How to Choose the Right Radar Level Transmitter? Insights from a Instrumentation Engineer

A Valuable Field Note from Chief Engineer Li

We recently received a practical and insightful submission from Mr. Li, Chief Engineer at a chemical plant with over 20 years of experience in instrumentation maintenance. His firsthand knowledge is invaluable, so we’re sharing it here to benefit more professionals in the field.

Radar Level Transmitters vs. Ultrasonic: Why Radar Wins in Versatility

In day-to-day maintenance, two types of non-contact level measurement instruments are most commonly seen on-site: ultrasonic level transmitters and radar level transmitters. Among the two, radar level transmitters are more widely used due to their greater adaptability. Whether it’s an open tank or a sealed vessel, measuring liquids, solids, or slurries, radar performs reliably with less maintenance.

However, with so many radar options on the market, it can be hard to choose the right one. Based on years of field experience, I’d like to share some thoughts on how different radar frequency bands perform in real-world applications—and when to use which.

Low-Frequency Radar (6–10 GHz): Rugged and Affordable

Pros:

- Excellent performance in harsh conditions such as dust, steam, or condensation.

- Ideal for environments like ash silos in power plants or cement silos.

- Cost-effective and durable.

Cons:

- Broad beam angle means lower measurement precision.

- Sensitive to internal obstructions like agitators.

- May require additional structures like stilling pipes or angle adjustments.

Use Case:

When budget is tight and the environment is rough, low-frequency radar is still a go-to solution.

Mid-Frequency Radar (24–26 GHz): The Workhorse of the Industry

Pros:

- Good balance between precision and cost.

- Commonly used in petrochemical tanks and standard process vessels.

- Stable when site conditions are moderate.

Cons:

- Struggles in tanks with heavy vapor or foam.

- May require periodic cleaning or repositioning of the antenna.

Use Case:

Best suited for medium-complexity applications where extreme accuracy or harsh environments are not key concerns.

High-Frequency Radar (76–81 GHz): Precise but Sensitive

Pros:

- Millimeter-level accuracy.

- Excellent for high-precision applications like pharmaceutical raw material tanks.

- Smaller beam angle allows for easier installation in narrow tanks.

Cons:

- More sensitive to foam, suspended solids, and installation position.

- Requires skilled technicians for setup and tuning.

- Higher initial investment.

Use Case:

When precision is non-negotiable and budget allows for a high-end solution, high-frequency radar delivers outstanding results.

Example: In one case, after a formula change increased foam levels in a tank, the high-frequency radar became unstable. It took several days of adjustments to restore performance.

Dual-Frequency Setup: Combining Strengths for Complex Environments

In a recent project involving a new ash handling system, we started with low-frequency radar for its strong dust penetration. However, precision was lacking. We then added a high-frequency radar unit to measure the actual level more accurately.

Result:

- Stable, accurate measurement despite the challenging environment.

- Fewer unplanned shutdowns.

- Higher initial cost, but lower long-term risk and loss.

This multi-frequency approach proved to be a smart investment.

Final Thoughts: Practical Tips for Choosing the Right Radar

- Don’t just trust the spec sheet.

Real-world conditions often differ from what’s written in the brochure. Field experience is key. - Know your tank and medium.

Consider tank structure, material properties, temperature, pressure, and humidity. - Choose a trusted manufacturer.

After-sales support and technical know-how are critical, especially for high-frequency systems. - Trial first, buy later if possible.

Testing a few units on-site can save time, cost, and frustration in the long run.

Case Highlight:

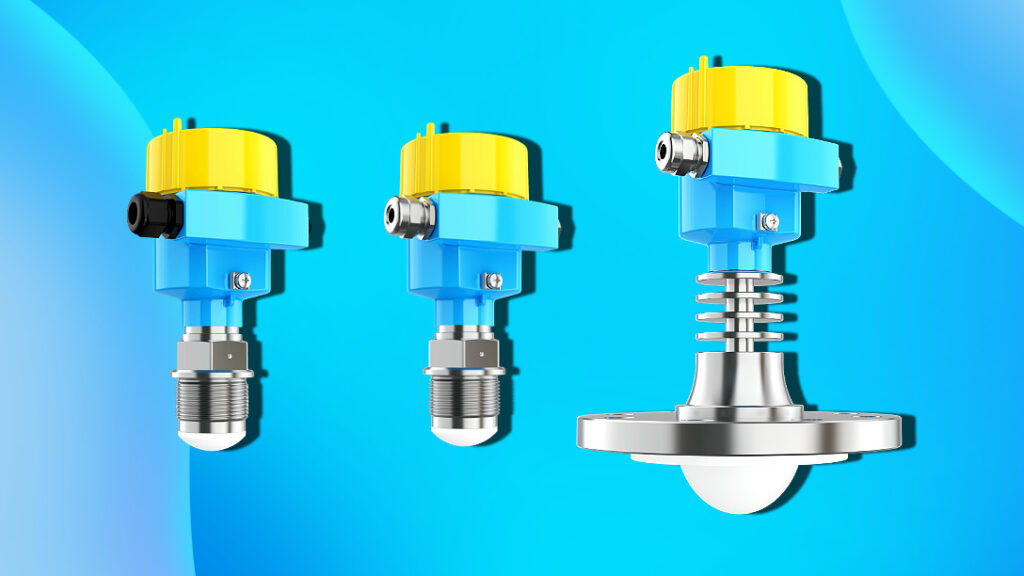

Jiwei Radar Level Transmitters in Wastewater Treatment

In one chemical plant, Jiwei radar level transmitters were deployed in a foam-heavy wastewater tank. Thanks to their high-frequency wave penetration capabilities, the transmitters provided stable and accurate readings despite agitation and thick foam layers—proving that not all radar is created equal.