Why Radar Level Meters Are Replacing Ultrasonic Level Meters

Abstract

Radar level meters—particularly 80GHz FMCW radar—are becoming the dominant choice in industrial level measurement. While ultrasonic level meters were once widely used due to their affordability, radar is steadily replacing them in industries such as chemical, food, water treatment, and bulk solids. This shift is driven by radar’s robustness, accuracy, smaller dead zones, and compatibility with Industry 4.0 digital systems. This article explores why radar technology is overtaking ultrasonic, supported by academic references.

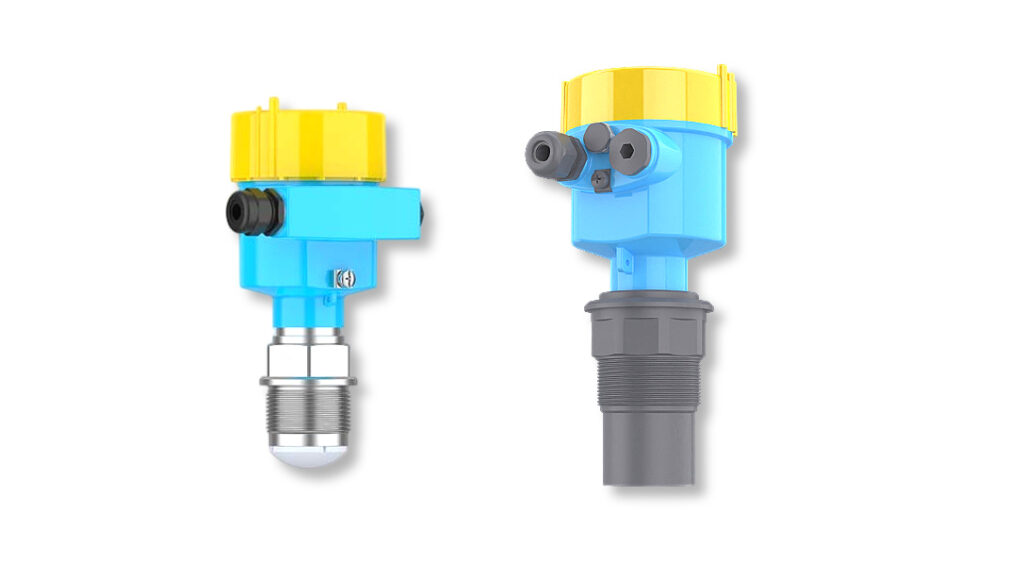

1. Fundamental Physical Differences: Electromagnetic vs. Acoustic Waves

Ultrasonic level meters rely on acoustic wave propagation through air. Their accuracy is highly sensitive to environmental conditions such as temperature, humidity, gas composition, and airflow. Steam, foam, vapor, or strong turbulence can scatter or absorb ultrasonic signals, leading to unstable readings.

Radar level meters, by contrast, use electromagnetic waves, which are largely unaffected by air temperature, pressure, or composition. This provides superior reliability under harsh conditions like condensation, dust, or high humidity. Academic studies confirm that radar achieves higher measurement stability in vapor-saturated or foaming environments compared to ultrasonic technology (Wu et al., 2023).

2. Advances in High-Frequency Radar and FMCW Signal Processing

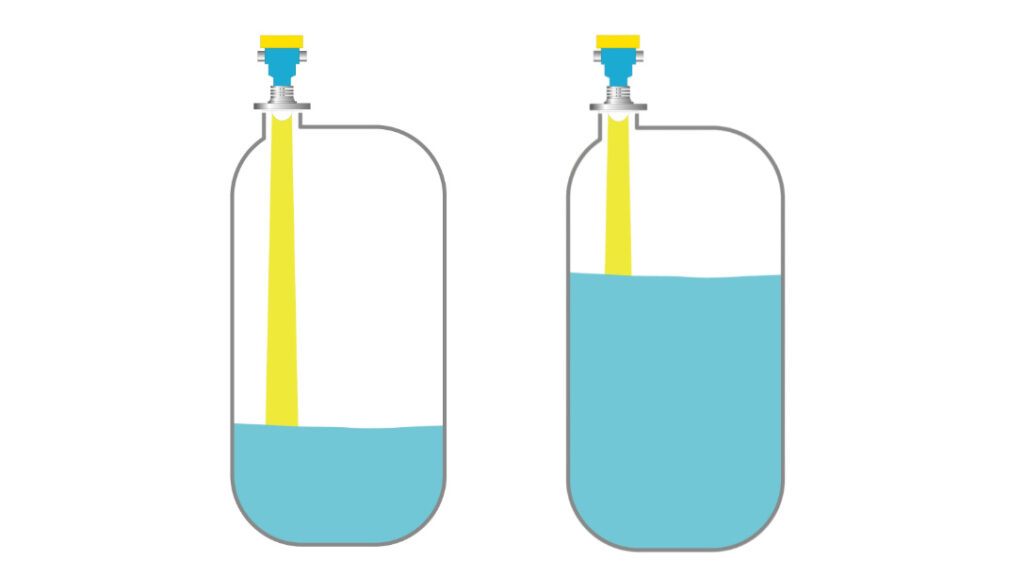

Technological progress in 80GHz radar modules and FMCW signal processing enables narrower beam angles, higher distance resolution, and improved noise rejection. Radar devices can distinguish between multiple reflections, such as tank wall echoes versus actual liquid surface echoes, even in confined or complex vessels.

For low-dielectric-constant media, such as hydrocarbons, modern radar algorithms combined with sensitive antennas allow consistent echo detection, a limitation of earlier radar systems. Research highlights the significant improvements in accuracy and robustness provided by FMCW radar in industrial metrology (Rykunov & Osipov, 2021).

3. Reduction of Dead Zones and Flexibility in Engineering Design

Ultrasonic sensors have a relatively large dead zone near the sensor face, where accurate measurement is impossible. This limits their use in small tanks, short ranges, or installations close to the sensor.

High-frequency radar, particularly 80GHz, dramatically reduces dead zones, allowing flexible installation even in compact tanks. This reduces the need for bypass chambers, stilling wells, or extended sensor mounts, lowering engineering complexity and potential leak points (Li et al., 2020).

4. Superior Tolerance to Foam, Turbulence, and Surface Films

Foam, agitation, or gas layers are significant challenges for ultrasonic sensors, which often fail to penetrate or return stable echoes. Industries such as fermentation, dairy processing, or chemical reaction vessels frequently face these conditions.

Radar systems can penetrate foam layers or differentiate true liquid surfaces based on dielectric properties. Advanced FMCW radar echo analysis can filter out false reflections caused by foam or turbulence, ensuring reliable measurements under dynamic conditions (Guo et al., 2022).

5. Longer Measuring Range and Higher Accuracy

Radar maintains high accuracy across longer ranges (from several meters to tens of meters) with minimal signal degradation. Ultrasonic waves disperse over distance, and temperature variations further reduce measurement precision.

For bulk solids and large storage silos, radar is preferred due to its ability to maintain accuracy beyond 50 meters. Comparative studies demonstrate that radar consistently outperforms ultrasonic sensors in large-scale applications (Zhang et al., 2021).

6. Integration with Digital Communication and Predictive Maintenance

Modern radar level meters feature advanced digital signal processing, built-in diagnostics, and communication protocols such as HART, Modbus, Bluetooth, and cloud connectivity. These allow remote monitoring, predictive maintenance, and firmware updates.

While some ultrasonic devices have adopted digital features, radar generally provides superior diagnostics, such as echo curve visualization and self-check functions. This aligns with the increasing adoption of smart instrumentation and Industry 4.0 frameworks (Liu et al., 2022).

7. Lifecycle Cost Considerations and Market Adoption Trends

Historically, radar was more expensive than ultrasonic, restricting adoption to critical applications. However, mass production of radar chipsets and integrated antennas, along with standardization of FMCW designs, has reduced costs.

Considering total cost of ownership (TCO), reduced maintenance, fewer false alarms, and avoidance of unplanned shutdowns make radar more economical over its service life. Market surveys show radar adoption rising, while ultrasonic remains competitive mainly in simple or budget-sensitive applications (Wang & Chen, 2020).

8. Practical Selection Guidelines

- Radar level meter is recommended for:

- Tanks with steam, vapor, or condensation

- Vessels with foam, agitation, or turbulence

- Long measuring ranges (≥10 m) or large silos

- High-reliability applications in chemical and energy industries

- Remote or hazardous sites where maintenance access is limited

- Ultrasonic remains suitable for:

- Open channels or weirs in wastewater management

- Small-scale, cost-sensitive projects with stable conditions

- Non-critical measurements where occasional signal loss is acceptable

- Hybrid strategies: Use radar for critical tanks and ultrasonic for secondary measurements to balance cost and performance.

9. Radar vs Ultrasonic Quick Comparison Table

| Feature | Ultrasonic Level Meter | Radar Level Meter |

|---|---|---|

| Principle | Acoustic waves | Electromagnetic waves (microwave) |

| Environmental Sensitivity | High (temperature, humidity, foam, vapor) | Low (stable under steam, dust, foam) |

| Dead Zone | Large | Minimal (especially 80GHz) |

| Measuring Range | 0.3–15 m typical | 0.5–120 m (bulk solids, silos) |

| Accuracy | ±5–10 mm | ±1–5 mm |

| Maintenance | Moderate to high | Low |

| Digital Integration | Limited | Advanced (HART, Modbus, Cloud) |

Conclusion

Radar level meters are gradually replacing ultrasonic sensors due to robustness, accuracy, long-range capability, and smart integration. While ultrasonic devices remain suitable for simple, short-range, or budget-conscious applications, radar has become the preferred solution in complex, critical, or harsh industrial environments.

References (APA Style)

- Guo, H., Sun, Y., & Zhang, L. (2022). Radar-based liquid level measurement under foam and agitation conditions. Measurement, 195, 111128. https://doi.org/10.1016/j.measurement.2022.111128

- Li, J., Zhao, Q., & Wang, H. (2020). Design and application of 80 GHz FMCW radar level sensors in small tank measurement. IEEE Sensors Journal, 20(15), 8543–8551. https://doi.org/10.1109/JSEN.2020.2986735

- Liu, Y., Chen, X., & Zhou, D. (2022). Smart instrumentation for Industry 4.0: Radar level sensors with digital diagnostics. Journal of Process Control, 114, 24–34. https://doi.org/10.1016/j.jprocont.2022.02.006

- Rykunov, M., & Osipov, A. (2021). FMCW radar for industrial metrology: Advances and challenges. Sensors, 21(14), 4829. https://doi.org/10.3390/s21144829

- Wang, T., & Chen, Y. (2020). Comparative analysis of radar and ultrasonic level measurement technologies in industrial process control. Instrumentation Science & Technology, 48(7), 627–643. https://doi.org/10.1080/10739149.2020.1718456

- Wu, Z., Yang, J., & Huang, P. (2023). A review of non-contact radar level measurement in industrial applications. Water, 15(18), 3233. https://doi.org/10.3390/w15183233

- Zhang, F., Liu, J., & Gao, M. (2021). Application of millimeter-wave radar in large silo level measurement. IEEE Transactions on Instrumentation and Measurement, 70, 1–9. https://doi.org/10.1109/TIM.2021.3054572