Scrubber Phase-Out: The Hidden Shift from Equipment Compliance to Systemic Environmental Control

A Quiet Yet Impactful Decision in Global Shipping

Recently, a seemingly minor decision quietly made waves in the maritime industry.

At a recent meeting, the OSPAR Commission — a marine environmental protection organization in the North-East Atlantic — reached a consensus among 15 European countries: starting in 2027, open-loop scrubbers will be banned in inland waterways and port areas. Two years later, even closed-loop scrubbers will be prohibited.

Shipowners were caught off guard: “What about the millions we’ve invested in exhaust gas cleaning systems? And now we have to pay to dismantle and dispose of them?”

The move by OSPAR may not be aggressive in force, but its direction is clear. Under the banner of marine protection, this is a strategic pushback against the illusion of “pollution control by dilution.”

The message is unmistakable: scrubbers — once a symbol of green compliance — are now under scrutiny by environmental regulation itself.

More importantly, it raises a deeper question for China:

Is environmental protection about large-scale equipment, or is it about mastering complex systems?

1. Scrubbers: Environmental Tool or Disguised Pollutant?

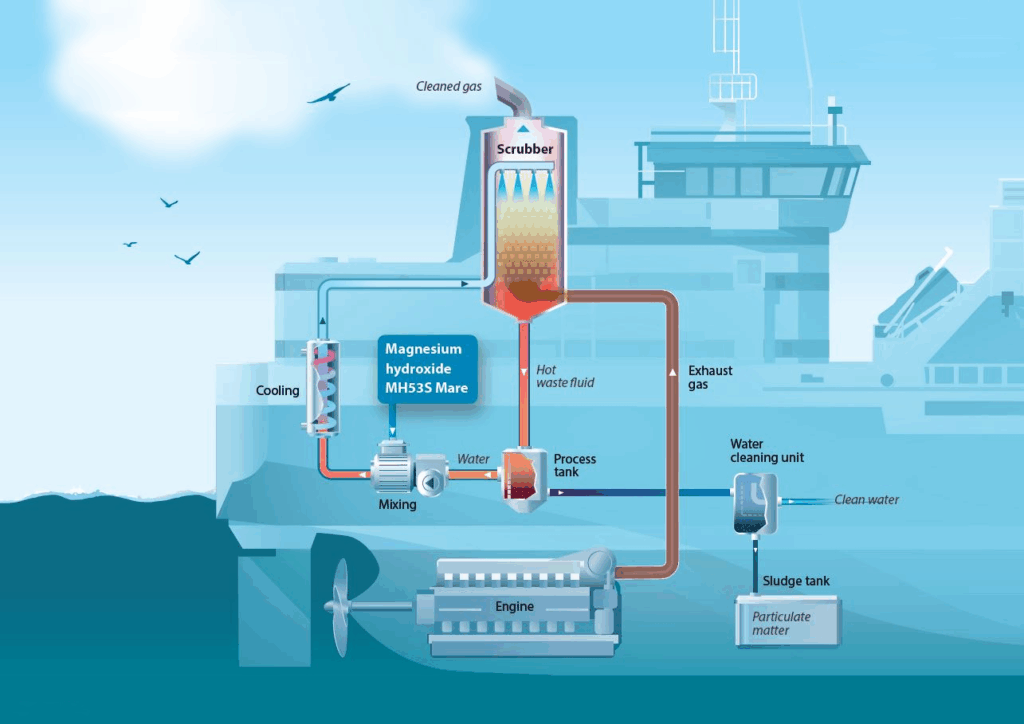

Shipboard scrubbers were originally designed to reduce sulfur oxide (SOx) emissions. Most vessels used to burn high-sulfur fuel oil, releasing heavy sulfur into the atmosphere. In response, the International Maritime Organization (IMO) imposed a global sulfur cap — 0.1% in emission control areas — to protect air quality.

To comply, shipowners installed scrubbers. The most common type is the wet scrubber, which uses alkaline water to wash exhaust gases and remove sulfur. On paper, it sounds environmentally friendly.

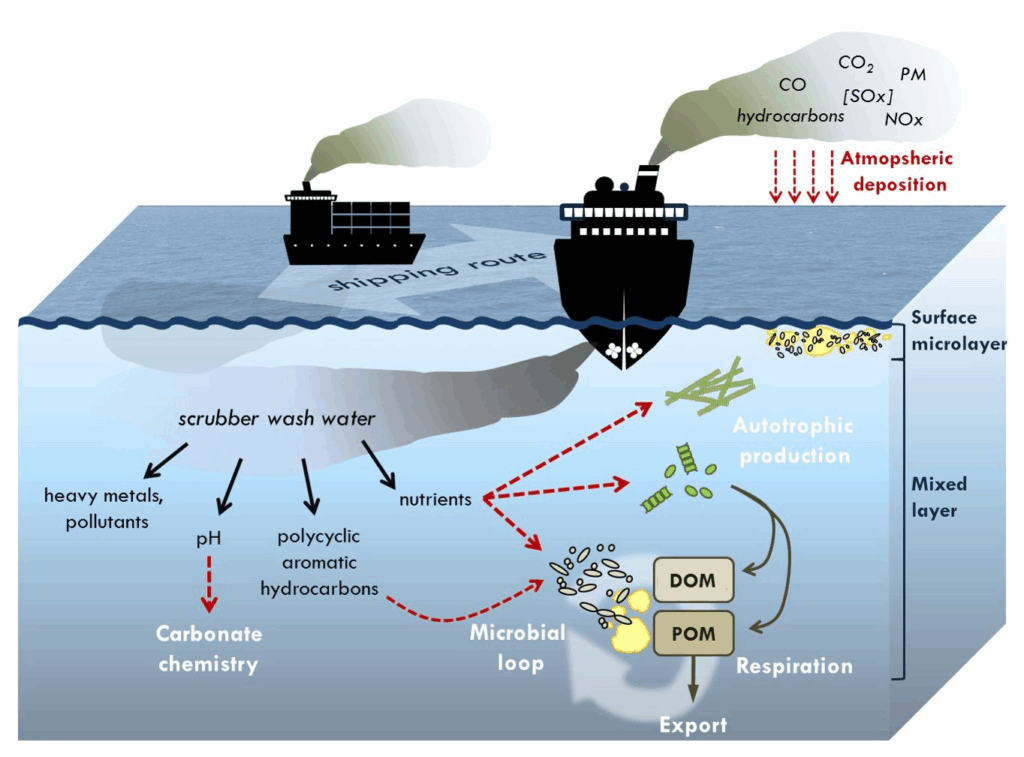

But what happens to the wastewater?

- Open-loop systems discharge it directly into the sea.

- Closed-loop systems recycle it temporarily, but still require eventual discharge.

And what does this water contain?

- Polycyclic aromatic hydrocarbons (PAHs) — carcinogenic;

- Heavy metals — toxic to marine ecosystems;

- Acidic salts — capable of altering ocean pH levels.

In short, we’re shifting pollution from air to water. The medium changes — the pollution remains.

As awareness of this “green loophole” grows, more ports and countries have responded. Canada, Germany, and Sweden, among others, have restricted or outright banned scrubber use in their waters. OSPAR’s recent decision simply formalized what was already an industry concern.

2. For China, the Real Challenge: Equipment or Systemic Control?

China faces a more complex scenario than Europe.

As the world’s largest shipbuilder, China has installed scrubbers across a vast number of new vessels. Shipyards, suppliers, and shipping companies have made heavy investments.

At the same time, China has committed to carbon neutrality (“dual carbon” goals), enforces emission control zones (ECZs), and promotes green port initiatives. Environmental compliance is more than rhetoric — it’s a national mandate.

So, should China phase out scrubbers entirely?

That’s the wrong question. Two common misconceptions must be addressed:

- Does not using scrubbers mean you’re environmentally friendly?

- Does installing scrubbers automatically make you compliant?

The answer to both is no.

The real issue lies deeper: Do you have real-time, precise control over the origin, flow, concentration, and discharge timing of pollutants?

In mature environmental systems, control — not equipment — is the core.

Regardless of whether you use scrubbers, SCRs, or incineration, you need a feedback loop of monitoring → analysis → response. Without it, even the most advanced equipment becomes a “legitimized polluter.”

3. Level and Point Level Instruments: The Industry’s Underrated Control Nerve

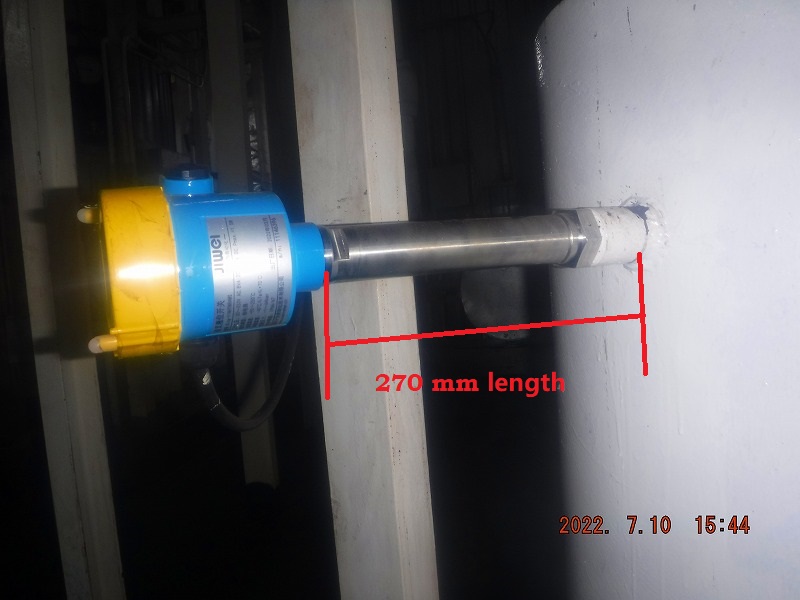

This brings us to two components often overlooked outside the shipping world:

Level transmitters and point level switches.

These “sensors” — often dismissed as auxiliary — are emerging as critical control nodes in next-generation environmental systems.

Because intelligent control begins not with algorithms or cloud platforms, but with accurate data acquisition.

To manage a scrubber system effectively, you must monitor:

- Liquid level in the tank;

- Slurry residue buildup;

- Internal material distribution;

— all of which rely on accurate and robust level detection.

Why Accurate Level Monitoring Matters

Here’s a real-world example:

- If the scrubber water level is too high during operation, it may trigger uncontrolled discharge.

- If residue accumulation is excessive, reaction efficiency drops, leading to pressure imbalance and safety risks.

- If the level sensor fails and operators rely on “experience,” it often results in violations and fines.

Precision is non-negotiable.

A 3% deviation versus a 1% precision margin can mean the difference between regulatory approval and a costly penalty.

Professional sensor manufacturers — especially those specializing in marine-grade level instrumentation — are becoming key enablers in global green shipping.

Their work includes:

- Providing high-accuracy, interference-resistant level measurement;

- Delivering automatic warnings and control feedback under harsh marine conditions;

- Enabling edge computing and cloud integration for remote monitoring and compliance reporting.

What seems like a simple device is, in fact, a gateway to systemic environmental intelligence.

4. The Environmental Battlefield Has Shifted: From Quantity to Precision

The transition away from scrubbers signals more than the end of a device — it marks the beginning of a new paradigm.

Today, industries tied to emissions — shipping, chemical processing, power generation, metallurgy — are entering a “sensing-first” era.

In the past, compliance meant adding more hardware:

Need desulfurization? Install a scrubber.

Need NOx control? Install SCR.

But tomorrow’s standard is:

Do you know — in real time — what’s happening inside your system?

Can you autonomously regulate your emissions?

Do you have a closed-loop feedback control strategy?

That is the true hallmark of a modern environmental framework.

Perception capability — not equipment size — will define who stays in the game.

5. Small Instruments, Big Stakes: Controlling the Future of Green Shipping

Too many still consider level sensors as peripheral tools — like treating the nervous system as a “spare part.”

But in truth, whoever controls the input variables controls the environmental outcome.

In maritime applications, especially, conditions are extreme — corrosion, vibration, turbulence. Scrubber systems, inherently semi-open-loop in nature, are highly dependent on stable and accurate measurement systems.

Even a 5% deviation in level detection can lead to:

- Illegal overboard discharge;

- Process inefficiencies;

- Regulatory penalties and vessel downtime.

Leading domestic instrumentation companies are emerging as critical players in this green transition.

They are focused on:

- Achieving millimeter-level accuracy in liquid and bulk level monitoring;

- Ensuring corrosion-resistant and vibration-proof sensor performance;

- Integrating smart modules for remote diagnostics, edge computing, and regulatory reporting.

This is not just about selling sensors — it’s about offering access to a new generation of environmental control infrastructure.

6. Green Compliance in the Next Era: From Static Devices to Dynamic Systems

The OSPAR decision marks only the beginning. In the coming years, we can expect:

- Scrubber regulations to tighten;

- Loopholes in environmental equipment to close;

- System-level control and data transparency to become mandatory.

The winners will not be those who simply invest in the most equipment, but those who master systemic control.

Two groups stand to benefit:

- Shipowners and solution providers who shift from device-heavy setups to smart, modular architectures.

- High-tech manufacturers rooted in “control endpoints” — companies like Jiwei, delivering intelligent, durable, cloud-enabled sensing platforms.

In this new regime, it’s not about who looks compliant, but who can deliver measurable, real-time, closed-loop control.

Environmental compliance is no longer about optics — it’s about systems that cannot afford to fail.

Those who can build this precision into the smallest margins will hold the key to survival in the era of green shipping.