Analysis of Field-Level Controller in Automation Projects

In many automation projects, a common phenomenon can be observed: the control logic of the field-level controller (PLC) runs stably, the PLC scans reliably, and equipment actions are executed as expected, yet the operation environment and site management remain chaotic. When abnormal events occur, operators often habitually choose to “restart first.” Although data is being collected, no one can accurately determine where the problem started to degrade. When alarm systems trigger frequently, operators tend to repeatedly acknowledge them without further analysis. Management, when questioning the causes of downtime or production anomalies, often has to rely on experience or guesswork. This indicates that the root cause is not the correctness of the field-level control logic itself, but rather the lack of observability, traceability, and manageability across the control system. While the field-level controller ensures “correct control,” the system-level state information is often unclear, leading to chaotic site management.

Role of Field-Level Controllers in Automation Systems

The core responsibility of a field-level controller in automation systems is to ensure that equipment operates reliably according to the designed control logic. PLCs or other controllers are responsible for deterministic execution of closed-loop control, interlocks, and action timing. This constitutes the engineering value of the field-level controller. In practice, the design of the controller must consider various uncertainties in the field, including sensor signal fluctuations, actuator response delays, network interference, and state consistency after device power cycles or PLC restarts. Experience shows that although the controller can ensure correct execution of control actions, if state acquisition, signal processing, and anomaly detection do not account for noise or fluctuations, the system may still appear chaotic from a management perspective.

For example, in production lines with multiple devices operating concurrently, if the field-level controller does not implement proper state filtering and edge detection, momentary signal changes may trigger repeated control actions or misinterpret faults. Although the PLC may appear to function normally, operators and shift supervisors are unable to accurately identify problem points based on system data, ultimately resulting in a scenario of “equipment running, but site chaotic.” Therefore, the field-level controller must not only guarantee correct control actions but also provide reliable state acquisition and signal processing to deliver interpretable operational information to higher-level systems and management.

Field-Level Controller and Data Quality Management

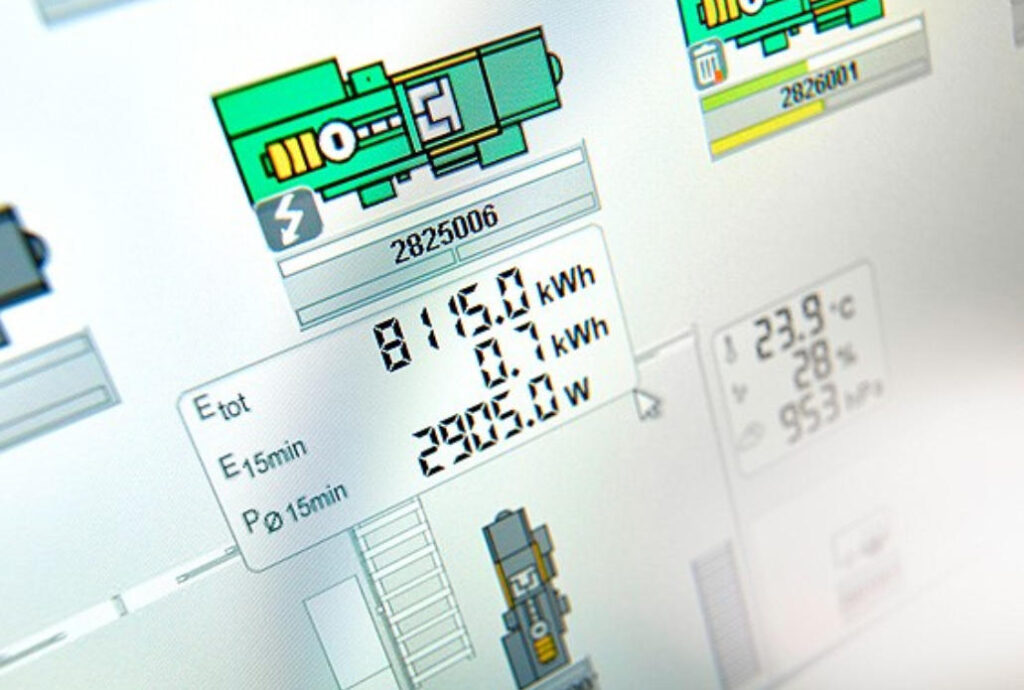

In automation engineering, data acquisition by the field-level controller must address not only output reliability but also the stability and credibility of input signals. In real industrial environments, sensor signals may be affected by noise, cable aging, or communication packet loss, and PLCs often receive momentary fluctuations or abnormal signal variations. Without appropriate filtering, delayed triggers, or anti-jitter logic in the PLC program, these transient changes may be misinterpreted as equipment faults or abnormal states, leading to alarm flooding, operator misoperation, and increased site complexity. In practice, an effective field-level controller design ensures timely control response while applying stable-state judgment, delayed triggers, and anomaly buffering, thereby providing stable and interpretable signals for operators and higher-level systems.

Furthermore, field-level controllers are responsible for certain historical record-keeping. At critical process points, PLCs must record state changes, alarm triggers, and operator inputs to form a basic traceable data chain. Although these records may not be directly displayed to operators, they are crucial for fault analysis, process optimization, and downtime attribution. Without such records, even if data is collected, it cannot support site management or accountability, and production efficiency and safety management remain limited.

Impact of Field-Level Controller Design on System Performance

The design of a field-level controller not only affects the reliability of individual equipment actions but also directly determines the stability and controllability of the overall production system. In complex process environments, such as multi-stage reactors or continuous conveyance production lines, each PLC’s control logic must consider interaction and state consistency with other devices. Field-level controllers handling abnormal or boundary conditions must define clear action priorities and state transition rules to prevent unpredictable system behavior. Controller programs must align with operational procedures and safety standards, ensuring that operators can interpret system states accurately and respond correctly to anomalies, rather than creating additional confusion.

In large-scale projects, the reliability of the field-level controller directly affects the credibility of production data and the operational manageability of equipment. Even if control logic is correct, failure to handle signal noise, provide interpretable state information, or record critical events prevents management and operators from relying on system data for decision-making. This highlights that field-level controllers are not only central to control execution but also foundational for production management, state visualization, and anomaly analysis.

Conclusion

The core value of field-level controllers in automation systems lies in ensuring control actions are correct, stable, and traceable. In engineering practice, they are not only executors of control actions but also the foundation for reliable field data and actionable management. A well-designed field-level controller can process signal noise, provide interpretable state information, and record critical events and anomalies, forming a stable data foundation that supports production management and process optimization. As projects grow more complex, the design of field-level controllers increasingly determines system stability, operational controllability, and whether site management can be efficient, data can be trusted, and anomalies can be fully traced.