Professional Analysis of Primary Instruments, Secondary Instruments, and Field Instruments

Primary Instruments, Secondary Instruments, and Field Instruments: A Professional Overview

In modern industrial production, automated detection and control systems are essential for maintaining process stability, improving efficiency, and ensuring safety. Instruments, as a critical component of process control systems, perform key tasks such as measurement, display, transmission, and recording. Depending on their function and installation location, industrial instruments are typically categorized as primary instruments, secondary instruments, local instruments, and remote transmission instruments. Each type plays an indispensable role within industrial automation systems. Proper selection and combination of these instruments can significantly enhance process safety, reliability, and automation levels.

Primary Instruments: The Core of Process Parameter Sensing

Primary instruments are directly in contact with the measured medium and are usually installed on process pipelines, equipment, or near measurement points. Their main function is to detect changes in process parameters and perform the first energy conversion, outputting corresponding physical quantities or signals. Some primary instruments can display the measured value directly, while others only provide signals for downstream processing. Typical primary instruments include thermocouples, orifice flow devices, vibrating rod (fork) level switches, and rotary paddle level switches. Primary instruments form the foundation of industrial automated measurement systems, serving as the sensing core at the forefront of the measurement chain.

Secondary Instruments: Signal Reception and Centralized Control

Secondary instruments receive signals from primary instruments or transmitters, including electrical or pneumatic signals, and provide indication, recording, or accumulation of process parameters. They perform the second energy conversion of the signal and are commonly used for centralized monitoring in control rooms. Input signal types for secondary instruments typically include pneumatic signals (20–100 kPa), type II electrical signals (0–10 mA DC), and type III electrical signals (4–20 mA DC). By using secondary instruments, operators can monitor and control production processes in real time from the control room, enhancing operational safety and process control.

Local Instruments: On-site Direct Operation

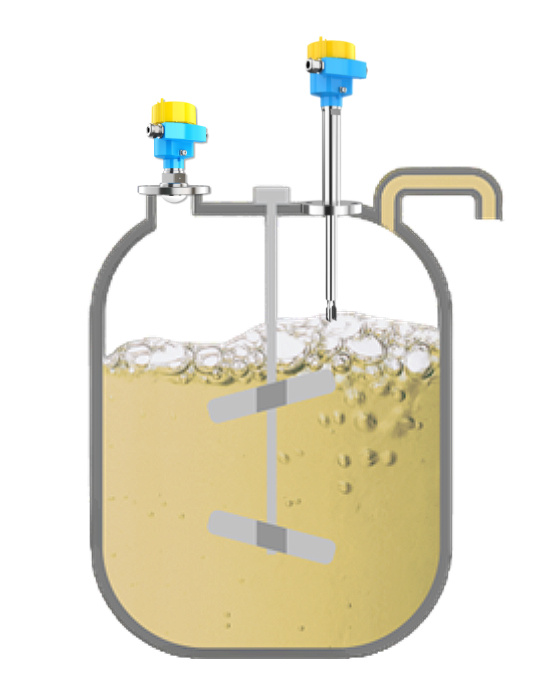

Local instruments are installed near production equipment at the site, allowing operators to directly read measurements on the spot. Common local instruments include glass tube level gauges, magnetic level indicators, radar level meter and standard pressure gauges. Their main advantage is providing intuitive and convenient readings, enabling operators to quickly assess process conditions. Local instruments are particularly useful for real-time operations or as a reference during emergency interventions.

Remote Transmission Instruments: Centralized Monitoring and Remote Control

Remote transmission instruments transmit field measurements as electrical or pneumatic signals to control rooms, enabling remote monitoring and centralized control. Typical instruments in this category include level meters, pressure transmitters, and temperature transmitters. Often, local indication and remote transmission functions are combined: local display supports emergency operations and backup in case of control system failure, while remote transmission ensures centralized monitoring and automatic control. This combination improves overall automation, operational efficiency, and safety.

Conclusion

Primary, secondary, local, and remote transmission instruments together form a complete industrial automation measurement system. Primary instruments sense process parameters and output signals, secondary instruments receive and display these signals centrally, local instruments provide intuitive on-site operation, and remote transmission instruments enable centralized monitoring and remote control. By carefully selecting and combining these instruments, industrial facilities can ensure process stability, enhance system reliability, and improve overall automation, providing a solid technical foundation for modern industrial production.