How to Choose Hydraulic Hoses: Selection, Installation, and Maintenance Guide

How to Choose Hydraulic Hoses

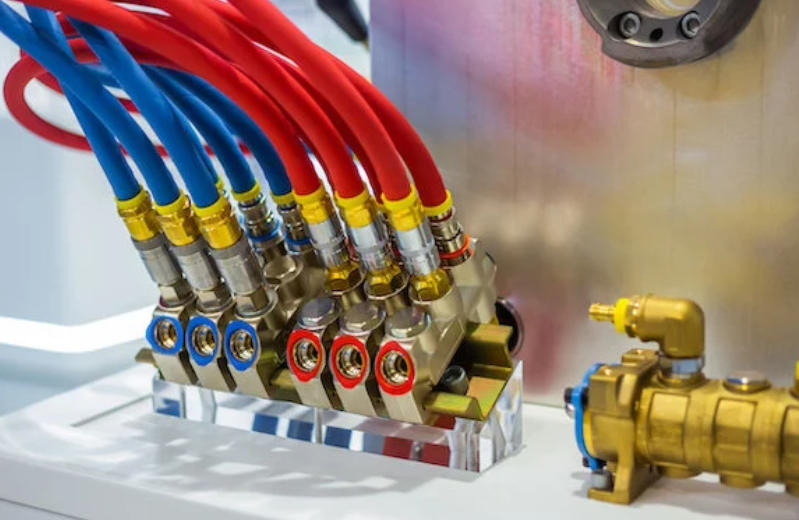

In most automated equipment hydraulic systems, attention often focuses on “core” components such as pumps, valves, and cylinders, while hydraulic hoses are regarded as secondary. In reality, hydraulic hoses play critical roles in transmitting high-pressure fluids, absorbing vibrations, and compensating for movement. Their reliability directly impacts the safety, efficiency, and operational stability of the entire system.

Hydraulic system issues such as leaks, pressure fluctuations, delayed responses, or even hose bursts can lead to downtime, safety hazards, and financial losses. A significant portion of these problems originates from improper hose selection, routing, or maintenance. For designers and maintenance engineers, understanding the structure, performance, and application details of hydraulic hoses is essential.

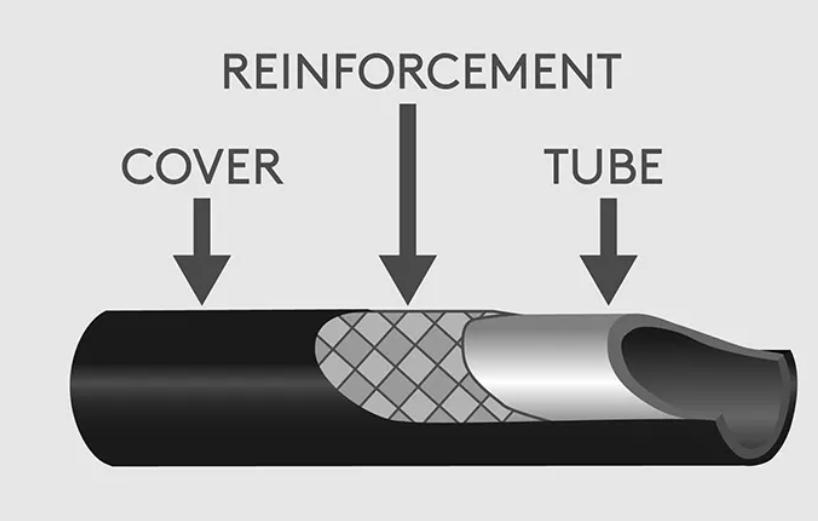

Basic Structure of Hydraulic Hoses

Hydraulic hoses are typically composed of three layers: the inner tube, reinforcement layer, and outer cover.

- Inner tube: Directly contacts the hydraulic fluid, so it must exhibit excellent oil resistance and temperature tolerance.

- Reinforcement layer: Determines the pressure-bearing capacity of the hose. Common types include braided or spiral steel wire, with different structures corresponding to specific pressure ratings.

- Outer cover: Provides protection against UV, ozone, abrasion, and external impacts.

Although the structure seems simple, the material and manufacturing process of each layer affect the hose’s lifespan and performance. In industrial systems, hoses usually comply with standards such as SAE, ISO, and EN. For example, the SAE 100R series defines different hose layer structures and pressure ratings, while ISO 18752 emphasizes overall performance under pulsating or high-temperature conditions. Engineers benefit from knowing which standard a hose conforms to, allowing more accurate assessment of pressure capacity, durability, and suitability for specific applications.

Correct Hose Selection

Selecting a hydraulic hose requires a comprehensive assessment of pressure, temperature, fluid type, bending radius, and installation space. Many field problems arise from considering only the working pressure while ignoring pulsating pressures, environmental temperatures, or bending conditions.

- A hose installed too close to the pump may age faster due to high temperature.

- A hose bent with too small a radius can cause reinforcement layer fatigue and rupture.

- Overly long hoses may amplify vibration and impose abnormal stress on fittings.

- Incompatible fluids can lead to inner tube swelling or hardening.

Proper routing is a professional task that requires evaluating available space, movement directions, pressure fluctuations, and maintenance conditions.

Common Hose Problems

In practice, hydraulic hoses fail in predictable ways. Common issues include:

- Outer layer wear: Often caused by friction against structural components; can be prevented with proper routing or protective sleeves.

- Cracking near fittings: Usually occurs when hoses bend sharply near connectors; straight sections near fittings are recommended.

- Wire corrosion: Outer cover damage allows moisture into the reinforcement, reducing pressure capacity.

- Bursting: Caused by overpressure or fatigue, often due to using hoses with insufficient pressure ratings.

- Rubber aging: High temperature, ozone, and UV exposure can harden or crack hoses, a frequent hidden hazard.

Hose Installation

Proper hose installation requires engineers to follow several key principles:

- Avoid twisting hoses; maintain straight sections near fittings.

- Allow thermal expansion and contraction; avoid extreme movement conditions.

- Prevent long unsupported spans; provide adequate support or restraints.

- Clean the hose interior before installation to avoid contaminants, and use appropriate clamps and torque; avoid hammering fittings.

Hose Maintenance

Hydraulic hoses typically have shorter lifespans than pumps or valves, so systems should incorporate a hose lifecycle management plan.

Regular inspections are essential, focusing on cracks, hardening, bulging, leaks, and exposed reinforcement. Immediate replacement is required when defects appear. For critical equipment, preventive replacement schedules can prevent sudden failures under high-load operation.

Trends in Hose Technology

As equipment pressures increase, hydraulic hose technology continues to evolve. Innovations include higher temperature and pulse-resistant materials, more abrasion-resistant outer layers, lighter structures, and sensors for monitoring hose fatigue. Future hydraulic hoses will not only transmit pressure but also serve as integral components of system health monitoring.

Conclusion

For hydraulic engineers, hose selection, installation, and maintenance are not optional—they are foundational to system reliability. A seemingly ordinary hose can have a far greater impact on overall system performance than expected. Mastering hydraulic hose engineering knowledge significantly enhances system stability, reduces maintenance costs, and improves equipment safety.