Level Assurance under Extreme Conditions: JIWEI Spin-11 Rotary Paddle Level Switch in 600 kA Electrolytic Cells

📜 Abstract

Rotary paddle level switches play a crucial role in the extreme working conditions of aluminum electrolysis. This article details the selection, application, and results of the aluminum oxide feed bin level monitoring system for Hengxin Aluminum’s 320,000 ton per year electrolytic aluminum project. The operational environment is extremely complex, facing multiple challenges: high temperatures (20°C to 200°C), strong magnetic fields (up to 1000 Gs), heavy dust, and corrosive gases. By utilizing JIWEI‘s specialized high-performance rotary paddle level switch (Spin-11 Series), the project successfully achieved accurate, real-time monitoring of aluminum oxide levels in the potline bins, ensuring stable operation and automated feeding control for the 600 kA electrolytic cells.

I. Project Overview and Process Challenges

1. Hengxin Aluminum’s 320,000 Ton Electrolytic Aluminum Project

This project is Hengxin Aluminum’s core initiative for expanding capacity and upgrading technology, adopting advanced 600 kA large prebake anode technology. The procurement volume for the rotary paddle level switches is substantial (totaling 360 units), used to monitor the aluminum oxide inventory in the feed bins located above each electrolytic cell (at both the metal tapping end and the flue gas end). The switch’s core function is to provide real-time “full/empty” status feedback to the Pot Control Unit (SCC), guiding the feeding process to ensure stable electrolysis and maximize current efficiency.

2. Instrumentation Selection Challenges

Aluminum electrolysis is characterized by “three highs” (high temperature, high current, and high pollution). The operational conditions for all instruments installed in the superstructure area of the electrolytic cells present severe challenges:

- High Temperature Environment: Although the general workshop temperature is 20°C to 55°C, the working temperature in the cell superstructure area reaches 20°C to 200°C—requiring high-temperature resistance for all components, especially seals, to prevent premature failure.

- Strong Magnetic Field Interference: The 600 kA DC current generates an intense magnetic field of up to 1000 Gs around the cells. The magnetic field can interfere with the precision electronic components inside the switch, such as the motor, gearbox, and relay, potentially leading to rotation failure, false trips, or severely shortened lifespan.

- Corrosion and Dust: The presence of aluminum oxide dust, CO, CO₂, and trace amounts of highly corrosive HF (Hydrogen Fluoride) gas demands superior protection rating, sealing, and materials with excellent corrosion and dust resistance.

- Insulation Requirement: Since the electrolytic cell is energized, the level switch must be reliably electrically isolated from the feed bin flange to prevent current leakage. The insulation resistance is required to be no less than 2 MΩ.

II. JIWEI Spin-11 Rotary Paddle Level Switch: Key Technical Breakthroughs

To address these challenges, Hengxin Aluminum ultimately selected the Spin-11 Series rotary paddle level switch provided by JIWEI, a company with extensive experience in the aluminum industry. This product incorporated multiple customized designs specifically for the aluminum electrolysis application.

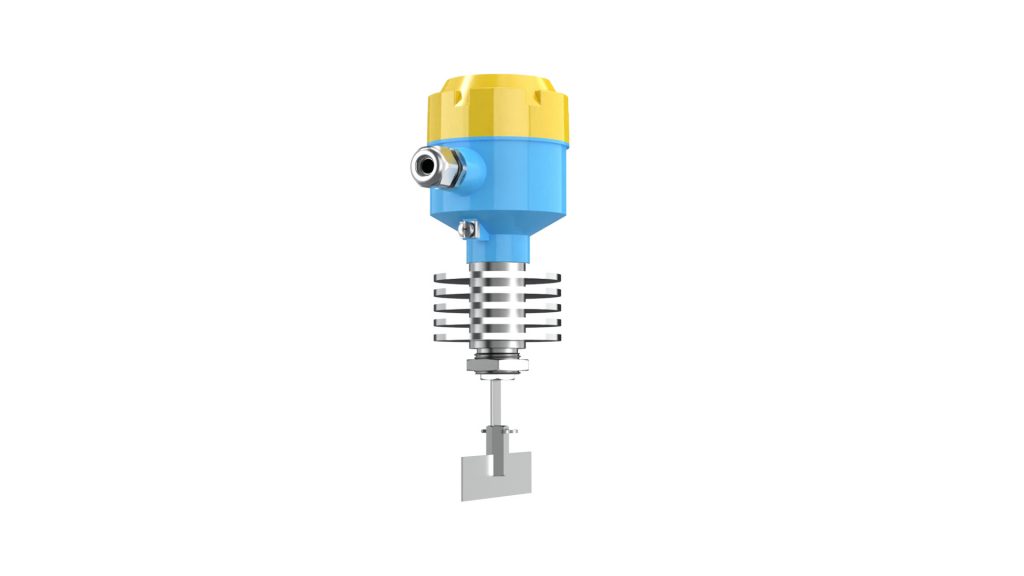

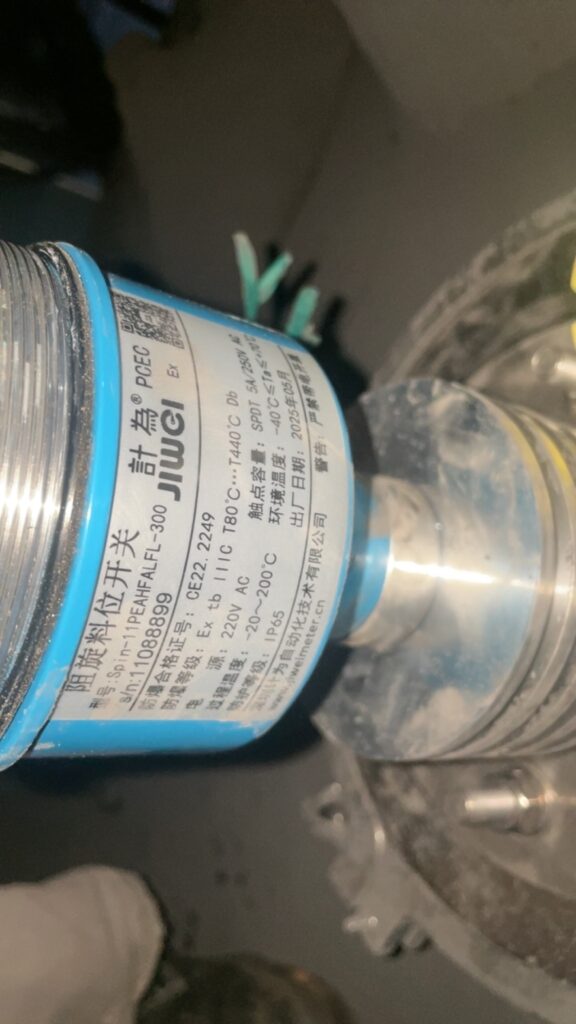

JIWEI Spin-11 Rotary Paddle Level Switch

1. Superior Temperature Resistance and Sealing Design

- High-Temperature Materials: For the long-term operating environment of 200°C, the critical components of the Spin-11 Series (flange, outer pipe and shaft, and paddle) are all made of high-strength, corrosion-resistant 304 Stainless Steel.

- Customized High-Temperature Sealing: The core seals, bearing lubricants, and gearbox oil seals were selected to be specialized materials rated for temperatures ≥ 400°C. This robust design ensures the device maintains its IP65 protection rating even at high temperatures, effectively preventing the ingress of aluminum oxide dust and corrosive gases, significantly extending the product lifespan.

2. Strong Magnetic Field Shielding and Anti-Interference Technology

- Magnetic Shielding Design: To counteract the 1000 Gs strong magnetic field, JIWEI utilized a specialized magnetic shielding cover over the motor drive and signal output modules of the Spin-11. This successfully isolates the external magnetic field, protecting the internal permanent magnet motor from interference and ensuring the paddle speed remains stable at 1 RPM.

- High-Reliability Relay Output: The output uses a SPDT (Single-Pole Double-Throw) relay switch, with a contact capacity of 5 A/250 VAC, ensuring the level status is transmitted to the SCC stably and without interference.

3. Structural and Electrical Compliance

- Critical Dimension Matching: The device insertion depth is precisely designed at 350 mm, perfectly matching the bin structure to ensure accurate level detection.

- Insulation Implementation: The supplier provided customized high-temperature insulation gaskets and insulating bolt sleeves for installation between the switch flange and the bin flange. On-site testing confirmed the insulation resistance meets the technical requirement of no less than 2 MΩ.

- Electrical Specifications: The operating voltage is 220 VAC, with a low power consumption of only 5 W. The IP65 cast aluminum junction box ensures wiring safety and dust resistance, and comes with a connecting cable length of 1.5 m.

III. Implementation and Operational Benefits

1. Supply and Technical Guidance

The project involved supplying a total of 360 Spin-11 Series rotary paddle level switches. JIWEI strictly adhered to the contract requirements, completing the full delivery to the designated domestic location within two months.

Upon equipment arrival, JIWEI dispatched experienced technical personnel to provide remote installation guidance, ensuring the correct placement of insulation components and wiring according to design specifications. The technicians specifically advised site operators on how to properly secure cables and avoid mechanical impacts in the strong magnetic field environment to minimize human error and damage.

2. Operational Performance and Quality Assurance

Since commissioning, the Spin-11 Series rotary paddle level switches have demonstrated exceptionally high reliability and stability in the harsh environment characterized by heavy dust, strong magnetic fields, and high temperatures.

This system’s performance translates into clear operational benefits:

Since installation and operation, the Spin-11 Series level switches have demonstrated exceptional reliability and stability in the harsh environment of high dust, strong magnetic fields, and high temperatures. This is specifically reflected in multiple aspects: First is stable operation, as the device successfully achieves real-time, precise monitoring of the aluminum oxide bin level. The Pot Control Unit can accurately determine the necessity of feeding operations based on the switch signal, thereby effectively maintaining the stable thickness of the aluminum oxide crust in the cell, which provides fundamental assurance for optimizing current efficiency. Second is the significant reduction in maintenance costs; due to its superior sealing and anti-interference capabilities, the switch’s unplanned downtime failure rate is far below the industry average, greatly alleviating the maintenance workload and operational costs in the potline. Finally, through the quality commitment, Hengxin Aluminum and JIWEI signed a long-term three-year warranty period, which far exceeds industry standards, fully demonstrating the manufacturer’s confidence in its product under high-risk conditions; during the warranty period, JIWEI commits to respond and assist with any quality issues within 24 hours of notification, providing strong assurance for the user’s long-term operation.

IV. Conclusion

The successful application of the JIWEI Spin-11 Rotary Paddle Level Switch in the Hengxin Aluminum 600 kA project showcases its outstanding performance and reliability in high-risk, extreme environments. By specifically addressing the core technical challenges of high temperature, strong magnetic fields, high dust, and insulation requirements, the product provides the electrolytic cell automation control system with stable and dependable level foundation data, making it a critical support for enhancing the efficiency and safety of modern aluminum electrolysis production. This successful application serves as an important reference case for other large-scale electrolytic aluminum projects when selecting level monitoring equipment for demanding conditions.