What is Dielectric Constant?

Dielectric Constant: The Hidden Key Underpinning Automation Hardware

As industrial automation evolves from traditional electrical control toward data-driven, closed-loop systems, “digitalization” and “intelligence” have become the mainstream narratives. Yet, hardware remains fundamentally physical—many enduring issues actually stem from neglected physical parameters.

One such parameter is the dielectric constant (or relative permittivity), a critical yet often overlooked variable. It doesn’t dictate algorithm speed or control logic, but it intimately impacts every hardware layer—from sensors and capacitive filters to cables, PCB signal integrity, insulation reliability, and measurement accuracy.

Let’s peek through an engineer’s lens to understand why dielectric constant deserves system-level consideration.

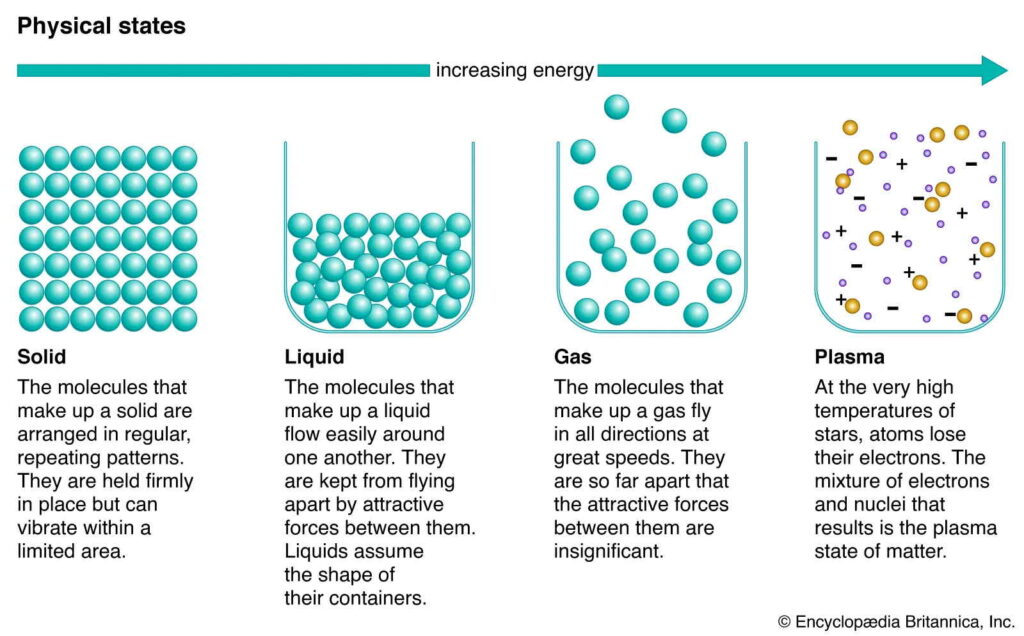

1. What Is the Dielectric Constant and Why Is It Important?

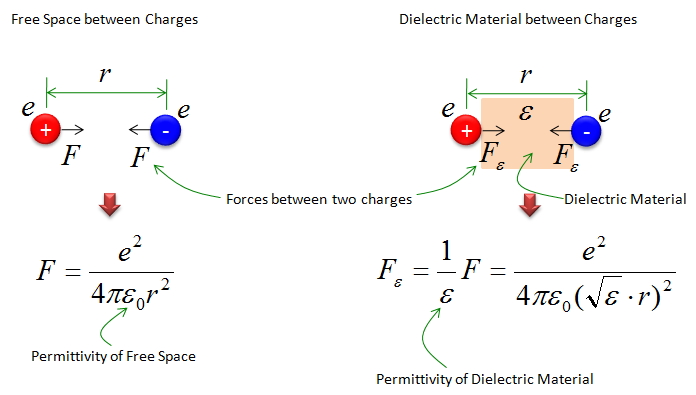

The dielectric constant describes a material’s ability to polarize under an electric field, determining how much electric energy it can store and how the field attenuates. It critically affects:

- Capacitance behavior: Influences capacitor, coupling, and filter performance

- Electric field distribution: Affects high‑frequency signal propagation and signal integrity

- Electromagnetic coupling: Impacts sensor sensitivity, cable crosstalk, interference paths

- Material response: Governs dielectric-based detection (e.g., humidity, level sensing)

In automation, the dielectric constant isn’t niche—it’s the governing variable in many physical domains.

2. The “Invisible Variable” in Automation Hardware

Filter & Capacitor Performance

Capacitor value scales with dielectric constant, but εr varies dramatically across temperature and frequency in materials like X7R or polypropylene. For instance, X7R capacitance can drop over 20% at high temperature—a risk often overlooked in filter design.

Signal Integrity in Communication

High-speed buses (EtherCAT, Profinet, SerDes, etc.) rely on PCB dielectric consistency. Material choices like FR‑4 or Rogers must consider εr stability; mismatches cause reflections, delay skew, and bit errors.

Insulation in High‑Voltage Systems

In systems like medium voltage drives or traction control, dielectric constant influences field uniformity. Poor εr design can concentrate fields, cause partial discharge, and prematurely fail insulation layers.

3. Five Critical Impact Areas in Automation

- Filter & Cap Capacitors

High-εr materials risk drift and performance degradation in power modules and noise filters. - Communication Signal Integrity

Dielectric mismatches cause propagation issues—especially critical at >100 MHz signal frequencies. - Insulation & HV Isolation

εr impacts field distribution and breakdown risk, requiring careful material selection for fairness and longevity. - Level & Fluid Measurement

Radar level sensors depend on εr contrast between media—presence of foam or emulsions complicates detection, so modeling dielectric mixing is essential. - Material & Moisture Sensing

Humidity sensors exploit εr shifts in porous media. Precise models must compensate for temperature and pressure dependencies.

4. Engineers Must Dive Deeper into the Physical Layer

Many system failures spring from engineers treating hardware like Lego—knowing part numbers but not field responses. In high‑frequency, high-precision automation, this superficiality is costly.

The future demands collaboration between physics and algorithms:

- Custom dielectric materials: Enabling miniaturization and thermal stability via composites

- “Physical AI” modeling: Building multi-variable models (εr, T, humidity) for smarter sensing

- Physics‑aware design: Reading dielectric spectra and field distribution, not just specs

In essence, dielectric constant is the deepest bedrock of industrial intelligence.

Conclusion: Solid Hardware Makes Digital Truly Reliable

Dielectric constant isn’t a flashy buzzword—but the more overlooked it is, the more it determines system limits and stability.

As automation leans heavily on complex control and networked equipment, revisiting and engineering this fundamental physical parameter is a competitive edge. Dielectric constant may be just one variable—but starting here ensures a physically robust foundation for digital systems.