The Ultimate Guide to Continuous Level Measurement: Reliable Solutions for Every Industry

What is Continuous Level Measurement?

Continuous level measurement provides real-time monitoring of liquids, powders, and bulk solids in tanks and silos. Unlike point level measurement, which detects only high or low levels, continuous level measurement delivers precise readings across the entire range, ensuring process control, inventory management, and operational safety.

Industries such as chemicals, food processing, water treatment, and manufacturing rely on continuous level measurement for accurate material tracking and system automation. It helps prevent material shortages, optimizes resource utilization, and enhances safety by reducing the risk of overfilling or underfilling.

How Does Continuous Level Measurement Work?

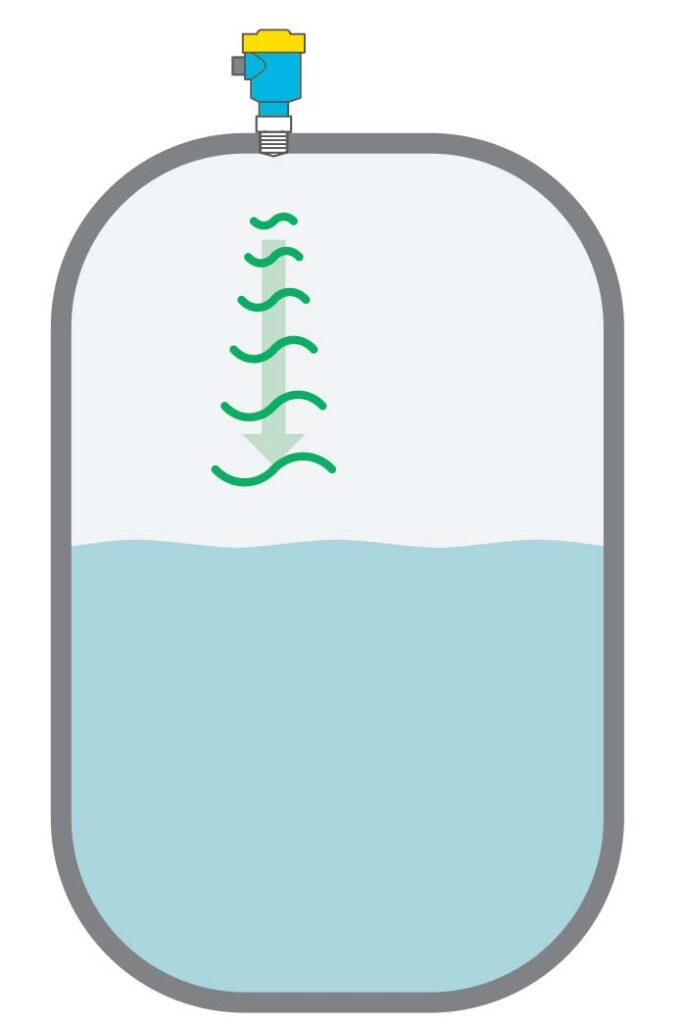

Level sensors convert the height of a material into an electronic signal, which can be displayed locally or integrated into process control systems. The accuracy and reliability of the measurement depend on the selected sensor technology. Different measurement technologies—radar, ultrasonic, and magnetic level transmitters—offer solutions tailored to various materials and environmental conditions, ensuring optimal performance across different industries.

Choosing the Right Technology for Continuous Level Measurement

1. Radar Level Transmitters: Precision with Adaptive Technology

Radar level transmitters use electromagnetic waves to measure level without contact. Jiwei’s radar level transmitters feature an exclusive self-adaptive function, automatically adjusting to changes in environmental conditions such as temperature fluctuations, dust, and vapor interference. This ensures consistently accurate readings without requiring manual calibration.

✔ High Accuracy: Measures up to ±1 mm, even in volatile conditions.

✔ Non-Contact Measurement: Prevents contamination and sensor wear.

✔ Exclusive Adaptive Technology: Adjusts automatically for stable performance.

✔ Resistant to Harsh Environments: Works in corrosive, high-pressure, and high-temperature conditions.

✔ Bluetooth Connectivity: Supports Jiwei Smart Control App for wireless monitoring.

✔ Wide Measurement Range: Capable of measuring levels up to 30 meters, making it suitable for large industrial tanks and silos.

Jiwei’s radar level transmitters provide long-term stability and precise readings, making them ideal for industries requiring high reliability in extreme operating conditions.

Best for: Liquids, powders, and bulk solids in process tanks and silos.

2. Ultrasonic Level Transmitters: Cost-Effective with Explosion-Proof Certification

Ultrasonic level transmitters rely on sound waves to detect levels. Jiwei’s ultrasonic level transmitters come with explosion-proof certification (Ex d IIC T6 Gb), ensuring safe operation in hazardous environments such as chemical processing and fuel storage. Additionally, they support RS485 communication for seamless system integration and offer a split-type design, allowing for flexible installation and easy maintenance.

✔ Explosion-Proof (Ex d IIC T6 Gb): Ensures safety in hazardous areas.

✔ RS485 Communication: Allows real-time data transmission.

✔ Non-Contact Technology: Ideal for clean and non-foaming liquids.

✔ Split-Type Design: Enables easy maintenance and installation.

✔ Durability: Resistant to dust and condensation.

✔ Cost-Effective Solution: A balance of performance and affordability for various industries.

The ability to integrate Jiwei ultrasonic transmitters into existing industrial automation systems makes them a highly versatile option for companies looking for reliable yet economical continuous level measurement solutions.

Best for: Water, chemicals, and non-volatile liquids in open or closed tanks.

3. Magnetic Level Transmitters: Patented Technology with SIL2/3 Certification

Jiwei’s magnetic flap level meters incorporate over 10 national patents, reflecting cutting-edge innovation in continuous level measurement. These transmitters can be equipped with remote transmitters and magnetic switches, allowing them to achieve SIL2/3 functional safety certification. The certification standards comply with industry safety regulations, ensuring reliable operation in critical applications. Additionally, the system supports 4-20mA + HART output, enabling integration into advanced process control systems.

✔ 10+ National Patents: Innovative technology for enhanced performance.

✔ SIL2/3 Certification: Achieved through compatible remote transmitters and magnetic switches.

✔ 4-20mA + HART Output: Seamless integration with industrial automation systems.

✔ Direct Visual Indication: No power supply needed for local readings.

✔ Corrosion-Resistant Materials: Suitable for aggressive chemicals and hazardous liquids.

✔ High Stability and Accuracy: Ensures consistent and precise level readings in critical processes.

The advanced features of Jiwei magnetic level transmitters make them an excellent choice for applications requiring high safety standards, particularly in industries dealing with corrosive and hazardous substances.

Best for: Corrosive and hazardous liquids, oil tanks, and industrial process monitoring.

Why Continuous Level Measurement Matters

Accurate level measurement is critical for:

✅ Process Optimization: Ensures smooth material flow in production lines, reducing downtime and increasing efficiency.

✅ Inventory Management: Prevents overfilling and material shortages, improving production planning.

✅ Safety Compliance: Reduces the risk of spills, overpressure, and equipment failure.

✅ Energy Efficiency: Optimizes material usage and minimizes waste, leading to cost savings.

✅ Regulatory Compliance: Meets industry-specific requirements, ensuring safe and reliable operations.

With continuous level measurement, industries can achieve greater control over their processes, enhancing both safety and efficiency while reducing overall operational costs.

Conclusion

Continuous level measurement is essential for efficient and safe industrial operations. Whether using radar transmitters with exclusive adaptive technology, ultrasonic transmitters with explosion-proof certification, or magnetic level transmitters with patented SIL2/3-certified solutions, Jiwei offers industry-leading accuracy and reliability.

By choosing the right level measurement technology, businesses can improve process efficiency, enhance safety compliance, and optimize resource management. Jiwei’s advanced solutions provide unmatched performance, making them the ideal choice for industries requiring robust and precise level measurement.

Invest in the right level measurement technology to enhance operational efficiency, reduce downtime, and ensure compliance with industry standards.

For tailored solutions, contact Jiwei today!