Relationship of Radar Level Meter Range with Steam, Dust, and Bubbles: An In-Depth Analysis

Abstract

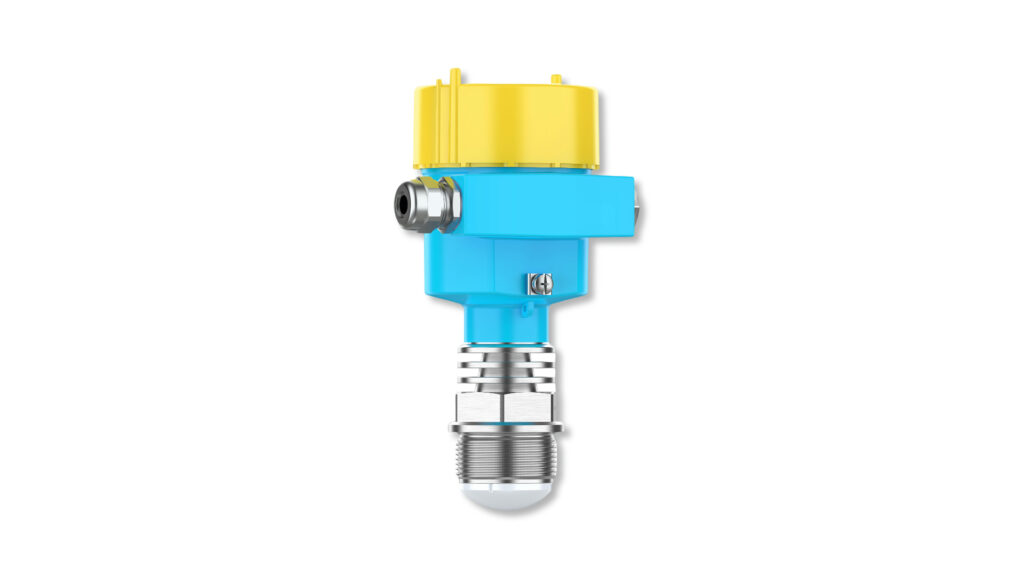

Radar level meters are widely used in industrial process control due to their non-contact measurement and high reliability. However, their effective measuring range is limited by the dielectric properties of the measured medium and on-site environmental conditions. Particularly in the presence of complex interferences such as steam, dust, and bubbles, measurement stability and maximum effective range can be significantly reduced. This article systematically analyzes the impact mechanisms of these three factors on radar level meter range, focusing on the 80GHz radar frequency band. It also proposes optimization strategies based on the latest technological developments, providing theoretical and practical references for radar level measurement system selection and application.

1. Introduction

Radar level meters determine liquid or solid levels by emitting electromagnetic waves and measuring the time delay of the reflected signals from the material surface (Krupka et al., 2020). With the advancement of radar technology—from early 6GHz and 26GHz systems to today’s mainstream 80GHz frequency—the directional accuracy, resolution, and interference immunity of level meters have significantly improved (Ludwig, 2022). However, in environments laden with steam, airborne dust, or media containing bubbles, electromagnetic wave propagation suffers from multiple interferences, which directly affect the meter’s range and measurement accuracy. A clear understanding of these physical interference mechanisms is critical to ensuring safe and efficient industrial process control.

2. Impact of Steam Environment on Radar Measuring Range

Steam influences radar wave propagation primarily through electromagnetic wave absorption and scattering. High-temperature water vapor molecules possess polar characteristics that strongly absorb electromagnetic waves, causing energy attenuation especially in the microwave band (Zhang et al., 2021). At steam temperatures above 100°C and near-saturation humidity, the absorption effect on high-frequency radar waves (such as 80GHz) is significantly greater than at lower frequencies, potentially reducing echo signal amplitude below detection thresholds and shortening measuring range or interrupting measurements.

Moreover, condensation is a critical issue in steam environments. When the radar antenna temperature falls below the steam dew point, condensed water forms on the antenna radome (e.g., PTFE), leading to false echoes or signal scattering (Rohal’-Ilkiv et al., 2023). This phenomenon alters antenna directivity and can obscure true echoes, further impacting the effective measuring range.

Engineering Countermeasures:

- Utilize radar level meters equipped with antenna heating to prevent condensation.

- Deploy intelligent echo processing algorithms with steam suppression features.

- Optimize installation locations to minimize steam accumulation around antennas.

3. Impact of Dust Environment on Radar Measuring Range

Dust affects radar signals mainly through multipath scattering, signal attenuation, and foreground interference. In industries such as mineral processing, cement, and coal, dust particle sizes vary from several micrometers to hundreds of micrometers, with particle size distribution and concentration directly determining scattering intensity. According to Mie scattering theory, scattering is strongest when dust particle diameters approach the radar wavelength. For 80GHz radar, with a wavelength around 3.75mm, coarse particles cause more pronounced signal interference (Wei et al., 2022).

High dust concentration layers create “virtual reflection surfaces” within the signal path, resulting in false level detections or loss of echo signals. Under extreme conditions such as dust storms during material loading, radar signals can be completely absorbed or scattered, rendering level measurement impossible.

Engineering Countermeasures:

- Select intelligent radar meters with advanced algorithmic filtering to improve signal recognition accuracy.

- Employ guided-wave radar or install dust shields to mitigate dust interference.

- Design measurement angles to avoid direct dust flow paths.

4. Impact of Bubbles on Radar Measuring Range

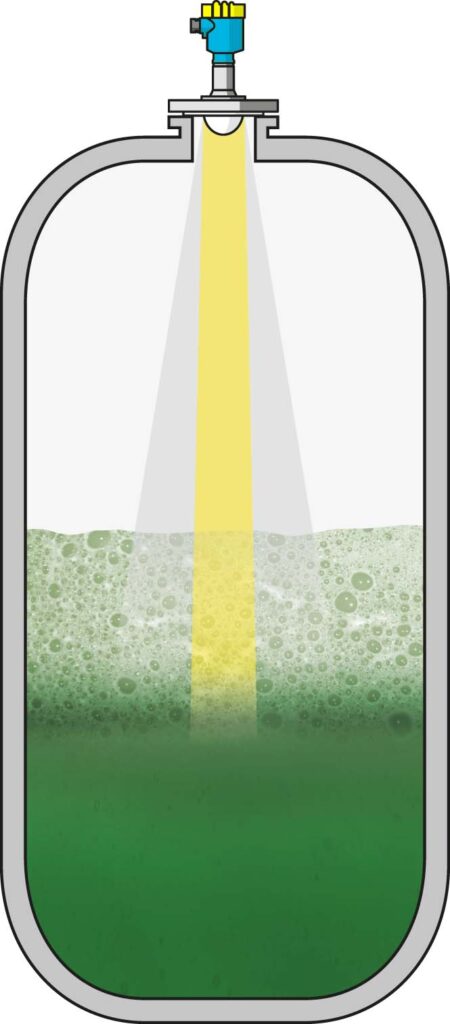

In liquid media such as fermentation tanks, wastewater pools, and condensate towers, bubbles are commonly present. Bubbles have a dielectric constant much lower than the liquid, and their interfaces cause strong reflections, leading to premature echo returns above the actual liquid surface, forming false level indications. Additionally, bubbles cause random scattering of radar waves, reducing echo energy and degrading measurement range.

Though high-frequency radar waves exhibit strong directionality and high resolution, their reflected energy on low dielectric foam surfaces is weak, especially at low foam densities, resulting in ineffective echo acquisition (Klauser et al., 2020). Increased surface agitation in tanks with agitators can also cause echo instability.

Engineering Countermeasures:

- Employ radar systems with dynamic echo recognition algorithms that differentiate bubbles from true liquid surfaces.

- Set echo thresholds and interference shielding windows to filter out atypical echoes.

- Use high transmission power radar to enhance penetration through bubble layers.

5. Range Control Under Combined Interference Factors

In practical applications, these three types of interference often coexist, such as in hot dust environments (steam plus particulates) or fermentation tanks with both bubbles and dust. Therefore, radar range design requires comprehensive optimization:

- Frequency Selection: Higher frequencies (e.g., 80GHz) provide narrower beam angles and superior near-range resolution, suitable for confined spaces or interference-rich environments (Hoffmann & Müller, 2022).

- Antenna Materials and Packaging: Recommend PTFE radomes to prevent condensation and ensure corrosion resistance.

- Algorithm Optimization: Integrate AI-based dynamic waveform analysis for real-time interference source identification and effective echo extraction.

- Measuring Distance Verification: During product selection, perform range reduction evaluation considering steam humidity, dust concentration, and foam thickness, leaving reasonable safety margins.

6. Conclusion

Radar level meters in environments with steam, dust, and bubbles experience complex physical interference mechanisms that impact effective measuring range. Through proper product selection, installation optimization, and the application of advanced signal processing algorithms, measurement stability and reliability can be significantly enhanced in challenging industrial conditions. Future smart radar systems combining multi-sensor fusion and AI algorithms will demonstrate even stronger adaptability to extreme environments.

References

Hoffmann, M., & Müller, T. (2022). Advances in 80 GHz radar technology for industrial level measurement. Journal of Sensors and Measurement Engineering, 45(3), 211–219. https://doi.org/10.1016/jsme.2022.03.008

Klauser, R., Benz, H., & Fuchs, T. (2020). Radar measurement in foam and gas-liquid interfaces: Challenges and solutions. Process Automation Journal, 58(4), 34–42.

Krupka, J., Klinger, J., & Luthra, P. (2020). Electromagnetic wave propagation in wet vapor environments. IEEE Transactions on Microwave Theory and Techniques, 68(2), 623–634. https://doi.org/10.1109/TMTT.2019.2958890

Ludwig, A. (2022). Narrow beam radar and signal processing for harsh industrial applications. Industrial Instrumentation Review, 29(1), 17–23.

Rohal’-Ilkiv, B., Bobalo, Y., & Horodetska, N. (2023). Condensation effects on radar antenna performance in steam-rich environments. Journal of Industrial Measurement Technology, 37(1), 89–97.

Wei, G., Chen, L., & Zhang, Y. (2022). Impact of particulate scattering on millimeter-wave radar in dusty environments. Sensors and Actuators A: Physical, 336, 113433. https://doi.org/10.1016/j.sna.2022.113433

Zhang, L., Huang, F., & Xu, Q. (2021). Influence of steam saturation on high-frequency radar level measurement. Chinese Journal of Process Instrumentation, 42(6), 88–93.