Protective Coatings for Level Switches: Selection, Applications, and Field Practices

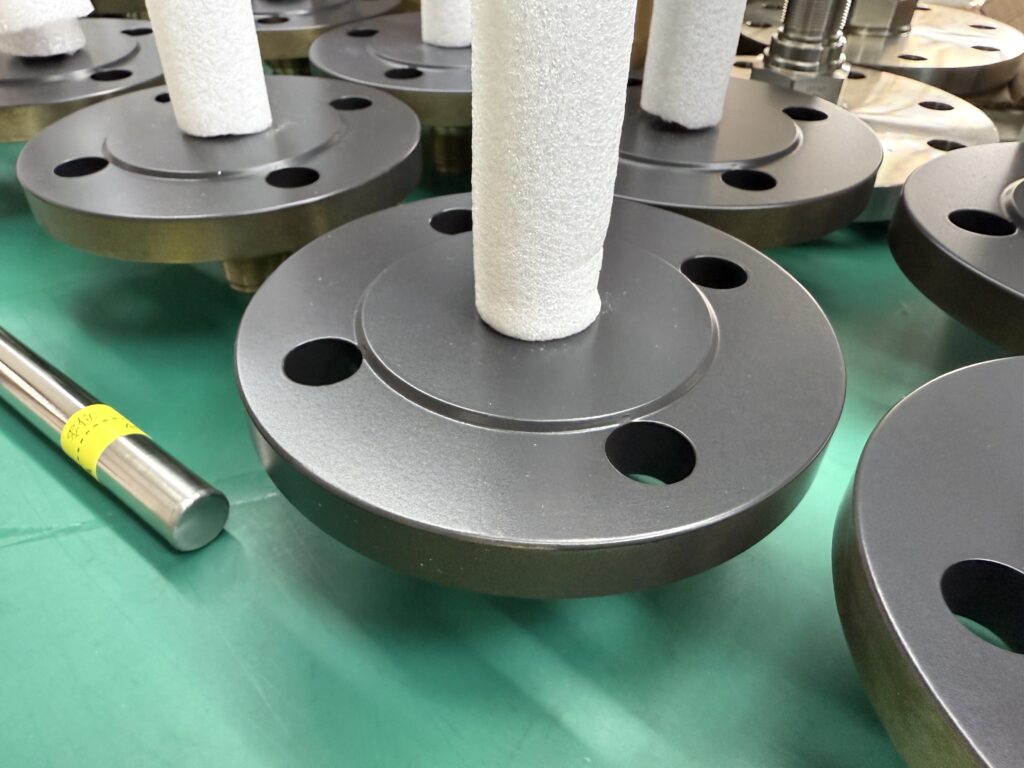

In industrial automation, level switches are essential for ensuring equipment safety, process control, and stable production. They are widely used in chemical, food, pharmaceutical, and new energy industries, where they often come into direct contact with highly corrosive, high-temperature, or viscous media. Without proper protection, level switches can suffer from corrosion, material buildup, or premature failure, impacting safety and operational efficiency. To address these challenges, Shenzhen Jiwei Automations applies protective coatings to the parts of level switches that contact process media. Common coatings include enamel (ceramic), ECTFE, and PFA, each selected based on the medium, temperature, and required long-term stability.

Common Protective Coatings and Their Characteristics

| Coating Type | Characteristics | Sintering Temperature (℃) | Continuous Use Temperature (℃) | Suitable Applications |

|---|---|---|---|---|

| Enamel (Ceramic) | Smooth, fine surface, high corrosion and temperature resistance, tightly bonded, crack-resistant | High | Up to 260 | Strong acids, strong bases, high-temperature liquids |

| ECTFE | Excellent corrosion resistance, easier to process, moderate cost | 250–270 | ≤150 | Room temperature, mild corrosive media |

| PFA | Superior high-temperature and corrosion resistance, strong mechanical toughness, complex process | 380–400 | ≤260 | Highly corrosive, high-temperature environments requiring long-term stability |

Notes:

- Sintering temperature refers to the high-temperature process needed to form the coating.

- Continuous use temperature indicates safe long-term operation in contact with process media.

Engineering Significance of Protective Coatings

1. Enamel (Ceramic) Coating

Enamel coating is formed by uniformly applying a ceramic material to a metal surface, then sintering it at high temperature. Its key advantages include:

- Corrosion resistance: Effective against most acids, bases, and salt solutions.

- Smooth surface: Minimizes material adhesion and facilitates cleaning, ideal for food and chemical applications.

- High-temperature tolerance: Withstands short-term high-temperature exposure.

- Manufacturing complexity: High sintering temperature and precise process increase cost but ensure long-term durability.

2. ECTFE Coating

ECTFE (ethylene-chlorotrifluoroethylene) is a fluoropolymer coating suitable for low to moderate temperature applications:

- Excellent corrosion resistance: Suitable for room-temperature acid and alkaline solutions.

- Ease of processing: Lower sintering temperature than PFA, simpler manufacturing.

- Cost-effective: Moderate cost for standard industrial applications.

- Limitation: Continuous use temperature ≤150℃; not ideal for high-temperature corrosive environments.

3. PFA Coating

PFA (perfluoroalkoxy) coating offers the best combination of high-temperature and corrosion resistance, used for demanding applications:

- Superior corrosion resistance: Effective against almost all acids, bases, and high-chloride solutions.

- High-temperature performance: Safe for continuous operation up to 260℃.

- Mechanical toughness: Resistant to cracking and impact, suitable for high-vibration or high-flow pipelines.

- High cost and complexity: Sintering process is demanding, but provides long-term protection for critical applications.

Selecting the Right Coating

When selecting a protective coating, consider the following factors:

- Chemical Industry: Strong acids, bases, and high-temperature solutions; PFA or enamel coatings recommended for corrosion and heat resistance.

- Food & Beverage Industry: Milk, wort, fermentation liquids; enamel or ECTFE coatings provide smooth, easy-to-clean surfaces.

- New Energy Industry: Lithium battery slurries and precursor materials; PFA coatings resist adhesion and corrosion.

- Mild Corrosion & Room Temperature Applications: ECTFE coatings are sufficient and cost-effective.

Tip: Evaluate medium temperature, pressure, concentration, and operating cycles to avoid under- or over-protection.

Field-Proven Performance

Chemical Industry: PFA-coated Ring-11 level switches have operated for years in strong acid and alkali tanks without visible corrosion or false alarms, improving safety.

Food Industry: In breweries and high-sugar wort lines, enamel and ECTFE coatings reduce material buildup and maintenance frequency compared to uncoated devices.

New Energy Industry: PFA-coated level switches resist corrosion and adhesion in lithium battery slurry handling, significantly lowering false alarms and improving automation reliability.

Maintenance Note: Despite high-performance coatings, periodic inspection and cleaning are still necessary to ensure long-term stable operation.

Summary

Level switches in industrial environments face harsh conditions that demand high material and process standards. By using enamel, ECTFE, and PFA coatings, Shenzhen Jiwei Automations enhances corrosion resistance, temperature tolerance, and anti-adhesion properties:

- Enamel: High-temperature, highly corrosive environments, long-term stability.

- ECTFE: Room temperature, mild corrosive media, cost-effective and reliable.

- PFA: High-temperature, highly corrosive media, excellent durability.

Combining material science, precise manufacturing, and engineering experience ensures that Jiwei level switches maintain reliable, long-term performance in chemical, food, and new energy applications. Proper selection of protective coatings not only extends instrument life but also safeguards production continuity and equipment safety.