Jiwei Vibrating Fork Level Switch: Setting a New 280°C Standard for Industrial Measurement

Shenzhen Jiwei Automations Ltd. is proud to announce the latest performance upgrade for its flagship product — the Ring-11 vibrating fork level switch. This new enhancement extends the operational temperature range to 280°C, enabling the device to function reliably in even more extreme conditions. This upgrade represents a significant milestone, positioning the Ring-11 as an industry leader in both reliability and environmental adaptability, particularly in high-temperature environments where few alternatives can perform at this level.

Ring-11: The New Benchmark for Level Measurement Technology

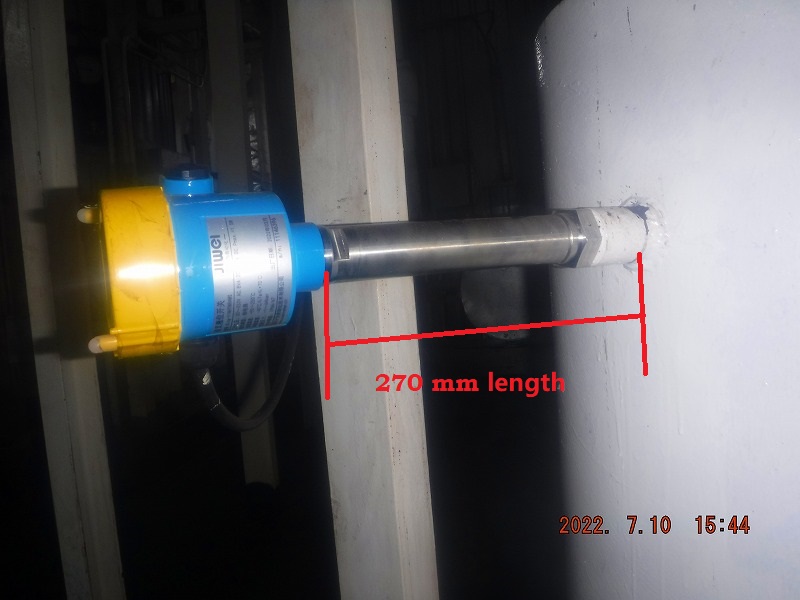

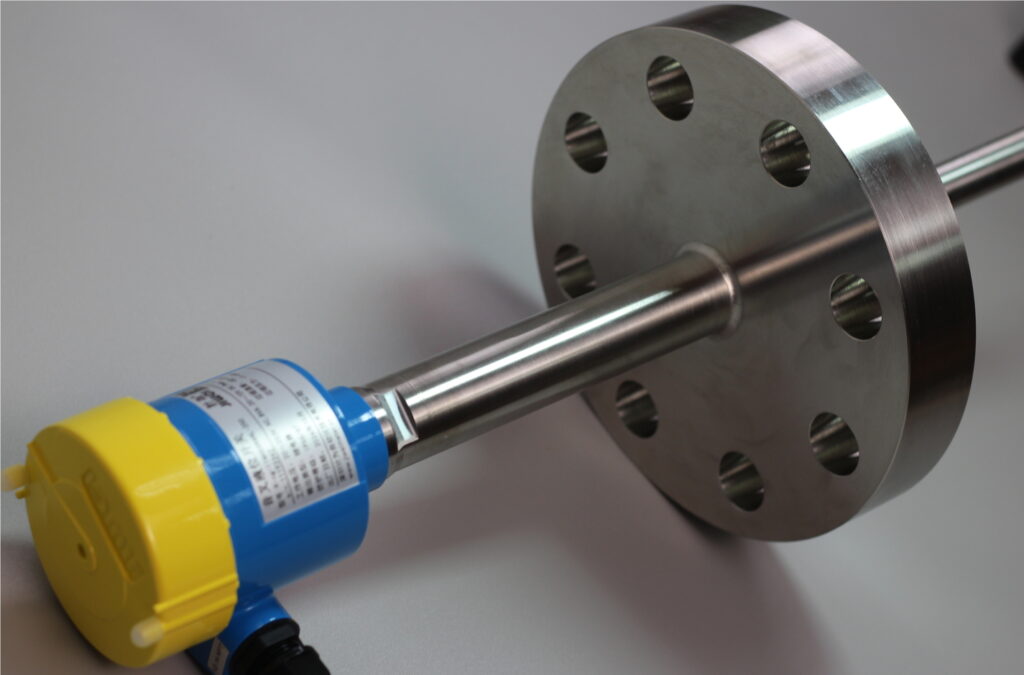

The Ring-11 is an intelligent level control switch designed for use in various containers, tanks, silos, and pipelines. It finds widespread application in industries such as water resources, chemical engineering, environmental protection, food, and pharmaceuticals. The core technology of the Ring-11 is based on the piezoelectric principle, where the vibrating fork vibrates through a piezoelectric element. Upon contact with the liquid, the vibration frequency changes due to the damping effect of the liquid, and this change is detected and converted into a stable switching signal. This design eliminates the need for onsite adjustments, ensuring simple and reliable operation.

The Ring-11’s compact design, with a fork length of just 40mm, makes it especially advantageous for space-constrained environments, such as pipelines where space for equipment is limited. This compact design does not compromise its performance. The vibrating fork level switch offers excellent stability and detection capabilities even in challenging conditions such as foam, bubbles, viscous liquids, and strong vibrations, which often disrupt traditional sensors. Its ability to measure materials with a minimum density as low as 0.5g/cm³ ensures that it meets the diverse needs of industries requiring precise liquid and solid level measurement.

Industry-Leading Durability and Safety Features

One of the key highlights of the Ring-11 vibrating fork level switch is its exceptional durability, especially its high-temperature resistance. The device now operates stably in temperatures up to 280°C, making it suitable for use in extreme environments such as steam, hot oil, and chemical reactions. Whether in industrial settings with extreme heat or in other challenging applications, the Ring-11 vibrating fork level switch maintains its superior performance, providing a level of dependability that few other level switches can match.

Additionally, the Ring-11 vibrating fork level switch has earned SIL2/SIL3 functional safety certification and is equipped with both intrinsic safety and explosion-proof certifications. These certifications ensure that the device can be safely used in high-risk applications, offering critical protection in industries where safety is paramount. These features make the Ring-11 a trusted choice for hazardous and volatile environments, including chemical plants, petrochemical industries, and pharmaceutical manufacturing.

Key Features of the Ring-11 Vibrating Fork Level Switch

- Compact and Precise: The short fork design of just 40mm is tailored to fit into small spaces or within pipelines, overcoming the size limitations of traditional level switches. Despite its size, it offers highly accurate level detection.

- Exceptional Environmental Adaptability: The Ring-11 can effectively operate in complex environments with challenges such as foam coverage, bubble interference, viscous media, and high vibration, maintaining stable detection and rapid response.

- High-Temperature Resistance: With a temperature range extended to 280°C, the Ring-11 can withstand the harshest conditions in industries such as high-temperature steam, hot oil systems, and chemical reactors, providing reliable measurements even in extreme heat.

- Versatile Media Compatibility: The Ring-11 can measure liquids and solids with densities as low as 0.5g/cm³, including light liquids, viscous media, and chemical solutions, making it suitable for a wide range of industrial applications.

- Dual Safety Certifications: The device is certified with SIL2/SIL3 functional safety standards and both intrinsic safety and explosion-proof certifications. These certifications make it ideal for use in high-risk environments, offering a reliable safety solution for critical processes.

- Zero Calibration and Maintenance: The Ring-11 requires no on-site calibration and features a maintenance-free operation. It is ready for use straight out of the box, reducing operational and maintenance costs, which is a significant advantage in industrial environments where uptime is critical.

Real-World Applications of the Ring-11 vibrating Fork Level Switch

The Ring-11 is particularly beneficial in industries that deal with complex and demanding conditions. For example, it is widely used in the oil and gas sector, where it can measure liquid levels in high-temperature and high-pressure environments. It is also ideal for use in chemical manufacturing where hazardous substances are involved, ensuring safe and reliable level measurement. In food and pharmaceutical industries, the Ring-11 is essential for ensuring accurate level detection of both liquid and powder materials, contributing to quality control and process efficiency.

Conclusion: Jiwei Automations Leads the Way in Level Measurement Innovation

With this latest upgrade, the Ring-11 vibrating fork level switch sets a new standard in the industry, offering unmatched precision, reliability, and safety. Jiwei Automations continues to innovate and develop products that meet the evolving needs of industries worldwide. The Ring-11’s combination of advanced technology, high durability, and safety certifications positions it as the ideal choice for industrial level measurement applications, especially in extreme environments.

By driving continuous innovation, Jiwei Automations is committed to helping global industrial customers achieve higher levels of automation and control, further solidifying its position as a leader in the field of level measurement.