Why Instrumentation Engineering Matters: The Core of Industrial Control

Introduction: Is Instrumentation Just Wiring and Configuration?

To many junior engineers, instrumentation seems like a hands-on job—running cables, mounting sensors, tuning devices. But engineers who truly influence system architecture ask deeper questions:

- Who defined these measurement points?

- Is this signal path sufficient for reliable closed-loop control?

- Can a vendor bypass our system logic through a digital interface?

If you think instrumentation is only about measurement, you’re missing the point. Instrumentation is the industrial system’s primary interface with the physical world—its sensory front line, and the very beginning of data sovereignty.

Let’s take two real-world scenarios:

- A level transmitter on a reactor delays feedback by just 2 seconds—the PID loop begins to drift, overfeeds chemicals, and risks triggering an emergency shutdown.

- A remote pumping station mistakenly reads an “empty” signal from a level switch—wasting hundreds of megawatt-hours by cycling equipment unnecessarily.

In both cases, signal configuration and interface logic—not just device performance—are at fault. And these are decisions made by the system designer, not the field technician.

The Three-Dimensional Capability Model of Instrumentation Engineers

Why do so many instrumentation professionals stay stuck in the “executor” role, even after years of fieldwork? The answer: they haven’t built a system-level mental model of their work.

Here’s how we recommend constructing your Instrumentation Capability Map:

1. Physics + Electrical Signal Interpretation

Do you really understand how your selected sensor works?

- How does an RF admittance level switch differentiate between build-up and true material presence?

- Why must guided wave radar be used in steam-heavy tanks?

- How do you compensate for density variation in hydrostatic level measurement?

If you can’t connect physical principles with instrumentation behavior, you’ll always rely on trial-and-error—or worse, vendor advice with hidden agendas.

2. Control System Architecture + Communication Infrastructure

Every instrument is part of a broader system. Ask yourself:

- How are I/O points distributed between PLC, DCS, and remote I/O islands?

- How do you map signal types (HART, Modbus RTU/TCP, PROFIBUS, 4–20 mA) onto redundant ring topologies?

- Is your radar level transmitter’s echo diagnostic feeding into your AMS or APM system?

Only by understanding system architecture can you meaningfully contribute to control strategy and failure diagnostics.

3. Engineering Workflow + Project Coordination

Instrumentation spans multiple disciplines—far beyond P&ID drawing and loop checking:

- Collaborating with electrical teams on control cabinet and power cabinet segregation

- Supporting process engineers in defining measurement positions and dynamic ranges

- Coordinating with procurement on delivery cycles, vendor evaluation, and equivalent replacements

Your early involvement often determines the system’s maximum performance ceiling.

You’re Not Just “Tuning a Device”—You’re Defining System Boundaries

Most instrumentation failures stem from poor boundary definitions, not device defects.

Case 1:

An RF admittance switch triggered constant false alarms. Multiple replacements failed. The root cause? Poor grounding caused electrostatic interference—not a sensor defect.

Case 2:

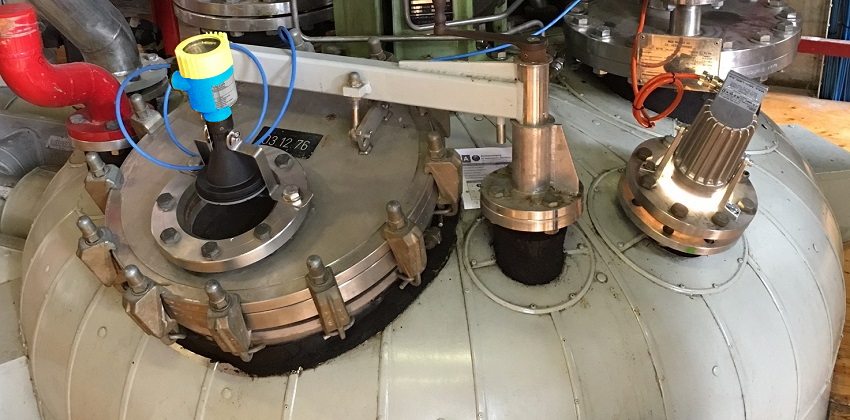

Radar level readings in a high-pressure tank were inconsistent. Diagnostics showed signal loss due to steam bursts near the antenna, resolved only by switching to guided wave radar.

Case 3:

A pressure transmitter kept dropping offline. Turns out the PLC analog card had no Fail-safe configuration after power loss—default values triggered emergency shutdowns.

These problems can’t be solved by simply “changing devices.” They require a systems mindset.

From Field Engineer to System Architect: The Instrumentation Career Path

Career growth in instrumentation follows a shift in thinking—from local tasks to global logic.

- Executor: Install and calibrate instruments as instructed

- Interpreter: Understand why devices are selected and how they affect control

- Definer: Design measurement strategies and data chains

- Coordinator: Lead multi-discipline teams, oversee bids, and direct execution

If you never go beyond “installation and testing,” you’ll miss the real leverage: system definition and control authority.

Build Your Engineering Asset Library—Now

Don’t rely on scattered PDFs or vendor WhatsApp groups. Build your own knowledge base:

- Selection Map: Categorize sensors by media, pressure, temperature, and signal requirements

(e.g., capacitive vs. ultrasonic vs. radar for level detection) - Control Templates: Capture typical PID loops, multi-tank switching, interlocks

- Failure Models: Document failure signatures and their root causes

- SOP Library: Create standardized procedures for commissioning, loop testing, HART diagnostics

This becomes the foundation of your system engineering capability—and your value as a project leader.

Instrumentation: The Sensory Core of the Industrial Brain

That guided wave radar you’re installing? It isn’t just feeding a tank level—it’s anchoring feedstock control, blending logic, and safety interlocks.

That RF admittance switch isn’t just toggling on/off. It might be preventing material bridging, protecting mechanical conveyors, or avoiding unexpected downtime.

Each signal wire you connect is a thread in the fabric of industrial decision-making. The sooner you understand that, the sooner you evolve from technician to system strategist.

Closing Thoughts

You’re not just installing a level switch—you’re establishing the foundation of autonomous operation.

If you feel stuck in low-value work, begin your transition with these four actions:

- 📘 Study: Choose a core instrumentation textbook and dive deep into signal principles

- 👀 Observe: Shadow a senior systems engineer and learn how decisions are made

- ✍️ Document: After every project, capture not just what happened—but why

- 🤔 Reflect: Ask yourself daily: “Did I understand more of the system today than yesterday?”

Three years from now, you’ll no longer be “just an instrument guy.” You’ll be the one defining how the plant thinks.