2‑Wire vs 4‑Wire Wiring in Instrumentation

In modern instrumentation, the wiring method used for field devices is often overlooked but critically important. Among the most common wiring schemes in process instrumentation, the 2‑wire and 4‑wire systems not only differ in conductor count but also impact power delivery, signal accuracy, system stability, and total installation cost.

This article explains the principles, differences, and application strategies of 2‑wire vs. 4‑wire wiring in instrumentation, so engineers can make better decisions in real-world projects.

1. What Exactly Are 2‑Wire and 4‑Wire Systems in Instrumentation?

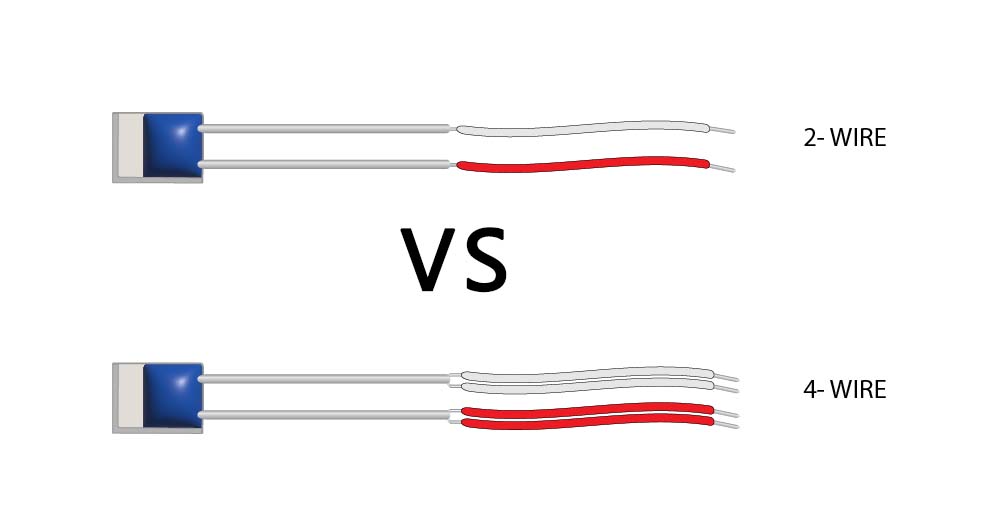

1.1 What is a 2‑Wire System?

In a 2‑wire configuration, a pair of wires is used both to power the transmitter and carry the output signal. The signal typically uses the 4–20mA current loop standard. The entire circuit forms a series loop:

24V Power Supply → Transmitter → PLC or Control System

The transmitter internally converts the measured physical value into a current signal superimposed on the power loop.

Advantages:

- Simplified wiring

- Lower cost and space requirements

- Ideal for applications with dispersed field points or large device counts

1.2 What is a 4‑Wire System?

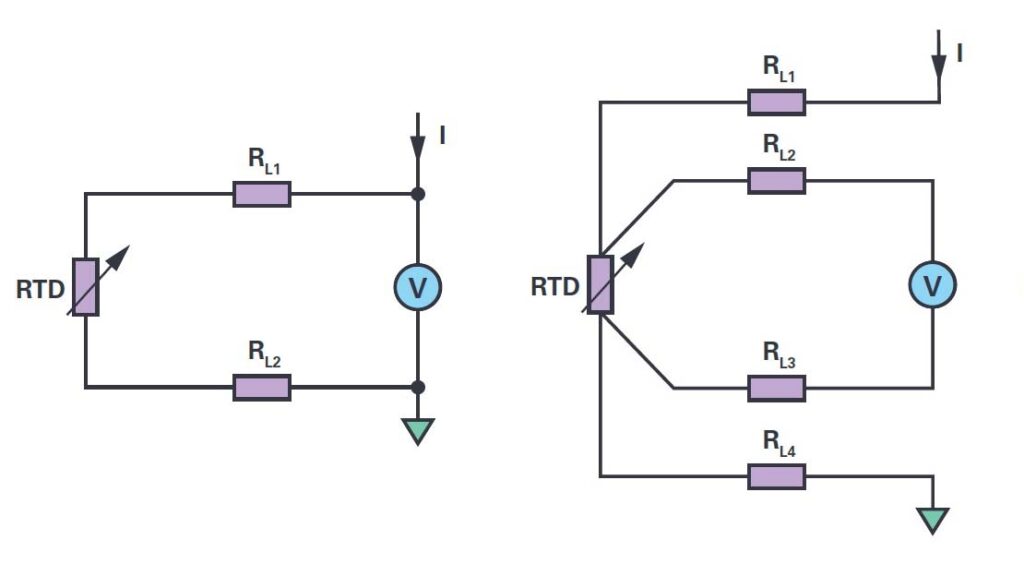

In 4‑wire setups, two wires are used solely for power (e.g., 24V DC or 220V AC), while the other two are dedicated to signal output, which may be analog or digital.

This physical separation ensures minimal interference and supports devices with higher power demands such as those with displays, heating units, or internal computing.

Advantages:

- Supports high‑power instrumentation

- Greater signal accuracy

- Stronger noise immunity

- Suitable for complex industrial environments

2. Five-Dimensional Comparison in Instrumentation Context

| Factor | 2‑Wire System | 4‑Wire System |

|---|---|---|

| Wiring Complexity | Fewer wires; easy to install; cost-effective | More complex; better for centralized setups |

| Power Capability | Limited to 24V × 20mA (~0.48W) | Supports high-power devices (e.g., 220V/100mA) |

| Signal Accuracy | Moderate; can be compensated over long distances | High precision and stability; strong EMI immunity |

| Application Type | Pressure, temperature, level transmitters | Mass flow meters, gas analyzers, multifunction instruments |

| Maintenance | Shared power and signal lines; harder to troubleshoot | Separate lines; easier fault location and maintenance |

3. How to Select the Right Wiring Method for Instrumentation?

A simple three-step strategy helps determine the right choice:

Step 1: Evaluate Power Consumption

- If the instrument’s power requirement is below 0.5W, a 2‑wire system is usually adequate (e.g., pressure transmitters).

- For >1W devices like gas analyzers or flowmeters with heaters, choose a 4‑wire setup.

Step 2: Consider Accuracy Demands

- For general monitoring (±0.5% accuracy), such as in water treatment or HVAC, 2‑wire systems suffice.

- For trade metering or pharmaceutical-grade applications requiring ±0.1% accuracy or better, 4‑wire is a must.

Step 3: Assess Wiring Conditions

- In large-scale field installations with wiring difficulty, go with 2‑wire to reduce costs.

- For centralized systems or where space is available, 4‑wire offers better long-term reliability and serviceability.

4. Real-World Instrumentation Case Studies

Case 1: Chemical Plant Installing 100 Pressure Transmitters

Using 2‑wire connections saved over 2,000 meters of cable, reducing costs by more than 30%. Even with distances up to 500 meters, signal errors remained within ±0.3%, well within operational tolerance.

Case 2: Refinery Trade Metering with Mass Flow Meters

Due to high internal power demands and ±0.1% accuracy requirements, 4‑wire wiring (220V AC + signal lines) was adopted. The system ran reliably for 5 years with no failures, meeting national metrology standards.

5. Final Takeaway: The Best Choice Is the Most Suitable One

It’s not about more wires being better — it’s about the right fit.

- 2‑wire systems shine in simplicity, cost-efficiency, and ease of deployment, making them ideal for over 90% of field instrumentation setups.

- 4‑wire systems are designed for precision-critical, high-power, and interference-heavy environments.

Next time you’re selecting a wiring strategy, don’t just count wires. Ask:

- How much power does the instrument need?

- What accuracy level is required?

- How challenging is the field wiring?

The answers will guide you to the right instrumentation solution.