Differences Between Radar Level Meter and Ultrasonic Level Meter:Clear Advantages

Introduction

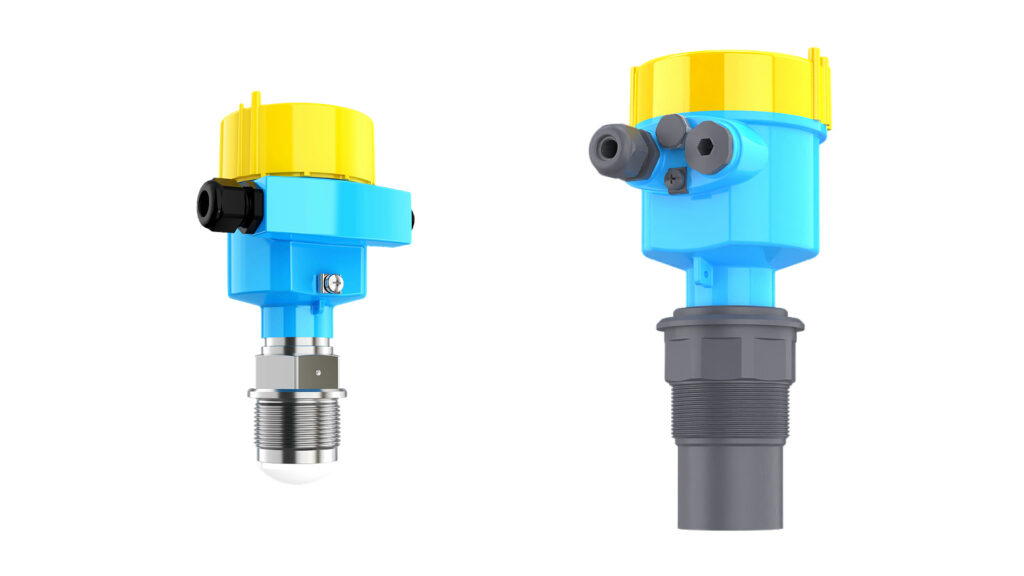

In the field of industrial automation, liquid level measurement plays a crucial role in process control, directly impacting production safety and operational efficiency. Among various level measurement technologies, radar and ultrasonic level meters stand out due to their non-contact measurement, safety, stability, and ease of maintenance. These advantages have made them widely adopted in petrochemical, power generation, environmental protection, water treatment, and food industries. However, many users face challenges in selecting between these two technologies: What are the fundamental differences in their working principles? Which operating conditions are each best suited for? And how do their performance characteristics compare?

This article provides a detailed analysis of radar level meters and ultrasonic level meters from multiple perspectives, including working principle, measurement performance, suitable applications, installation and maintenance, interference immunity, cost considerations, and real-world case studies, offering professional guidance for optimal instrument selection.

Key Differences Between Radar and Ultrasonic Level Meters

1. Working Principle

Radar Level Meters

Radar level meters operate based on the emission and reception of high-frequency electromagnetic waves. Typically utilizing microwave frequencies such as 26 GHz or 80 GHz, a radar antenna emits electromagnetic waves toward the liquid surface. These waves reflect back upon hitting the surface, and the device calculates the liquid level by measuring the time difference between emission and reception.

Radar technologies include:

- Frequency-Modulated Continuous Wave (FMCW) radar

- Pulse radar

- Guided wave radar (using probes or cables)

Among these, high-frequency FMCW radar provides superior accuracy and resolution.

Ultrasonic Level Meters

Ultrasonic level meters use high-frequency sound waves, usually between 20 kHz and 60 kHz, propagated through air. The transducer emits ultrasonic pulses which reflect off the liquid surface and return to the sensor. The device measures the time interval between emission and reception, then calculates the level based on the speed of sound in air.

Because sound waves travel through air, ultrasonic sensors are more susceptible to environmental factors such as temperature fluctuations, humidity, and dust, which can affect measurement accuracy.

2. Measurement Performance Comparison

| Performance Parameter | Radar Level Meter | Ultrasonic Level Meter |

|---|---|---|

| Maximum Range | Up to 120 meters | Generally up to 20 meters |

| Accuracy | ±1 mm or better | Typically ±5–10 mm |

| Signal Attenuation | Low, strong penetration | High, easily attenuated |

| Response Speed | Fast (especially FMCW) | Slower |

| Environmental Adaptability | Excellent in vapor, dust, and steam | Sensitive to condensation, dust, and wind |

| Installation Flexibility | Can be installed off-center, flexible angles | Requires vertical installation, strict angle constraints |

Overall, radar level meters outperform ultrasonic types in range, precision, and environmental robustness, particularly under challenging conditions such as high temperature, pressure, vapor, or dust.

3. Suitable Applications

Radar Level Meter

- High-temperature and high-pressure environments (e.g., >250°C, >40 bar)

- Closed vessels and stirred tanks

- Viscous or corrosive liquids

- Dusty, steamy, or foam-prone storage silos

- Applications requiring long-range and high-precision level measurement

Ultrasonic Level Meter

- Open reservoirs, sewage and regulation ponds under normal temperature and pressure

- Groundwater wells and stormwater drains

- Simple, non-critical applications requiring non-contact measurement

- Cost-sensitive projects with moderate accuracy requirements

4. Interference Resistance and Stability

Radar level meters, relying on electromagnetic waves, exhibit stronger immunity to interference. The 80 GHz radar variants feature narrow beam angles and high signal-to-noise ratios, effectively minimizing signal disruption from obstacles or mixers inside tanks.

Conversely, ultrasonic sensors are prone to performance degradation due to:

- Temperature variations affecting sound speed

- Condensation causing probe blockage

- Dust and spray causing ultrasonic scattering

Hence, radar meters demonstrate higher reliability and stability in harsh environments.

5. Cost and Total Ownership Considerations

Ultrasonic level meters are generally more affordable upfront, making them attractive for entry-level, non-critical applications.

Radar level meters come at a higher initial investment; however, advancements in technology and domestic manufacturing have reduced costs significantly. When factoring in maintenance and operational reliability, radar meters often provide superior cost-effectiveness over the long term due to lower downtime and fewer failures.

6. Installation and Maintenance

| Aspect | Radar Level Meter | Ultrasonic Level Meter |

|---|---|---|

| Installation | Flexible placement; off-center or near walls allowed | Requires direct vertical positioning; angle sensitive |

| Probe Condensation | Minimal effect on high-frequency radar | Condensation can cause measurement errors |

| Configuration | Supports HART, Bluetooth, and remote tuning | Usually manual or basic adjustments |

| Maintenance | Low frequency; near maintenance-free | Requires occasional cleaning and recalibration |

Radar level meters integrate well with smart factories and digital control systems, enabling remote parameter adjustment, trend analysis, and diagnostics. Ultrasonic meters tend to be simpler but require more hands-on upkeep.

7. Real-World Case Studies

Case 1: Radar Level Meter in Acid Pickling Tanks

A steel mill’s acid pickling line uses 98% sulfuric acid, which is highly corrosive and volatile, causing traditional ultrasonic sensors to fail due to condensation and corrosion. Switching to an 80 GHz horn antenna radar meter provided stable measurements with zero downtime over three years.

Case 2: Ultrasonic Level Meter in Wastewater Treatment

A municipal wastewater plant employs ultrasonic sensors in open regulation ponds where the level changes slowly, accuracy demands are moderate, and budget constraints are tight. The ultrasonic meters have operated reliably for over five years, demonstrating their suitability for cost-sensitive, straightforward applications.

8. Summary and Selection Recommendations

| Factor | Recommended Sensor Type | Notes |

|---|---|---|

| High temperature/pressure | Radar level meter | Electromagnetic waves unaffected |

| Dusty or steamy environments | Radar level meter | Resistant to dust interference |

| Budget constraints | Ultrasonic level meter | Lower upfront cost |

| Smart factory integration | Radar level meter | Supports advanced protocols and remote configuration |

| Simple open reservoirs | Either | Both suitable for water tanks and wells |

Choosing between radar and ultrasonic level meters should be based on actual process conditions, accuracy requirements, budget, and maintenance considerations to ensure the best balance of cost and performance.

9. Advantages of Jiwei Radar Level Meters and Brand Strength

As radar level meter technology advances, domestic manufacturers with strong R&D and quality assurance have emerged. Jiwei Instruments stands out as a leading brand in this sector, offering reliable radar level measurement solutions favored in various industrial applications.

Jiwei JWrada Series Highlights:

- Utilizes cutting-edge 80 GHz FMCW radar with narrow beamwidth and high signal-to-noise ratio, ideal for complex conditions involving vapor, obstacles, or dust

- Robust anti-interference features, including zero blind zone and adaptive signal processing, to handle stirring, buildup, and foam interference

- Flexible installation and smart configuration, with Bluetooth-enabled wireless setup via Jiwei’s proprietary “Jiwei Smart Control” app for remote parameter setting, level trend visualization, and fault diagnosis

- Multiple certifications including Ex explosion-proof, suitable for stringent chemical, metallurgy, and pharmaceutical environments

Jiwei Brand Profile:

With over a decade dedicated to process measurement, Jiwei combines in-house R&D with vertically integrated manufacturing to ensure consistent product quality and rapid technological updates. Jiwei serves a global client base, partnering with high-end equipment manufacturers and automation system integrators across Southeast Asia, Europe, and beyond. The company prioritizes long-term reliability and customer value, positioning itself as one of China’s top three radar level meter brands.

Conclusion

With industrial automation rapidly evolving, liquid level measurement instruments are increasingly advancing toward smarter, more stable, and higher-precision technologies. Radar level meters represent the forefront of this progress, while ultrasonic meters remain indispensable for many fundamental applications. Understanding their differences is key to selecting the right solution and optimizing system performance and upgrades.

For further information on Jiwei high-frequency radar level meters or personalized selection guidance, please visit our technical resource center or contact our expert team for tailored support.