)

Group IIC devices can be used in IIB and IIA conditions as well.

- Group III: For explosive dust environments (non-mining):

- IIIA – combustible flying fibers

- IIIB – non-conductive dust

- IIIC – conductive dust (most hazardous)

A device marked for IIIC can also be used in IIIA and IIIB environments.

4. Temperature Class

The temperature class indicates the maximum surface temperature the equipment can reach under worst-case but permitted operating conditions. For Group II (gas) environments, classes range from:

- T1 – ≤ 450°C

- T2 – ≤ 300°C

- T3 – ≤ 200°C

- T4 – ≤ 135°C

- T5 – ≤ 100°C

- T6 – ≤ 85°C

The selected temperature class must always be lower than the ignition temperature of the explosive gas or dust in the surrounding area.

5. Equipment Protection Level (EPL)

The EPL rating indicates the likelihood that equipment will become an ignition source in explosive atmospheres:

For Gas Atmospheres:

- Ga – Very high protection (safe even in Zone 0)

- Gb – High protection (suitable for Zone 1 & 2)

- Gc – Basic protection (Zone 2 only)

For Dust Atmospheres:

- Da – Very high protection (Zone 20)

- Db – High protection (Zone 21)

- Dc – Basic protection (Zone 22)

Protection level relationship: Ga > Gb > Gc (for gas), Da > Db > Dc (for dust)

Example: Interpreting an Explosion-Proof Marking

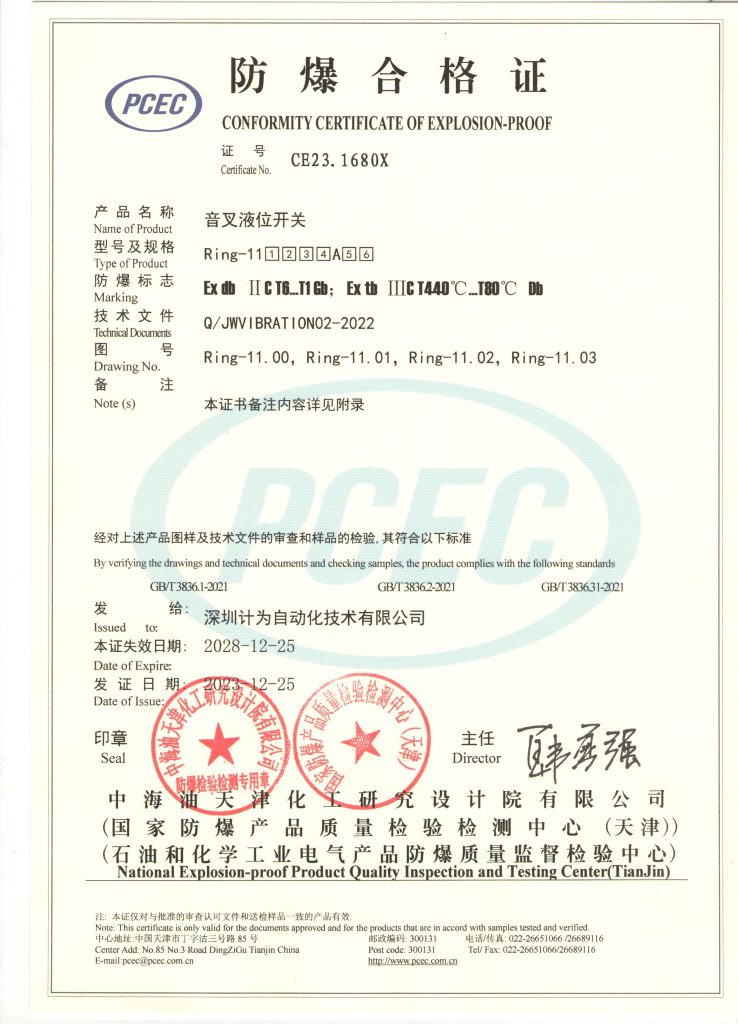

Let’s take the following marking from Jiwei Ring-11 tuning fork level switch as an example:

Ex db IIC T6…T1 Gb; Ex tb IIIC T440°C…T80°C Db

Here’s what it means:

- Ex – Certified explosion-proof equipment

- db – Flameproof enclosure (level db), suitable for EPL Gb (gas Zone 1 and 2)

- IIC – Applicable for the most hazardous gas group (hydrogen/acetylene), and thus also suitable for IIB and IIA

- T6…T1 – Equipment is suitable for environments requiring T1 to T6 classifications

- Gb – Equipment protection level for gas atmospheres, usable in Zones 1 and 2

- tb – Dust explosion protection using enclosure, level tb

- IIIC – Suitable for conductive dust, also covers IIIB and IIIA

- T440°C…T80°C – Device surface temperature ranges from 80°C to 440°C depending on application

- Db – Equipment protection level for dust environments, usable in Zone 21

Conclusion

Understanding explosion-proof markings is essential for ensuring the correct selection of equipment in hazardous environments. Each letter and symbol tells you critical information about the protection method, applicable atmosphere (gas or dust), zone classification, temperature safety, and more. Always check for valid explosion-proof certificates and markings before deploying any device in flammable or explosive environments.

For accurate application and compliance, consult standards like GB/T 3836 or IEC 60079, and ensure all equipment is tested by authorized certification bodies.