Shenzhen Jiwei Automations: High-Reliability Level Measurement Technology

In the global process automation landscape, level measurement instruments remain a fundamental component for ensuring production continuity, safety, and operational efficiency. While the industry has long been dominated by a limited number of traditional international manufacturers, a new generation of Chinese engineering companies is emerging—companies that prioritize deep technical capability, independent innovation, and long-term product reliability.

Among them, Shenzhen Jiwei Automations Ltd. has committed to a uniquely focused strategy:

to specialize exclusively in level measurement technologies and to build a fully in-house, end-to-end engineering system—from sensors to algorithms, from hardware design to industrial manufacturing.

This white paper provides a comprehensive overview of Jiwei’s engineering philosophy, product development framework, reliability processes, and industry-tailored innovation approach.

1. Strategic Positioning: Full Vertical Specialization in Level Measurement

Rather than spreading resources across multiple automation categories, Jiwei made an early strategic decision:

to invest exclusively in level switches, level transmitters, and radar-based level measurement instruments.

This choice created several engineering advantages:

- Dedicated technical teams for each product line

- Deep specialization in physical measurement principles

- Unified signal processing architecture for all series

- Shared reliability and environmental testing frameworks

- Long-term accumulation of process-specific know-how

By concentrating on a single measurement discipline, Jiwei established a depth of expertise that is difficult to achieve within diversified instrumentation companies.

2. Independent R&D Architecture: Algorithm, Structure, Circuit, and Process Engineering

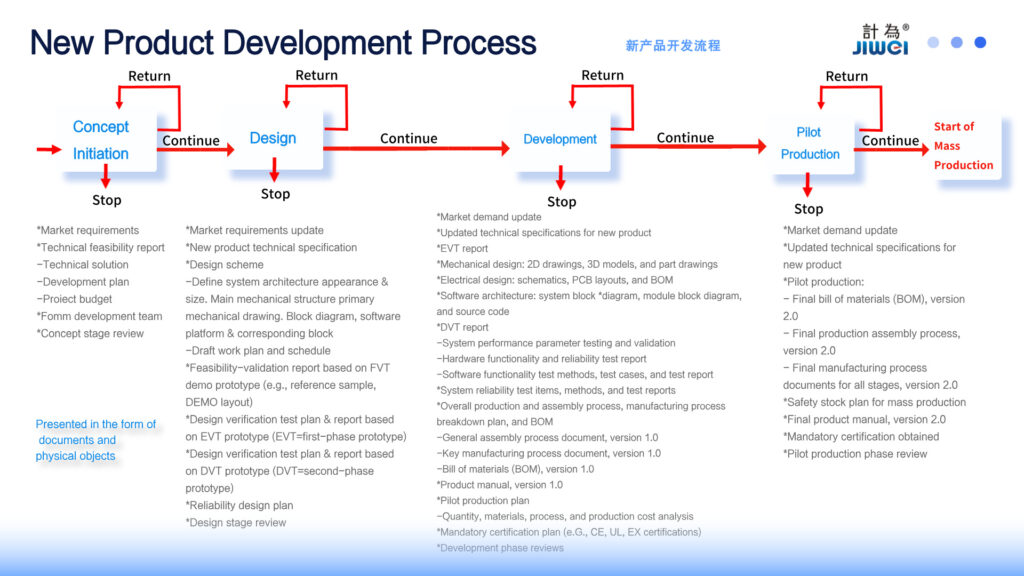

Each product line is supported by an independent R&D team with specialized roles in algorithms, mechanical design, circuitry, and manufacturing processes. Jiwei has also established a complete end-to-end development framework covering every stage from project initiation to mass production. The workflow includes:

Requirement Analysis & Process Modeling:

Based on Jiwei’s industrial application database and field feedback, product managers, algorithm engineers, and field engineers jointly define technical requirements and analyze process characteristics, forming the initial technical specification.

Integrated Design of Structure, Electronics, and Algorithms:

Mechanical structures, PCB layouts, and microwave/vibration signal-processing algorithms are developed concurrently to ensure optimal compatibility between the probe, electronics, and firmware.

DFMEA/RFMEA Risk Assessment:

Every new design must undergo design and reliability failure mode analysis to identify potential failure points and prepare preventive measures in advance.

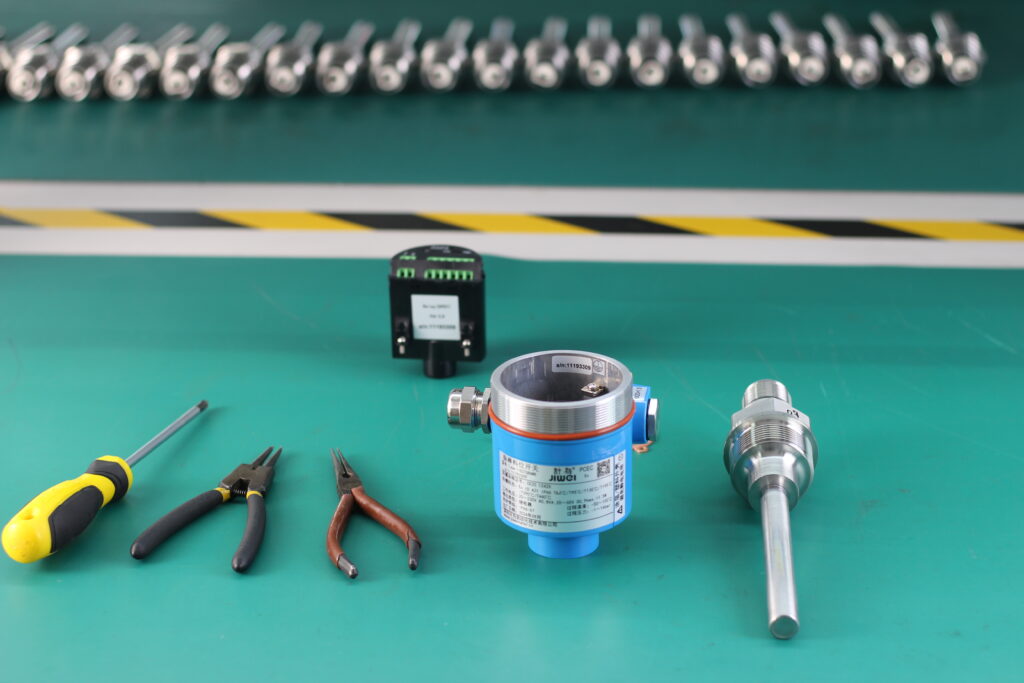

Process Prototyping and Small-Batch Verification:

Prototype stages include probe welding, sealing processes, antenna tuning, microwave echo testing, and calibration workflow debugging, resulting in complete manufacturing process documentation.

Laboratory Verification Testing:

Comprehensive testing includes high–low temperature cycling, temperature–humidity aging, salt-spray corrosion, vibration and shock tests, EMC immunity, electromagnetic compatibility checks, media simulation, and dust/steam interference verification.

Software and Firmware Testing:

The algorithm team conducts signal stability tests, false-trigger analysis, echo curve simulation, and UI stress tests to ensure firmware stability under extreme operating conditions.

Bluetooth / Communication Protocol Validation (for Radar Level Instruments):

Tests include Bluetooth link stability, pairing latency, and protocol compatibility to ensure genuine, reliable performance across different phones and operating systems.

Field Application Testing:

Products are validated in real customer environments—such as high viscosity, heavy dust, high temperature, strong corrosion, and strong vibration—while long-term operational data is collected to generate a comprehensive Field Validation Report.

Reviews and Iterations:

Each stage includes formal reviews: design review (DR), process review (PR), and trial-run review (TR), ensuring full technical closure before mass production.

Stop-Gate Mechanism:

Critical “stop gates” are embedded throughout the process. Any failure in testing requires the project to pause and return to the previous stage for redesign or optimization, preventing immature products from entering the market.

Mass Production Introduction & Quality Control:

Through equipment calibration, automated test platforms, production-line burn-in testing, and batch sampling mechanisms, Jiwei ensures product consistency and long-term reliability across all production batches. Control every performance-critical detail within its instruments.

3. A Closed-Loop Development Process: From Concept to Mass Production

Level measurement instruments are not laboratory devices—they are “safety guardians” operating directly on industrial equipment. They must work, stay stable, and remain reliable over long periods of continuous operation.

Based on this principle, Jiwei has adhered to the highest standards in design, materials, algorithms, and testing from the very beginning:

- High-grade stainless steel (316L) is used for all structural components to ensure long-term durability in corrosive, humid, and high-impact environments.

- Probe designs prioritize process compatibility and robustness, with structural optimizations for challenging conditions such as viscous media, buildup, low dielectric constants, and heavy dust.

- Signal-processing chips and algorithms are fully in-house developed, enabling accurate identification and filtering of foam, steam, disturbances, weak echoes, and other complex signal patterns.

- A fully automated testing workflow and long-duration aging procedures are applied throughout production to ensure that every device undergoes comprehensive stability verification before shipment.

- Specialized versions are developed for extreme applications, including high-temperature, strong corrosion, high-pressure, steam-rich, and heavy-dust operating conditions.

This rigorous approach—control at the design stage, verification through systematic testing, and validation under real industrial scenarios—enables Jiwei’s products to maintain stable performance even in applications where many international brands hesitate to make firm commitments. As a result, Jiwei has earned growing trust across a wide range of industries.

4. Industry-Specific Engineering: Designed for Real Working Conditions

Instead of offering “one universal model for all applications,” Jiwei focuses on industry-tailored optimization, designing probes, materials, circuits, and algorithms specifically for different process environments.

4.1 Food Industry (Chili Sauce, Tomato Paste, Starch, Syrups)

Challenge: Viscous media cause adhesion, buildup, and false switching.

Jiwei solution:

- Anti-fouling probe geometry

- Special low-adhesion coatings

- High-sensitivity tuning for slow-flowing media

- Sealed hygienic process connections

4.2 Feed, Grain, and Bulk Solids

Challenge: Heavy dust load, vibration, and material impact.

Jiwei solution:

- Anti-dust rotating paddle switches

- Reinforced bearings and torque structures

- High-vibration-resistant electronics

- Adaptive anti-flutter algorithms

4.3 Petrochemical Industry

Challenge: Hazardous areas, corrosive media, strict compliance standards.

Jiwei solution:

- NAMUR two-wire interface

- Intrinsically safe Ex ia circuits

- 316L corrosion-resistant structures

- SIL functional safety diagnostics

4.4 Marine & Shipbuilding

Challenge: High humidity, salt mist, corrosion, long service lifetime.

Jiwei solution:

- 304/316L stainless steel housings

- Marine-grade sealing

- Anti-condensation design

- Salt spray verified components

4.5 Steel, Metallurgy & High-Temperature Applications

Challenge: Shock, heat waves, severe dust, and mechanical impact.

Jiwei solution:

- Impact-resistant heavy-duty probes

- Up to 400°C temperature tolerance

- Thermal isolation structures

- High-power sensing output

Each adaptation is engineered, not simplified—ensuring that sensors are not only functional but optimized for the realities of actual industrial sites.

5. Reliability Track Record

Jiwei’s instruments have accumulated a large number of long-term field cases. A notable example:

Such data-driven cases form the basis of Jiwei’s reliability claims, replacing marketing slogans with verifiable long-term performance.

6. Radar Level Measurement Innovation

Jiwei has also invested heavily in radar technology, including:

- Pulse radar algorithms

- Waveform analysis

- False-target suppression

- Steam and dust penetration optimization

- High dynamic range echo processing

- Temperature drift compensation

One of Jiwei’s newest developments includes: a fully in-house engineered radar level transmitter equipped with true Bluetooth connectivity for configuration and diagnostics, designed for high stability across dust, steam, and condensation environments.

7. Manufacturing Excellence & Quality Assurance

To ensure consistency across every product line, Jiwei maintains independent calibration facilities, automated production fixtures, and a 100% functional testing regime. Environmental simulation chambers replicate extreme conditions—temperature, humidity, vibration, salt spray, dust, and steam—to verify long-term stability. Rigorous incoming material inspections and full unit-level traceability further reinforce quality assurance from the ground up.

This comprehensive quality system allows Jiwei to deliver reliability on par with long-established international manufacturers, while providing the engineering agility and customization capability that mainstream suppliers often cannot offer.

8. Conclusion: A New Path for High-Reliability Level Measurement Engineering

Shenzhen Jiwei Automations demonstrates how a vertically specialized engineering company can achieve true technological depth. Through complete R&D independence, full-chain product design capabilities, and industry-specific customization, Jiwei has built a development system that prioritizes long-term reliability over short-term output. Its instruments operate stably even in extreme environments and maintain consistent performance across large-scale deployments.

By choosing technical depth over diversification and engineering rigor over marketing-driven expansion, Jiwei represents the emergence of a new generation of high-reliability, fully in-house engineered instrumentation manufacturers from China—companies capable of contributing meaningfully to the global process automation landscape.