Safety Barriers and NAMUR Standards

Introduction: Explosion Safety in Industrial Automation

In modern industrial automation, explosion safety is always a top design priority. Whether in chemical plants, oil and gas platforms, pharmaceutical factories, or mining systems, any presence of flammable gases or dust requires strict control of electrical energy to prevent accidents. Among numerous explosion-proof measures, a small yet critical device often overlooked determines whether a system can truly operate safely—the safety barrier. Compact but essential, it serves as the “last line of defense” in intrinsic safety systems, maintaining energy and signal balance between hazardous and safe zones.

What is a Safety Barrier—The Gatekeeper of Signals and Energy

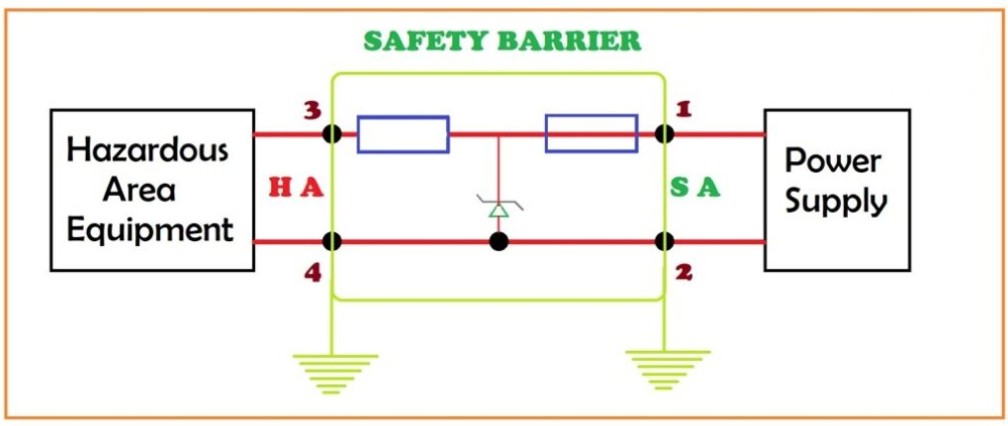

A safety barrier prevents hazardous energy from passing from the safe area into the hazardous area. Typically installed at the interface between these zones, one side connects to the control system, and the other connects to field instruments. Its main function can be summarized as: “Allow signals to pass, stop dangerous energy.” By strictly limiting voltage and current entering the hazardous zone, safety barriers ensure that even if a system fails, sparks or excessive heat sufficient to ignite flammable substances cannot occur.

Safety barriers are mainly divided into Zener barriers and isolated barriers. Zener barriers use Zener diodes, resistors, and fuses to limit voltage and current, while isolated barriers add optical, electromagnetic, or transformer isolation to completely separate signal and energy, enhancing overall system reliability.

Zener Barriers: Classic and Reliable “Triple Protection”

Zener barriers are the earliest and simplest type. Their operation involves three layers of protection: voltage limitation via Zener diode, current limitation via series resistor, and circuit interruption via fuse during severe faults. Zener barriers are fast, cost-effective, and straightforward, but their effectiveness depends on proper grounding. If grounding is insufficient or resistance is too high, voltage clamping fails, weakening explosion-proof protection. Proper grounding is thus critical to ensuring intrinsic safety in practical engineering.

Isolated Barriers: Intelligent Signal Protection

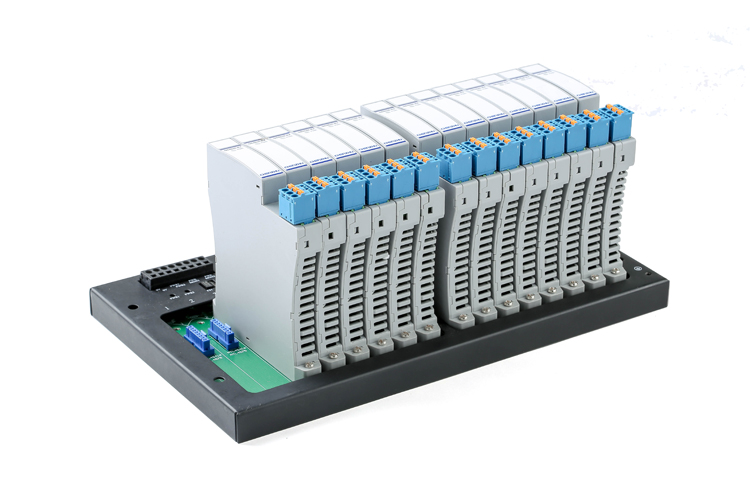

As industrial systems become more complex, isolated safety barriers have emerged. In addition to voltage and current limiting, isolated barriers achieve complete separation of input, output, and power using optical, electromagnetic, or transformer coupling. This resolves ground loop interference and signal crosstalk.

Advantages of isolated barriers include no grounding requirement, flexible installation, strong anti-interference capability, high signal stability, and compatibility with various signal types such as current, voltage, frequency, thermocouples, and RTDs. They also support one-to-two signal distribution, offering high accuracy and long-term stability, making them essential in modern PLC and DCS systems.

NAMUR Standards: The Common Language for Global Explosion-Proof Systems

If safety barriers are the “hardware guardians” of explosion-proof systems, NAMUR provides the standardized “language rules” worldwide. NAMUR (Normenarbeitsgemeinschaft für Mess- und Regeltechnik in der Chemischen Industrie) was founded in 1949 in Germany and is a leading users’ association in industrial automation. Its NE series recommendation documents are widely referenced in IEC, EN, and national explosion-proof standards.

NAMUR standards ensure compatibility among safety barriers, transmitters, and control systems. Key related standards include NE21 (signal interference and surge protection), NE43 (4–20mA analog signal fault states), NE44 (loop break and short-circuit detection), NE89 (intrinsic safety system selection principles), and NE95 (device diagnostics and communication interface requirements). These guidelines allow control systems to accurately interpret device status and maintain reliable signal diagnostics.

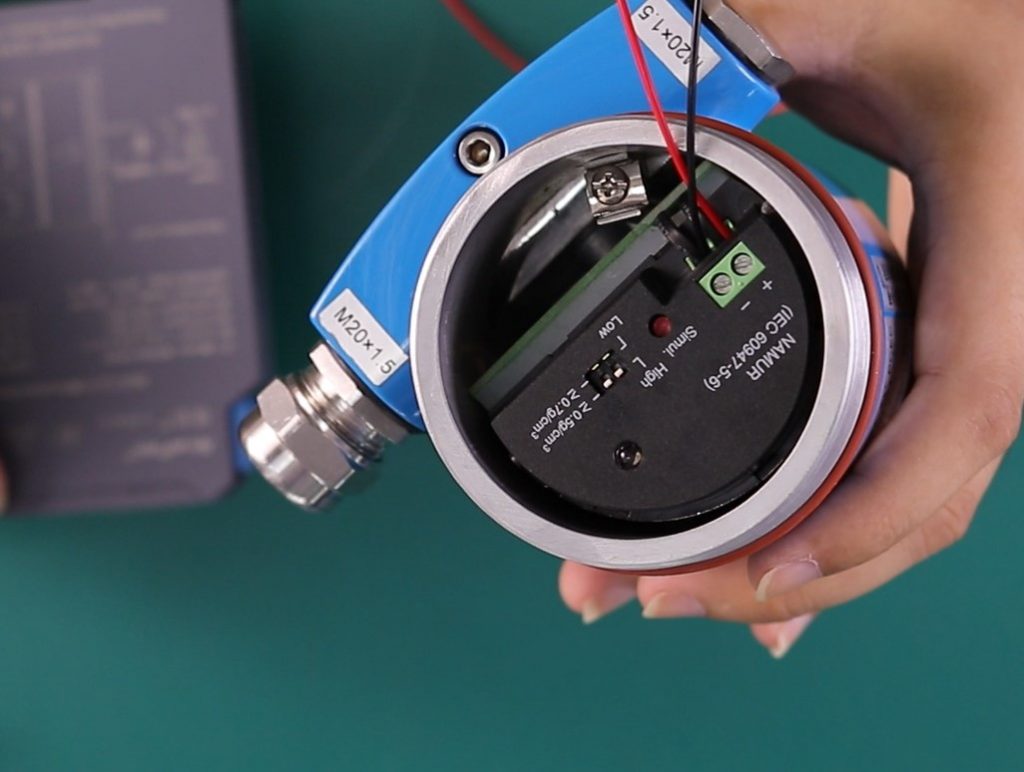

NAMUR Sensors and Safety Barriers: The Golden Combination for Intrinsic Safety

NAMUR two-wire sensors produce very low current (typically ~1mA) and must be used with safety barriers for safe and stable transmission to control systems. In modern chemical, pharmaceutical, and petrochemical facilities, the combination of NAMUR sensors and safety barriers has become the standard intrinsic safety signal chain, ensuring operational safety, data accuracy, and system reliability.

Selecting and Installing Safety Barriers

Correct selection and installation are critical to intrinsic safety. Selection requires identifying the signal type (AI, AO, DI, DO), confirming the explosion-proof rating (Exia/Exib), checking intrinsic safety parameters (Uo≤Ui, Io≤Ii, Po≤Pi), choosing NAMUR NE21/NE43-certified products, and verifying channel count and installation method.

During installation, Zener barriers must be properly grounded (≤1Ω), isolated barriers should have sufficient ventilation and spacing to prevent overheating, signal and power cables should be segregated, terminals clearly labeled for safe and hazardous zones, and polarity verified before commissioning. These practices maximize signal protection and explosion-proof performance.

Application Example: Silent Guardians in Chemical Plants

In a fine chemical plant’s reactor temperature monitoring system, engineers implemented isolated safety barriers combined with temperature transmitters compliant with NAMUR NE43 standards. Real-world monitoring data revealed that this configuration excels across key performance metrics.

Signal Stability Analysis

During continuous operation, the transmitter output remained within the 4–20 mA range, with signal fluctuation at the system input kept below ±0.1% after isolation by the safety barrier. Even under thunderstorms or high electromagnetic interference, the signal exhibited no drift, ensuring the control system received accurate temperature readings.

By comparison, similar projects without isolated barriers recorded fluctuations of ±0.5–1% during the rainy season, often resulting in false alarms.

Fault Response Capability

When transient overvoltage events occurred (such as compressor start/stop cycles or lightning-induced spikes), the safety barrier’s opto-isolation and current-limiting protection absorbed the abnormal energy instantly, preventing disturbances to downstream PLC or DCS systems.

Operational records showed 12 such voltage or lightning events, with the safety barrier successfully protecting the system each time — zero false actions, zero failures.

Maintenance Cycle and Reliability

Over more than five years of continuous operation, the safety barrier maintained stable signal transmission without requiring replacement or recalibration.

Field maintenance teams reported that isolated barriers significantly reduced downtime caused by wiring faults, saving approximately 30–40 hours of maintenance time annually.

In another petrochemical pipeline monitoring project, NAMUR-type proximity switches paired with safety barriers were used for remote limit detection. From the perspectives of signal transmission and equipment protection:

- Signal Integrity: The isolation provided by the safety barrier prevented interference from motors and pumps near the pipelines. Over years of operation, the system recorded zero false triggering.

- System Safety: The barrier limited any overcurrent or overvoltage entering hazardous areas. Even in the event of sensor failure, no unintentional pipeline shutdowns or false alarms occurred, ensuring operational safety.

- Long-Term Performance: Five years of continuous monitoring data showed signal stability within ±0.2% and zero false operations — performance unattainable with traditional direct wiring.

Technical Summary

Based on real-world data and long-term operation, safety barriers are not merely “protective devices” — they are the backbone of signal reliability in industrial systems. Through electrical isolation, current limiting, and voltage suppression, they shield control systems from external interference and transient faults while ensuring high signal accuracy and reliability.

This is precisely why, in modern chemical, pharmaceutical, and petrochemical facilities, the combination of isolated barriers and NAMUR sensors has become the de facto standard for intrinsically safe signal chains.

Conclusion: Smarter Safety, Reliable Signals

Safety barriers are silent protectors of industrial explosion-proof systems. They do not directly control operations but safeguard every signal; they do not output energy but strictly restrict hazardous energy. NAMUR standards provide consistent rules, enabling global explosion-proof systems to “speak the same language.” In the 4–20mA signal chain, the synergy between safety barriers and NAMUR standards ensures efficient operation while maintaining intrinsic safety, offering reliable, intelligent protection in modern industrial automation.