What Do High and Low Mean on Level Instruments?

In the field of liquid and solid level measurement, almost every level instrument—whether it is a vibrating rod level switch, tuning fork level switch, or differential pressure level transmitter—features markings for High and Low. Despite their ubiquity, many engineers, particularly those new to the field, often struggle to fully understand their meaning. Are these labels referring to installation positions, alarm points, or signal directions? This article provides an in-depth technical explanation.

High and Low: Definition and Core Concept

In level instrument, High and Low are relative concepts that represent preset points of liquid or material levels within a vessel or silo. They do not merely indicate physical height, but rather correspond to specific control or alarm setpoints.

- High: Refers to the high-level point at which the instrument triggers a signal when the liquid or material reaches or exceeds this level. This signal typically warns that the tank or silo is approaching full capacity and that appropriate actions, such as stopping the feed or triggering a high-level alarm, should be taken.

- Low: Refers to the low-level point at which the instrument sends a signal when the liquid or material drops to or below this level. This serves as a prompt to refill or take necessary process actions to avoid empty tanks or insufficient material levels.

In short, High and Low are tightly associated with alarm points and control points, rather than simply denoting physical height.

Applications Across Different Level Instruments

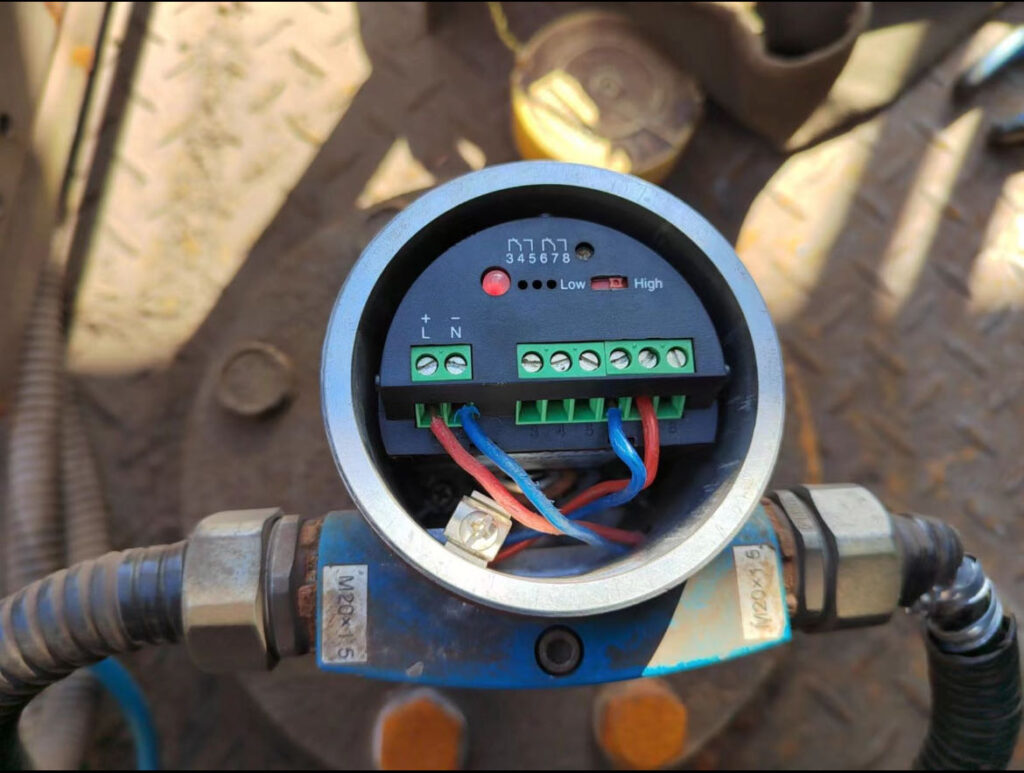

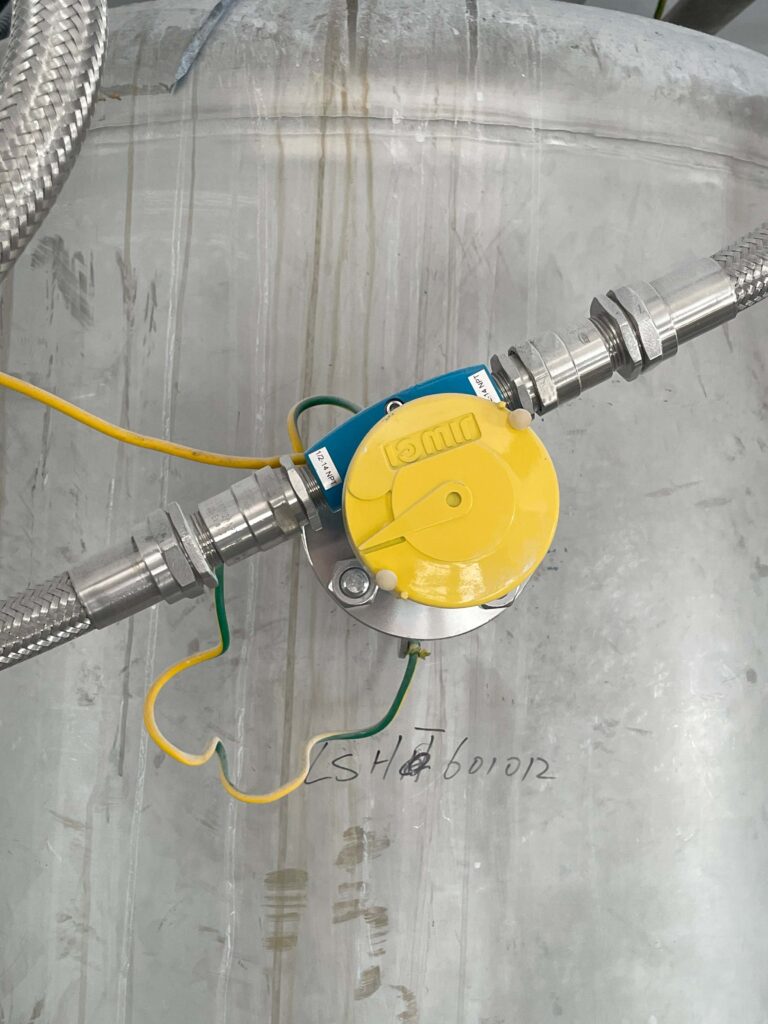

1. Level and Point-Level Switches

Devices such as tuning fork level switches, vibrating rod level switches, and RF admittance switches typically do not have fixed High or Low points at the factory. Instead, users select the installation positions according to process requirements:

- Top installation: Functions as a High-Level Switch, preventing overfilling or overflow.

- Bottom installation: Functions as a Low-Level Switch, preventing empty tank conditions or equipment dry running.

2. Continuous Level Instrument

For continuous level instruments like radar level meters or differential pressure transmitters, High and Low often correspond to the span endpoints of the measurement range:

- Low (LRV, Lower Range Value): The lower limit of the measurement range, typically corresponding to the tank bottom or a pre-defined zero point.

- High (URV, Upper Range Value): The upper limit of the measurement range, usually corresponding to the maximum design level or tank top.

Signal output is commonly mapped accordingly; for example, in a 4–20 mA current loop, 4 mA corresponds to Low and 20 mA corresponds to High.

3. Alarm and Interlock Systems

Within DCS or PLC systems, High and Low points are often further subdivided into multiple alarm levels:

- HH (High High): Extreme high level, triggers emergency interlocks or shutdowns.

- H (High): High-level alarm, indicating the tank is approaching the upper limit.

- L (Low): Low-level alarm, warning that material or liquid is approaching the lower limit.

- LL (Low Low): Extreme low level, triggers emergency actions such as pump protection.

These classifications ensure that control systems can respond appropriately to various process conditions.

Common Misunderstandings in Practice

- Confusing High/Low with installation position

Some engineers assume the High/Low markings on the instrument refer to the physical installation orientation. In reality, they generally denote the signal or measurement range endpoints. - Overlooking alarm and control logic

If High/Low points are set without considering DCS/PLC logic, alarms may trigger in reverse, or interlocks may fail, causing safety or process issues. - Mixing process safety and process control concepts

High/Low in a Safety Instrumented System (SIS) indicates interlock levels, whereas in a Process Control System (PCS), it often refers to standard alarms. Confusing these roles can compromise both safety and operational efficiency.

Conclusion

High and Low points on level instruments are far more than simple indicators of “high” or “low” physical positions. They represent critical process setpoints, measurement range endpoints, and alarm logic integration. Proper understanding requires consideration of:

- The measurement type (point-level switch or continuous measurement),

- Control requirements (alarm vs interlock),

- Integration into higher-level systems (DCS/PLC configuration).

By correctly interpreting High and Low, engineers can avoid operational errors, enhance safety, and optimize measurement and control strategies, ensuring stable and secure process operation. level instrument