How Radar Level Meters Prevent Liquid Level Control Chain Reactions

In modern industrial systems, liquid level control is far more than a simple point measurement—it is a complex, interconnected “system battle.” Once liquid level control fails, it not only disrupts the immediate process but also triggers cascading failures across systems and workshops, potentially leading to full production line shutdowns, equipment damage, and frequent safety incidents.

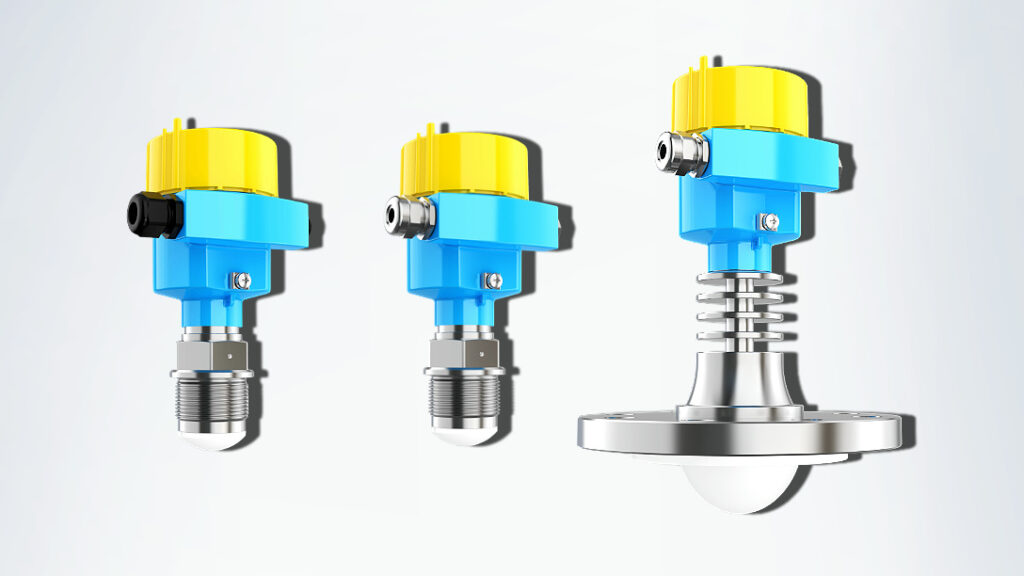

Within this intricate system, radar level meters play the crucial role of a “gatekeeper,” leveraging non-contact measurement, high reliability, and strong interference immunity to precisely detect every drop of liquid and establish the first line of defense for system safety.

Chain Reactions Caused by Liquid Level Failures: Real Cases and Technical Insights

Case 1: Emergency Shutdown Triggered by Excessive Liquid Level in Coating Plant Reactor

A major chemical coating plant experienced a reactor overflow due to a liquid level sensor drifting from lack of calibration. The PLC incorrectly judged the tank as not full, leading to continued filling and overflow. The leaked liquid infiltrated the heating jacket, causing a temperature control system short circuit, which triggered an emergency shutdown of the entire workshop and disrupted downstream packaging operations.

Technical Analysis:

- Measurement Accuracy is Critical: Reactors often contain foam and mechanical agitation, which easily interfere with traditional ultrasonic or float level sensors, causing measurement drift.

- Radar Level Meter Advantages: The 80GHz FMCW (Frequency Modulated Continuous Wave) radar offers a narrower beam angle and higher dynamic range, effectively distinguishing foam from true liquid surfaces and providing stable, accurate level readings.

- Prevention Recommendations: Use high-frequency radar equipped with dynamic foam filtering and near-field echo recognition algorithms, such as the Jiwei JWrada® series, supporting steam compensation and nonlinear vessel correction for stable measurement in extreme conditions.

Case 2: CIP System Cleaning Fluid Depletion Causes Hygiene Monitoring Failure

In a food processing plant, a CIP (Clean-In-Place) cleaning tank’s liquid level sensor error caused premature emptying. The cleaning cycle was incomplete but undetected by the system, resulting in microbial contamination found by third-party inspectors. This led to compliance penalties and massive product recalls.

Technical Challenges:

- Food industry tanks are typically small, stainless steel, and sealed, prone to condensation and liquid surface fluctuations.

- Sensors must have food-grade certifications (e.g., FDA, 3-A) and ensure dead-zone-free detection.

Radar Level Meter Solutions:

- Small-diameter lens antenna design to fit narrow CIP tank nozzles.

- Anti-condensation algorithms combined with built-in heaters to prevent mirror condensation that causes measurement errors.

- Hygienic process connections (e.g., clamp fittings) and corrosion-resistant PTFE probe materials ensure cleanliness and durability.

In-Depth Technical Analysis: How Radar Level Meters Ensure “Chain Stability” in Liquid Level Control

- From Point to System: Level Sensors as Automation Triggers

Radar level meters not only provide real-time level data but serve as critical inputs to PLC/DCS control logic, dictating valve operation, pump start/stop, and alarm activation.

If level signals drift or become distorted, the entire automation chain receives faulty inputs, risking incorrect operations and cascading failures.

- Dynamic Process Modeling: Key Technical Indicators

| Technical Parameter | Description | Impact on System Performance |

|---|---|---|

| Operating Frequency (GHz) | Higher frequency = narrower beam & better resolution | 80GHz adapts better to tight spaces & complex conditions, reducing multipath interference |

| Antenna Type | Parabolic, lens, rod shapes determine echo quality | Lens antennas preferred for low dielectric containers; rod antennas for metal tanks |

| Echo Dynamic Range | Wider range improves filtering of false echoes and noise | Essential for stable signals amid agitation and steam |

| Signal Processing Algorithms | Include target identification, clutter suppression, foam filtering | Directly affect measurement accuracy and interference resistance |

Five Key Strategies to Prevent Liquid Level Failures and System Collapse

- Redundancy with Limit Switches: Combine radar level meters with tuning fork or vibrating rod limit switches in high-risk tanks to avoid single-point failures.

- Real-Time Radar Health Monitoring: Choose instruments with echo quality diagnostics, temperature drift compensation, and self-fault detection to ensure continuous measurement.

- Regular Calibration with Cloud-Based Remote Diagnostics: Use Bluetooth-enabled mobile apps and cloud platforms (e.g., Jiwei JWrada®) for on-site and remote joint calibration, reducing maintenance costs and improving accuracy.

- Incorporate Level Change Rate Logic in DCS: Monitor liquid level velocity to detect abnormal jumps or sensor freeze, preventing false alarms or undetected failures.

- Pre-Project Interference Simulation: Simulate foam, dust, and steam interference during design to validate echo stability and optimize sensor selection.

Conclusion: The Indispensable “Gatekeeper” of Liquid Level Control

Radar level meters are more than sensors—they are the safety barrier and control hub of automation systems. They determine the “go/no-go” decision in liquid level control chains, ensuring continuous material flow and production safety. Losing this critical link causes rapid cascading failures that can cripple entire factories like dominoes. Selecting high-performance radar level meters combined with comprehensive warning systems is essential for robust modern industrial automation.